Roll Crusher

Whether you are processing run-of-mine coal in an underground chamber or requiring precise particle sizing for a fluid bed boiler, the right crushing technology determines your profitability.

At CSTMG, we specialize in advanced Mining Roll Crushers, specifically Mineral Sizers (Double Toothed) and Four Roll Crushers, designed to outperform traditional compression crushers in energy efficiency and material quality.

APPLICATIONS

Coal

Mining

Hot Sale Mining Roll Sizer Crusher

CSTMG roll crushers take a smarter approach. By utilizing a low-speed, high-torque principle combined with shearing and tensile forces, our roll crusher “cuts” the material rather than obliterating it. This results in a uniform product size with minimal dust generation.

Furthermore, this design is exceptionally forgiving of moisture. If you deal with wet, sticky coal or clay-rich ores that typically clog standard machines, our roll crushers are the operational solution you’ve been looking for.

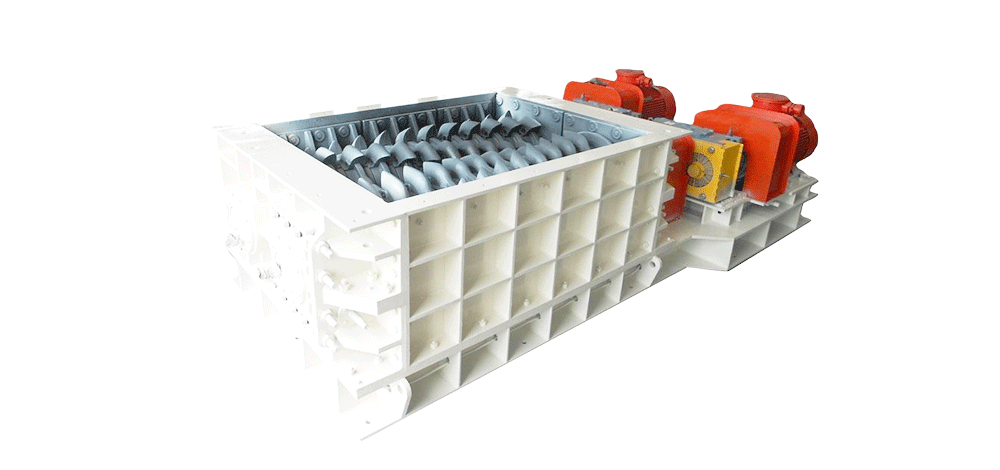

Double Roller Sizer Crusher

Ideal for primary / secondary minerals crushing; Suitable for business requires massive throughput, handles large feed sizes, or operates in restricted underground spaces

Feed Size: ≤1500mm

Output Size: ≤300mm

Capacity: up to 10,000t/h

Four Roll Crusher

Suitable for fine minerals crushing; Reduces material to a fine particle size in a single machine pass with high precision

Feed Size: ≤300mm

Output Size: ≤10mm

Capacity: up to 800t/h

CSTMG Roll Crusher Features

Wide Material Adaptability. Equipped with interchangeable teeth (straight/spiral/wolf-tooth) for coal, limestone, and gangue. Handles materials up to 150MPa hardness and 25% moisture, excelling in brittle/soft ore crushing.

Dual Function. They both possess built-in screening capabilities. The double roller sizer crusher uses tooth geometry to screen out undersize material before crushing, while the four roll crusher utilizes the gap between rollers to control final sizing. This eliminates the need for separate screening equipment in many layouts.

Wide Application. Both are core solutions for the mining, coal, power, and construction material industries. They are standard fixtures in open-pit mines, coal washing plants, and thermal power stations.

Protection & Adjustment. Both feature overload protection mechanisms and allow for flexible output size control by adjusting the roller gap. Their modular designs facilitate easy maintenance and they both handle materials with certain moisture content well.

