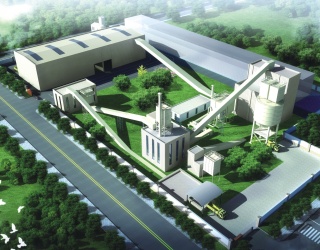

Stone Crushing Plant

CSTMG stone crushing plant offers a complete, high-performance solution for aggregate production. Engineered for maximum efficiency and durability, our plants expertly process hard rock (granite, basalt) and recycled materials (concrete, construction waste). Key advantages include robust construction for low wear costs, high-capacity output with excellent product shape, and energy-efficient operation. Many configurations are available, from stationary to highly mobile units, ensuring a perfect fit for your quarry, mining, or recycling application, maximizing your return on investment.

Hot Sale Stone Crushing and Screening Equipment

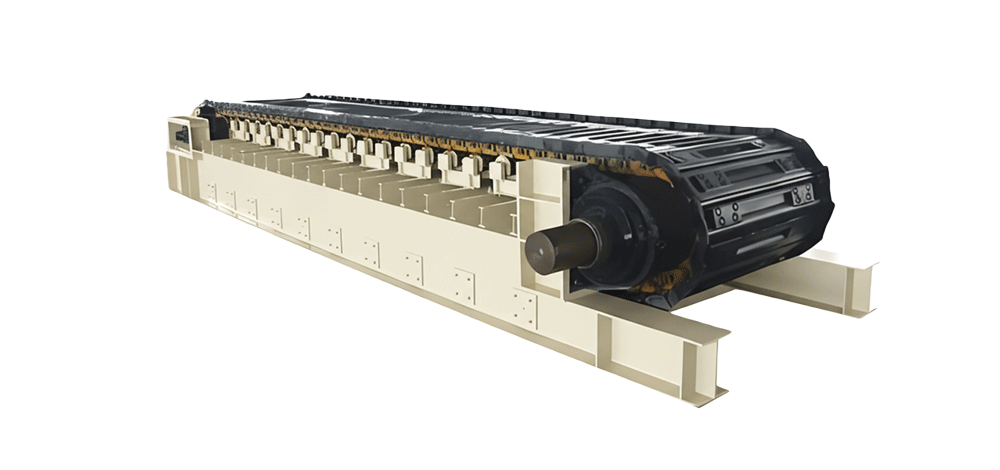

Apron Feeder

Length (m): 2-20

Capacity (m³/h): 50-4,000

Max feeding size (mm): 350-1,800

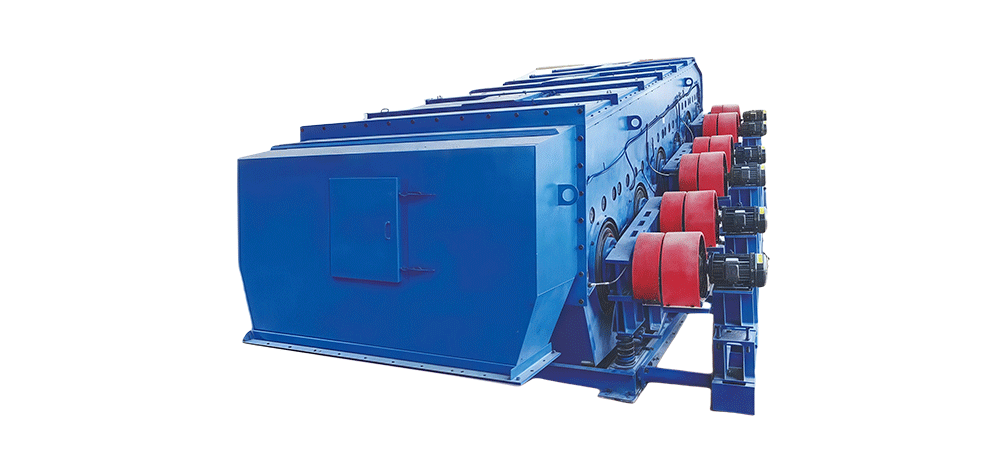

Feeder Breaker

Capacity (t/h): 500-5,000

Conveyor length (m): 6-30

Conveyor width (mm): 1,350-2,750

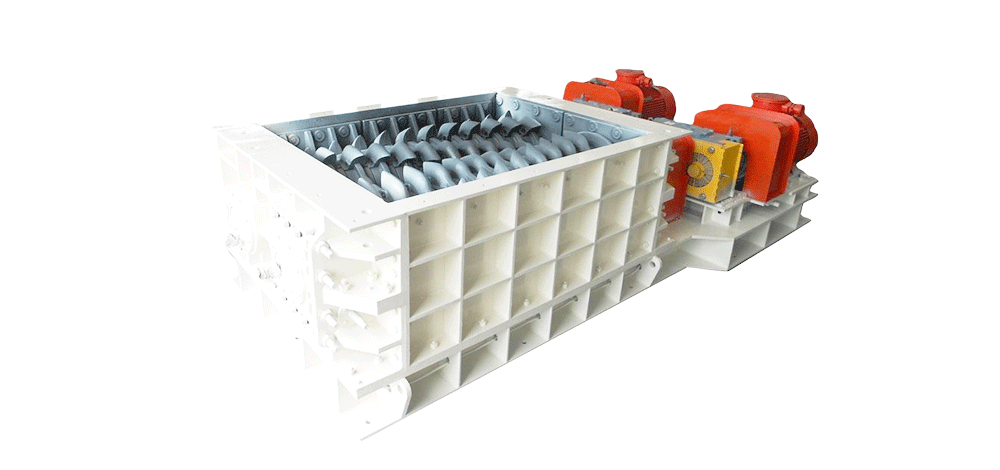

Mineral Sizer

