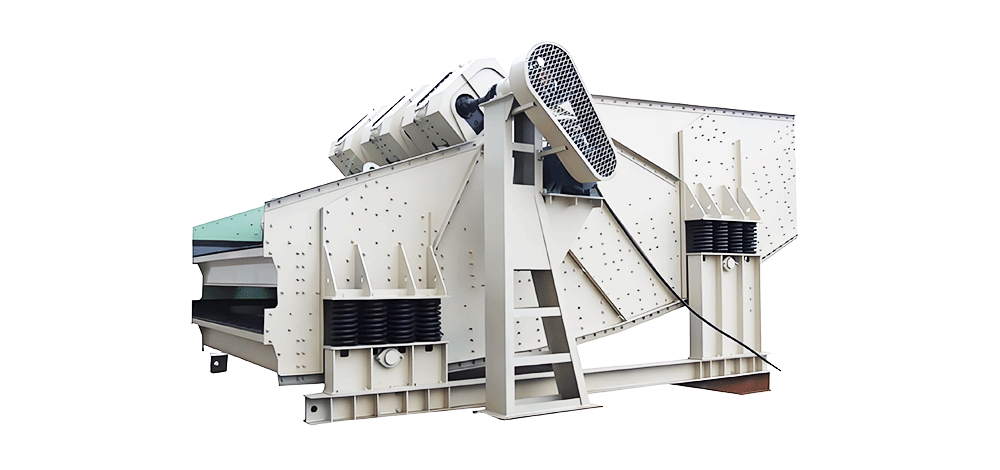

Roller Screen

CSTMG roller screen is a robust screening machine using rotating parallel shafts with interlocking discs to separate materials by size. Ideal for wet, sticky, or abrasive bulk materials (e.g., coal, ore), it offers high efficiency, low maintenance, and clog-free operation. Key advantages include durability, energy savings, and adaptability to harsh industrial environments.

APPLICATIONS

Coal

Mining

CSTMG Roller Screen Features

Wet Material Handling. Special disc spacing and rotation prevent clogging, efficiently screening coal, ore, and sticky materials (≤25% moisture) without downtime.

Smart Overload Protection. Auto-reverse function clears blockages, while torque sensors prevent motor damage from oversized feed.

Low Energy Use. 30-50% less power than vibrating screens, thanks to smooth rolling motion and optimized drive systems.

Modular Maintenance. Quick-release shafts and external bearings reduce downtime—replace parts in <1 hour.

Customizable Screening. Adjustable gaps and disc shapes for precise material classification.

CSTMG Roller Screen Specification

| Model | Capacity (t/h) | Screen Width (mm) | Qty of Roller Shaft (pcs) | Grading Size(mm) |

| CSTMG – GZS1410 | 400-900 | 1400 | 10 | 10-80 |

| CSTMG – GZS1612 | 500-1200 | 1600 | 12 | 10-80 |

| CSTMG – GZS1816 | 800-1600 | 1800 | 16 | 10-80 |

| CSTMG – GZS2016 | 1100-2000 | 2000 | 16 | 10-80 |

| CSTMG – GZS2424 | 1500-3000 | 2400 | 24 | 10-80 |

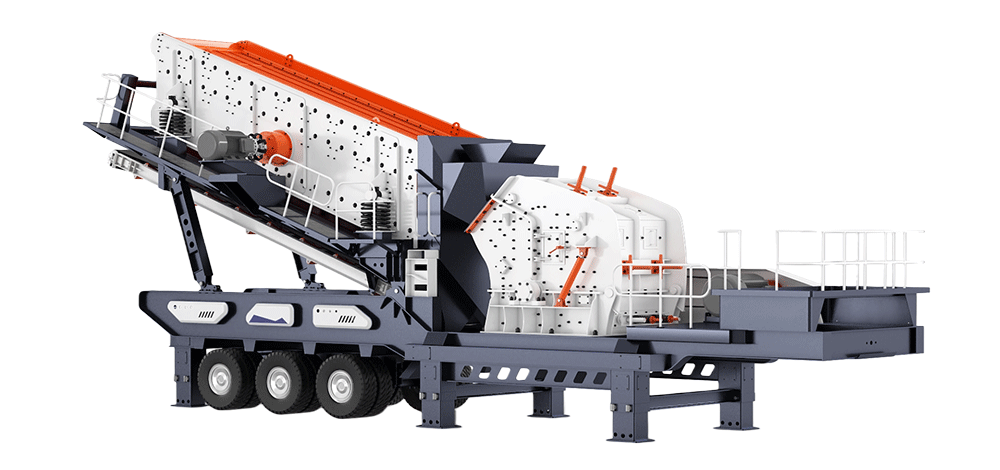

CSTMG Roller Screen Worldwide Cases

CSTMG Roller Screen Works in Malaysia

CSTMG Roller Screen Works in United Kingdom

CSTMG Roller Screen Test For Argentina Customer

Roller Screen Handling Materials

Coal & Carbon-Based Materials. Roller screens efficiently process raw coal, lignite, and coke, separating impurities with adjustable gaps.

Metallic Ores. Ideal for iron, copper, and manganese ores, roller screens classify abrasive materials before beneficiation.