CSTMG Double Roll Crusher Specification

| Primary Double Roll Crusher Mineral Sizer | ||||

| 150 Series Primary Mineral Sizer | ||||

| Model | CSTMG – 2PLF-150/250 | CSTMG – 2PLF-150/300 | CSTMG – 2PLF-150/350 | CSTMG – 2PLF-150/400 |

| Roller Diameter(mm) | 1500 | 1500 | 1500 | 1500 |

| Roller Length(mm) | 2500 | 3000 | 3500 | 4000 |

| Input Size(mm) | ≤1500 | ≤1500 | ≤1500 | ≤1500 |

| Output Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 |

| Capacity(t/h) | ≤4500 | ≤5500 | ≤6500 | ≤7500 |

| 140 Series Primary Mineral Sizer | ||||

| Model | CSTMG – 2PLF-140/200 | CSTMG – 2PLF-140/250 | CSTMG – 2PLF-140/300 | CSTMG – 2PLF-140/350 |

| Roller Diameter(mm) | 1400 | 1400 | 1400 | 1400 |

| Roller Length(mm) | 2000 | 2500 | 3000 | 3500 |

| Input Size(mm) | ≤1400 | ≤1400 | ≤1400 | ≤1400 |

| Output Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 |

| Capacity(t/h) | ≤3000 | ≤4000 | ≤5000 | ≤6000 |

| 120 Series Primary Mineral Sizer | ||||

| Model | CSTMG – 2PLF-120/150 | CSTMG – 2PLF-120/200 | CSTMG – 2PLF-120/250 | CSTMG – 2PLF-120/300 |

| Roller Diameter(mm) | 1200 | 1200 | 1200 | 1200 |

| Roller Length(mm) | 1500 | 2000 | 2500 | 3000 |

| Input Size(mm) | ≤1200 | ≤1200 | ≤1200 | ≤1200 |

| Output Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 |

| Capacity(t/h) | ≤1500 | ≤2000 | ≤2500 | ≤3000 |

| 100 Series Primary Mineral Sizer | ||||

| Model | CSTMG – 2PLF-100/120 | CSTMG – 2PLF-100/150 | CSTMG – 2PLF-100/200 | CSTMG – 2PLF-100/250 |

| Roller Diameter(mm) | 1000 | 1000 | 1000 | 1000 |

| Roller Length(mm) | 1200 | 1500 | 2000 | 2500 |

| Input Size(mm) | ≤1000 | ≤1000 | ≤1000 | ≤1000 |

| Output Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 |

| Capacity(t/h) | ≤800 | ≤1200 | ≤1500 | ≤2000 |

| Secondary Double Roll Crusher Mineral Sizer | ||||||||||

| 100 Series Secondary Mineral Sizer | ||||||||||

| Model | CSTMG – 2PLF-100/150 | CSTMG – 2PLF-100/200 | CSTMG – 2PLF-100/250 | CSTMG – 2PLF-100/300 | CSTMG – 2PLF100/350 | |||||

| Roller Diameter(mm) | 1000 | 1000 | 1000 | 1000 | 1000 | |||||

| Roller Length(mm) | 1500 | 2000 | 2500 | 3000 | 3500 | |||||

| Input Size(mm) | ≤400 | ≤400 | ≤400 | ≤400 | ≤400 | |||||

| Output Size(mm) | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 | |||||

| Capacity(t/h) | 400-800 | 500-1000 | 650-1200 | 800-1500 | 1000-1800 | |||||

| 80 Series Secondary Mineral Sizer | ||||||||||

| Model | CSTMG – 2PLF-80/150 | CSTMG – 2PLF-80/200 | CSTMG – 2PLF-80/250 | CSTMG – 2PLF-80/300 | ||||||

| Roller Diameter(mm) | 800 | 800 | 800 | 800 | ||||||

| Roller Length(mm) | 1500 | 2000 | 2500 | 3000 | ||||||

| Input Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 | ||||||

| Output Size(mm) | 50-150 | 50-150 | 50-150 | 50-150 | ||||||

| Capacity(t/h) | 300-500 | 400-800 | 500-1200 | 600-1500 | ||||||

| 60 Series Secondary Mineral Sizer | ||||||||||

| Model | CSTMG – 2PLF-60/120 | CSTMG – 2PLF-60/160 | CSTMG – 2PLF-60/200 | |||||||

| Roller Diameter(mm) | 600 | 600 | 600 | |||||||

| Roller Length(mm) | 1200 | 1600 | 2000 | |||||||

| Input Size(mm) | ≤300 | ≤300 | ≤300 | |||||||

| Output Size(mm) | 50-150 | 50-150 | 50-150 | |||||||

| Capacity(t/h) | 200-400 | 250-600 | 300-800 | |||||||

CSTMG Four Roll Crusher Specification

| Model | Max. Input Size (mm) | Output Size (mm) | Capacity (tph) | Power (kw) |