Output size (mm): 50-300

Capacity (t/h): 250-10,000

Max feed size(mm): 200-1,500

Jaw Crusher

Output size (mm): 70-300

Capacity (t/h): 130-1,150

Max feed size(mm): 560-960

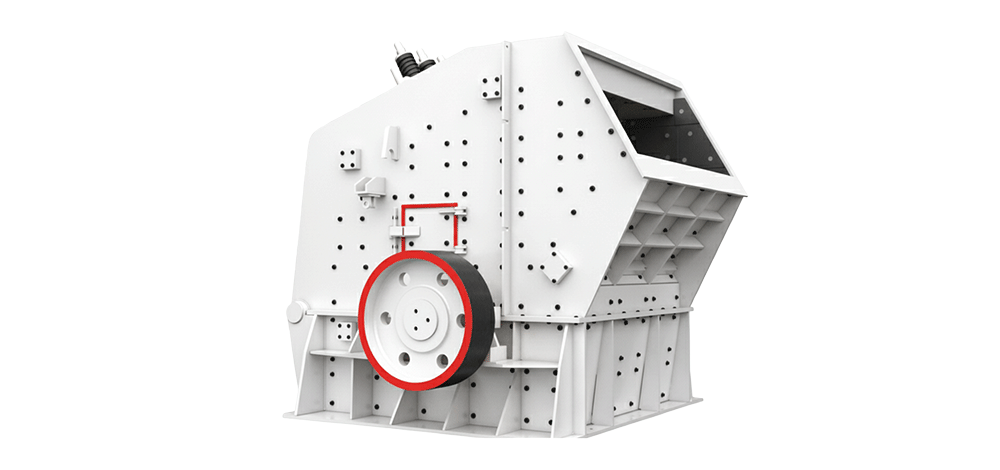

Impact Crusher

Rotor dia (mm): 1,300-1,600

Capacity (t/h): 300-1,000

Max feed size(mm): 600-800

Cone Crusher

Capacity (t/h): 27-1,270

Min. discharge size (mm): 9-38

Type: Single / Multi Cylinder

Hammer Crusher

Rotor dia (mm): 1,600-3,000

Capacity (t/h): 200-5,500

Max feed size(mm): ≤700-≤1,100

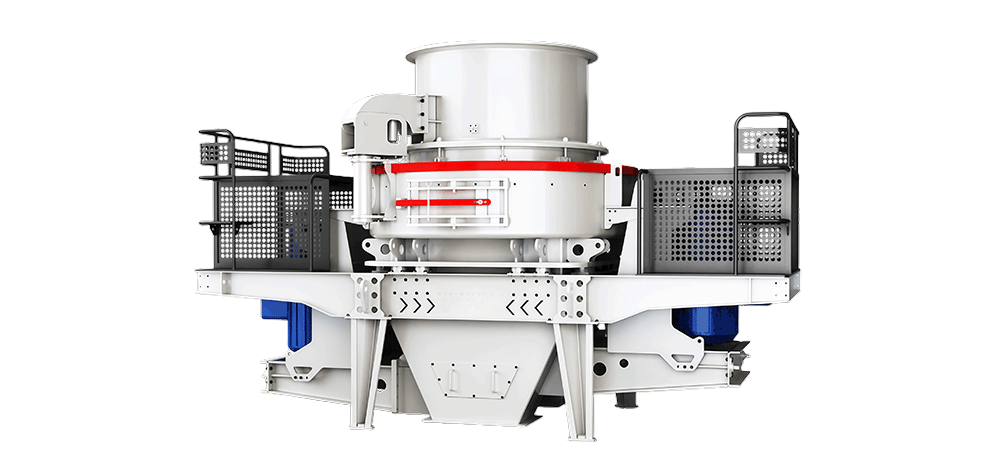

VSI Crusher

Capacity (t/h): 160-600

Max. input size (mm): 40-60

Rotating speed (rpm): 900-1,500

Mobile Crusher Plant

Capacity (t/h): 5-1,000

Feeding Size (mm): 0-350

Type: Crawler/Wheeled

Roller Screen

Capacity (t/h): 150-1,800

Screen Width (mm): 1,200-2,400

Graded Particle Size (mm): 10-100

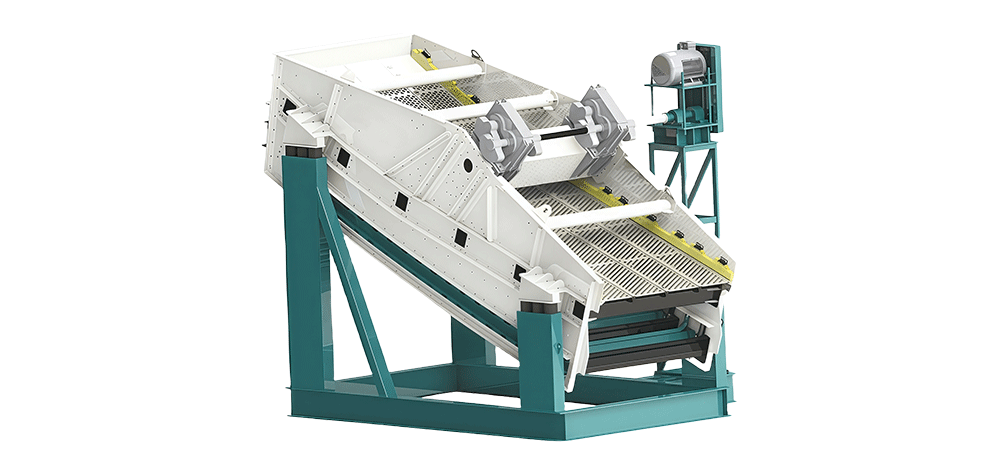

Flip Flow Screen

Capacity (t/h): 150-1,400

Feed size (mm): ≤80-≤100

Type: Mechanical/Vibrating

Circular Vibrating Screen

Number of Layers: 2-3

Capacity (t/h): 60-1,500

Max Input Size (mm): 200

Linear Vibrating Screen

Number of Layers: 1-2

Capacity (t/h): 40-950

Max Input Size (mm): 100

Environmental Screen

Number of Layers: 2-3

Capacity (t/h): 120-1,300

Max Input Size (mm): 200

VSI Crusher

Capacity (t/h): 120-520

Soft material max. feed size (mm): 35-60

Hard material max. feed size (mm): 30-50

CSTMG Stone Crushing Plant Structure

Each module of CSTMG stone crushing plant plays a critical role in the seamless transformation of raw material into high-value, graded aggregates. Material is fed into a primary crusher (Jaw crusher) for initial size reduction. The output is then screened; correctly sized material is sent to stockpiles. Oversized material is automatically conveyed back to a secondary crusher (Cone/Impact crusher) for further crushing. This continuous cycle of crushing, screening, and recirculating ensures highly efficient processing and maximum yield of precisely graded final aggregates, all with minimal manual intervention.