Industrial Minerals. Screens limestone, gypsum, and phosphate rock with precision, optimizing particle size for cement, fertilizer, and construction use.

Recycling & Waste Materials. Handles construction debris, slag, and scrap metal, separating reusable materials. Robust construction resists impact damage, making it ideal for recycling plants and waste-to-energy facilities.

CSTMG Roller Screen Production Details

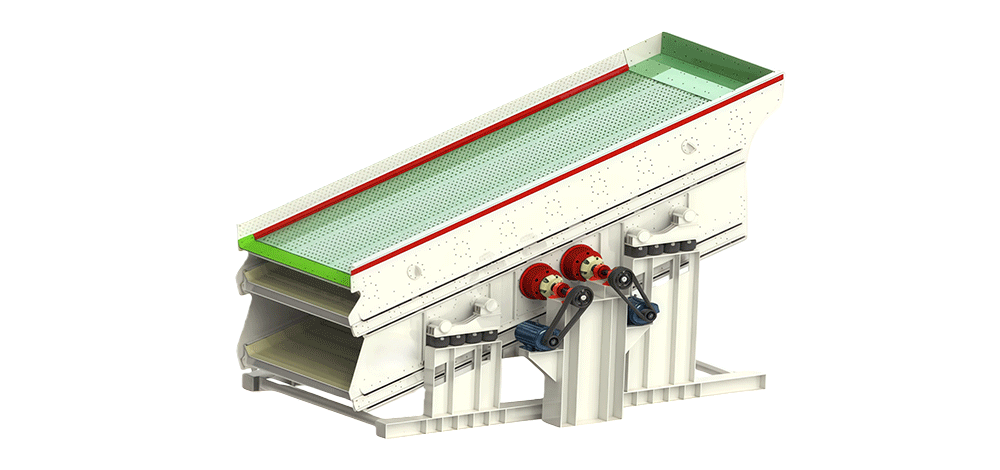

High Capacity Processing

- CSTMG roller screens boast large-scale processing capabilities. Their wide and long screen surfaces can handle massive materials. The rotation of rollers ensures uniform distribution and forward movement of materials, enabling continuous and efficient screening, meeting large-scale production needs.

Robust Structural Design

- With a sturdy frame and high – quality materials, they can withstand heavy material impacts and loads without easy deformation. Well – designed support and transmission systems ensure stable operation, low vibration, and reduced equipment failures.

Durable Components

- Rollers and sieve plates use wear-resistant materials like high-chromium cast iron. These offer good wear and corrosion resistance, long service life, reducing replacement frequency and maintenance costs.

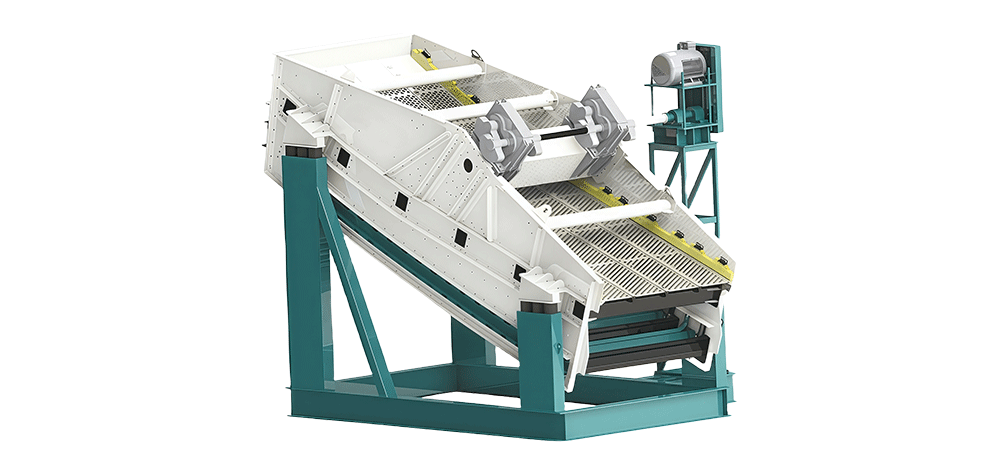

CSTMG Roller Screen Working Principle

The roller screen operates on a mechanical separation principle driven by rotating components. Its core structure consists of multiple parallel rollers arranged in a staggered or aligned configuration, each equipped with screening elements such as discs, bars, or spirals. When activated, the rollers rotate either in the same direction (synchronized) or opposite directions (counter-rotating) via a motor-driven transmission system.

Materials are fed onto the rotating roller bed from the inlet. As they move along the screening surface, smaller particles that meet the size requirement fall through the gaps between rollers or screening elements, collected as the undersize product. Larger particles, unable to pass through, continue moving along the roller axis and are discharged at the outlet as oversized material.

The rotational motion of the rollers serves multiple purposes: it facilitates material transportation, prevents clogging by agitating particles, and enhances screening efficiency through continuous tumbling. Adjustable parameters such as roller speed, gap width, and inclination angle allow customization for different material properties and processing requirements. This design ensures reliable, low-maintenance operation suitable for various industries, including mining, recycling, and agriculture.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.