| CSTMG – 4G10-50 | 300 | 0-10 | 50 | 18.5+22 |

| CSTMG – 4G10-70 | 300 | 0-10 | 70 | 2×30 |

| CSTMG – 4G10-90 | 300 | 0-10 | 90 | 37+45 |

| CSTMG – 4G10-100 | 300 | 0-10 | 100 | 2×45 |

| CSTMG – 4G10-140 | 300 | 0-10 | 140 | 45+55 |

| CSTMG – 4G10-150 | 300 | 0-10 | 150 | 2×55 |

| CSTMG – 4G10-170 | 300 | 0-10 | 170 | 55+75 |

| CSTMG – 4G10-200 | 300 | 0-10 | 200 | 75+90 |

| CSTMG – 4G10-250 | 300 | 0-10 | 250 | 90+110 |

| CSTMG – 4G10-300 | 300 | 0-10 | 300 | 2×110 |

| CSTMG – 4G10-350 | 300 | 0-10 | 350 | 110+132 |

| CSTMG – 4G10-400 | 300 | 0-10 | 400 | 2×160 |

| CSTMG – 4G10-450 | 300 | 0-10 | 450 | 160+185 |

| CSTMG – 4G10-500 | 300 | 0-10 | 500 | 185+200 |

| CSTMG – 4G10-550 | 300 | 0-10 | 550 | 2×200 |

| CSTMG – 4G10-600 | 300 | 0-10 | 600 | 2×250 |

| CSTMG – 4G10-650 | 300 | 0-10 | 650 | 250+280 |

| CSTMG – 4G10-700 | 300 | 0-10 | 700 | 2×280 |

| CSTMG – 4G10-800 | 300 | 0-10 | 800 | 280+315 |

CSTMG Roll Crusher Worldwide Cases

CSTMG Four Roller Crusher Successfully Works in Indonesia

CSTMG Double Roll Mineral Sizer Installs in Peru

CSTMG Double Roller Crusher Works in United Kingdom

Roll Crusher Handling Materials

High-Moisture & Sticky Materials. Handles wet coal, clay-rich ores, and sticky minerals (up to 25% moisture) without clogging, thanks to self-cleaning tooth design and non-clogging gaps.

Abrasive & Hard Ores. Crushes iron ore, copper ore, gold ore, quartzite, and slag (hardness ≤ 150MPa) with tungsten carbide teeth (HRC≥65), offering 3x longer wear life than standard crushers.

Friable & Brittle Minerals. Minimizes over-crushing (fines generation <5%) for salt, oil shale, clay, gypsum and limestone, preserving lump product quality for downstream processing.

Mixed & Heterogeneous Feeds. Processes coal with gangue, demolition waste, or recycled concrete efficiently, with adjustable tooth configurations (straight/spiral/wolf-tooth) for optimal fragmentation.

CSTMG Roll Crusher Production Details

Material Selection & Preparation

- Rollers and shafts: Forged from 42CrMo alloy steel with ultrasonic testing for internal defects.

- Teeth: Tungsten carbide tips (HRC≥65) brazed in vacuum furnaces for maximum adhesion.

- Frame: Constructed from NM400 wear-resistant steel (Brinell hardness 400) for extended service life.

Precision Machining

- CNC-controlled milling of critical components with ±0.05mm tolerance.

- Gear machining to AGMA Class 9 standards for smooth power transmission.

- Dynamic balancing to G6.3 grade (vibration ≤2mm/s at full load).

Automated Assembly

- Robotic welding of structural components with post-weld stress relief.

- Laser-aligned bearing installation for perfect shaft concentricity.

- Computer-controlled torque application for all fasteners.

CSTMG Roll Crusher Processable Raw Materials

Double Toothed Sizer Crusher:

- Focus: Primary and secondary crushing of brittle, blocky materials.

- Materials: Coal, coal gangue, limestone, coke, glass, clay. It also handles metal ores like iron, gold, and uranium.

- Strength Limit: Can process materials with compressive strength up to 300MPa.

- Best For: Large coal mines, underground mining or coal preparation plants requiring raw coal sizing.

Four-Toothed Roller Crusher:

- Focus: Secondary and tertiary (fine) crushing of medium-hard and brittle materials.

- Materials: Coal, gangue, coke, limestone, gypsum, and softer metal ores (copper/iron).

- Application: Widely used in open-pit mining, gangue power plants and coal washing plants.

- Precision: Capable of crushing feed directly to ≤10mm or even finer for specific industrial requirements.

Selection Guide: Mineral Sizer vs. Four Roll Crusher

Choosing between these two technologies depends on where the machine sits in your production line and your target output size.

1. Consider Your Space and Stage

If you are at the primary or secondary stage of operations, especially in underground settings where vertical space is limited, the Mineral Sizer is superior. Its modularity allows it to be disassembled, moved through narrow shafts, and reassembled on-site.

Conversely, if you are in a surface plant needing a final product finish, the Four Roll Crusher provides the necessary reduction ratio in one go.