Feeding

The Feeding System ensures uniform and consistent delivery of raw materials like rock and recycled concrete to the primary crusher. Its core component, the Vibrating Grizzly Feeder (VGF), performs scalping to remove fines and evenly feeds larger material. This protects the crusher from shock loads, optimizes capacity, and prevents blockages. Pre-treatment options, such as metal detectors or rock breakers, handle impurities or oversized feed, safeguarding downstream equipment and enhancing overall crushing efficiency and product quality.

Types of CSTMG Feeding Equipment

Crushing

The crushing system is the plant’s core, where raw material undergoes multi-stage size reduction. Primary crushing, handled by a robust Jaw Crusher, breaks down large rocks into manageable chunks. Secondary crushing, performed by either a Cone Crusher for hard, abrasive rocks or an Impact Crusher for softer stone and recycling, further reduces size and is crucial for shaping a high-quality, cubical final product. This tailored equipment combination ensures efficient processing for any material type.

Types of CSTMG Crushing Equipment

Screening

The screening system precisely separates crushed material into defined size fractions (e.g., 0-5mm, 5-10mm). Its key component, the multi-deck Vibrating Screen, sorts particles through vibrating motion and specific mesh sizes. This ensures each product grade meets exact specifications while oversized material is automatically routed back to the correct crusher for re-processing, forming an efficient closed-circuit system that maximizes yield and product quality.

Types of CSTMG Screening Equipment

Stone Crushing Plant Material Handling

Stone crushing plant material processing involves systematically reducing raw feed like rocks and recycled concrete into specified aggregate sizes. This is achieved through a staged sequence of crushing, screening, and classification using specialized equipment. The core goal is to transform heterogeneous raw material into high-quality, graded final products such as base course, chips, and sand, essential for construction and industrial applications, while optimizing for efficiency, yield, and product shape.

Marble

Limestone

Granite

Basalt

Pebble

Quartz

CSTMG Crusher Plant Design and Installation Projects

Advantages

As an industry leader with 60+ patents and ISO 9001 certification, CSTMG combines cutting-edge engineering with decades of mining expertise to deliver superior coal crushing solutions.

CSTMG solutions are backed by comprehensive technical support and customizable wear protection packages tailored to each ore type’s abrasiveness and crushability. Our crushing circuits demonstrate exceptional reliability in processing iron, copper, gold, and polymetallic ores, consistently meeting stringent size reduction targets with minimal fines generation.

CSTMG Global Cases

Crushing and Screening Plant Works in Kenya

Aggregate Crusher Plant Operates in Serbia

Coal Crushing & Screening Plant in Indonesia

Stone Crushing Plant Application

CSTMG stone crushing plant is a complete set of equipment used to crush, screen, and shape bulk materials into finished products of varying particle sizes. Its crushing capacity covers a wide range of materials, from brittle to medium-hard to extra-hard, and is widely used in construction, infrastructure, mining, and chemical industries.

1. Core Materials for Construction and Infrastructure

These are the most common materials processed by stone crushing plants. After crushing, they are mainly used to produce concrete aggregates, subgrade fillers, and construction sand, with high requirements for the uniformity of the finished product particle size.

- Natural stone:

- Granite (Hardness: 6-7 Mohs; wear-resistant and pressure-resistant; crushed products are used for high-end building materials and paving stones).

- Limestone (Hardness: 3-5 Mohs; easy to crush; finished products are used as cement raw materials, concrete aggregates, and for lime production).

- Basalt (Hardness: 6-8 Mohs; extremely hard; crushed products are used for highway subgrades and high-strength concrete).