2. Output Requirements

The Mineral Sizer is a volume beast, ideal for reducing large chunks (up to 300mm output) for transport or further processing.

The Four Roll Crusher is a precision instrument, designed to take medium feed and turn it into fine granules (often ≤10mm) immediately.

Quick Comparison Table

| Feature | Mineral Sizer (Double Toothed) | Four Roll Crusher |

| Primary Function | Coarse & Medium Crushing | Fine Crushing (Secondary/Tertiary) |

| Crushing Mechanism | Single-stage Shearing + Screening | Two-stage Sequential Crushing |

| Output Size | Broad range (50-300mm) | Fine precision (8-20mm) |

| Capacity | Ultra-High (up to 10,000 t/h) | Medium (10-800 t/h) |

| Ideal Application | ROM Coal, Mine Mouth, Underground | Power Plants, Coke, Chemical Plants |

| Structural Design | Primarily a double-roller structure. Relies on the gap between teeth for sizing/screening. | Composed of two pairs of rollers (4 total), stacked vertically. No independent screening; relies on two-stage crushing. |

| Crushing Flow | Single-pass. Qualified material is screened out immediately; only oversize material is crushed. | Two-stage continuous. Material passes through upper rollers (coarse) then lower rollers (fine) in one sequence. |

| Core Scenario | Best for Underground/Tight Spaces or primary crushing where low over-crushing is critical. | Best for Surface Operations (Power Plants, Large Mines) requiring direct production of fine particles. |

Frequently Asked Questions

Q: Can these crushers handle wet and sticky material?

A: Yes. This is a core strength of CSTMG roll crushers. Since they do not rely on a solid crushing plate (like a jaw crusher), wet material passes through easily. The Four Roll Crusher also features differential speed rotation which creates a self-cleaning effect, scraping off sticky residue automatically.

Q: What is the wear life of the teeth?

A: Lifespan depends on the abrasiveness of your material. However, CSTMG uses proprietary high-manganese steel and specialized alloy overlays for our teeth, significantly extending life compared to standard castings. We also offer interchangeable tooth patterns tailored to your specific ore.

Q: Can I replace my existing impact crusher with a Mineral Sizer?

A: In many cases, yes. If your goal is to reduce fines and energy consumption while maintaining throughput, replacing an impactor with a Mineral Sizer is an excellent upgrade. Our engineers can simulate your circuit to confirm the benefits.

Q: What is the difference between a Mineral Sizer and a standard Jaw Crusher?

A: The primary difference lies in the crushing principle and the resulting product quality.

A standard Jaw Crusher operates on the principle of compression. It squeezes material between two plates until it shatters. While effective for very hard rock, this crushing action requires significant energy and often causes “over-crushing,” creating a high percentage of waste fines (dust/powder).

In contrast, a Mineral Sizer (Double Toothed Roll Crusher) uses high-torque, low-speed shearing and tensile forces. The teeth actively grab the material and “snap” or “shear” it in tension, which is the weakest point of most rocks. This method is far more energy-efficient—often consuming 30% to 50% less power than compressive crushers. More importantly, it produces a uniform product with minimal fines, which is crucial for maximizing the calorific value of coal and reducing waste in mineral processing.

Q: Can the Four Roll Crusher handle wet and sticky coal?

A: Absolutely. Handling high-moisture material is one of the Four Roll Crusher’s standout features.

Traditional crushers or screeners often suffer from “blinding” or clogging when processing wet coal or clay-heavy ores. To combat this, CSTMG Four Roll Crushers are designed with a self-cleaning mechanism. We often utilize a differential speed design where the rollers rotate at slightly different speeds relative to each other. This speed difference creates a scraping action that prevents material from adhering to the roll surface or packing between the teeth. Additionally, specialized scrapers can be installed to actively clean the roller surface during operation, ensuring continuous throughput even when moisture content is high.

Q: How do I adjust the output particle size on a Double Toothed Roll Crusher?

A: Adjusting the product size on a CSTMG Double Toothed Roll Crusher is straightforward and relies on changing the center distance between the two crushing rollers.

Unlike impact crushers where you might need to change blow bars or screen meshes, our Sizers allow you to mechanically or hydraulically widen or narrow the gap between the rollers.

- To increase particle size: You increase the center distance (the gap).

- To decrease particle size: You reduce the center distance.

This adjustment allows operators to adapt to different market requirements quickly. For more significant changes in reduction ratio or feed characteristics, the modular tooth plates can also be swapped for segments with different tooth profiles (e.g., changing from coarse to fine teeth) without replacing the entire shaft assembly.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.