- Sandstone (Hardness: 3-6 Mohs; low water absorption; finished products are used for building decoration and lightweight aggregates).

- Tuff (Hardness: 3-4 Mohs; low density; crushed products are used for lightweight concrete and sound insulation materials).

- Recycled construction waste:

- Waste concrete blocks (After crushing, they can be recycled as reclaimed aggregates for road bases and non-load-bearing walls).

- Waste bricks/tiles (After crushing, they are used as subgrade fillers and for small prefabricated components).

- Demolition construction waste (Mixed materials need to be sorted and impurity-removed first, then the brick, stone, and concrete components are crushed).

2. Materials for Mining and Metallurgy

Most of these materials are medium-hard to extra-hard ores, requiring high-wear-resistant crushing equipment (e.g., jaw crushers, cone crushers). After crushing, they are used for metal mineral extraction or industrial raw material production.

- Metal ores:

- Iron ore (e.g., magnetite, hematite; Hardness: 5-6 Mohs; crushed before entering the beneficiation process for iron extraction).

- Copper ore (e.g., sulfide copper ore, oxide copper ore; Hardness: 4-6 Mohs; needs to be crushed to fine particle size to improve beneficiation efficiency).

- Gold ore (Associated with quartzite and sulfide ores; crushed before gold extraction via cyanidation or gravity separation).

- Bauxite (Hardness: 2-3 Mohs; prone to slime formation; humidity must be controlled during crushing; used for alumina production).

- Non-metallic ores:

- Quartz stone (Hardness: 7 Mohs; crushed products are used as glass raw materials, silica fume, and photovoltaic silicon materials).

- Fluorite (Hardness: 4 Mohs; high brittleness; crushed products are used as metallurgical fluxes and fluorochemical raw materials).

- Barite (Hardness: 3-3.5 Mohs; crushed products are used as drilling mud weighting agents and for barium salt production).

- Phosphate rock (Hardness: 3-5 Mohs; crushed products are used for phosphate fertilizer production; over-crushing must be avoided to prevent phosphorus loss).

3. Materials for Industrial and Special Fields

Crushing requirements for these materials are more targeted, and equipment materials or processes must be adjusted based on material properties (e.g., corrosiveness, viscosity, toxicity).

- Chemical and environmental protection materials:

- Gangue (Hardness: 2-4 Mohs; coal mine waste; crushed products are used for brick-making and as power generation fuel).

- Desulfurized gypsum (Power plant waste; low hardness and easy to agglomerate; needs to be disintegrated first before crushing; used for gypsum boards and cement retarders).

- Salt ore (Hardness: 2-3 Mohs; moisture-absorbent; stainless steel crushing equipment is required; used for salt production and chemical raw materials).

- Calcium carbide slag (Chemical waste residue; highly alkaline; crushed products are used for cement production and as desulfurizers).

- Other special materials:

- Refractory materials (e.g., high-alumina bricks, corundum; Hardness: 6-8 Mohs; crushed products are used for refractory product recycling).

- Ceramic waste (Hardness: 5-7 Mohs; crushed products are used for ceramic green bodies and permeable bricks).

- Glass waste (Hardness: 5.5 Mohs; high brittleness; crushed products are used for glass recycling and artificial stone).

4. Non-Crushable Materials or Those Requiring Special Treatment

It should be noted that a stone crushing plant is not universal. The following materials should be avoided for direct crushing, or require supporting pre-treatment equipment:

- Materials containing metal impurities (e.g., scrap steel, steel bars; must be separated by magnetic separators first, otherwise the crusher’s jaw plates will be damaged).

- High-viscosity materials (e.g., wet clay, sludge; prone to clogging the crushing chamber; need to be dried first or mixed with dry materials to reduce humidity).

- Flammable and explosive materials (e.g., coal lumps, sulfur; explosion-proof crushing equipment must be used to avoid friction-induced fires).

- Extra-large-sized materials (e.g., boulders with a diameter exceeding 1.5 meters; require multi-stage crushing via a “jaw crusher + impact crusher” combination, or supporting hydraulic hammers for pre-treatment).

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.