Mobile Crushing Plant

The chassis, frames, and wear components of CSTMG mobile crushing plants are constructed using premium metallurgy and heavy-duty steel designed specifically to withstand the extreme vibration and stress of processing hard, abrasive rocks like granite and basalt.

Our mobile crushing plants cover wheeled (tire-mounted) and crawler (track-mounted) types, with customizable crushing hosts (jaw, impact, cone, hammer crushers) to match material hardness and output requirements.

Hot Sale Mobile Crusher Plant

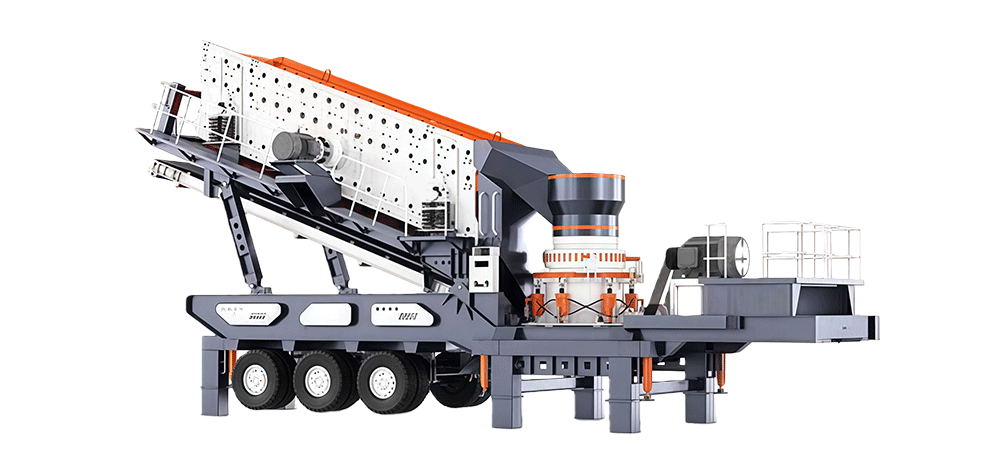

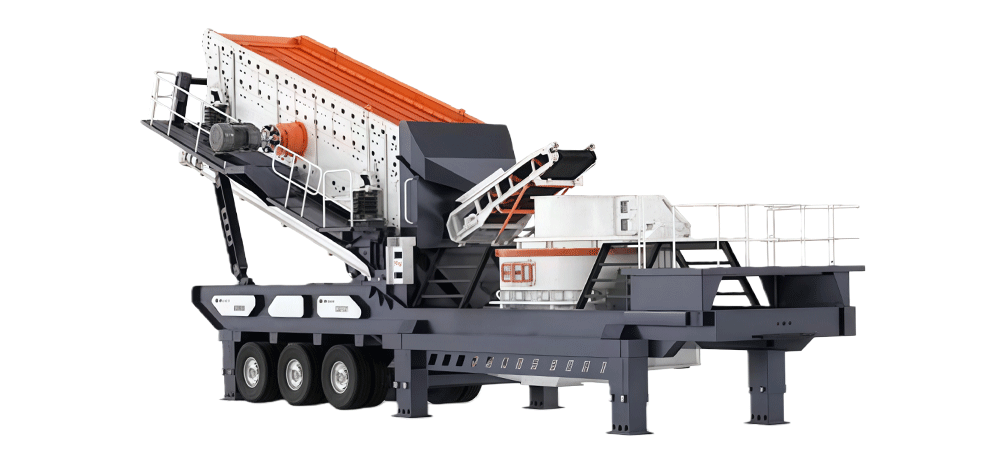

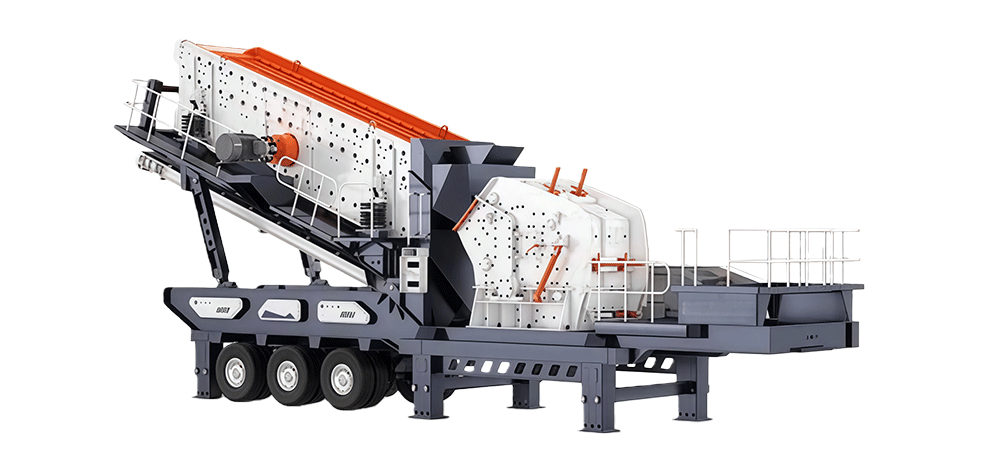

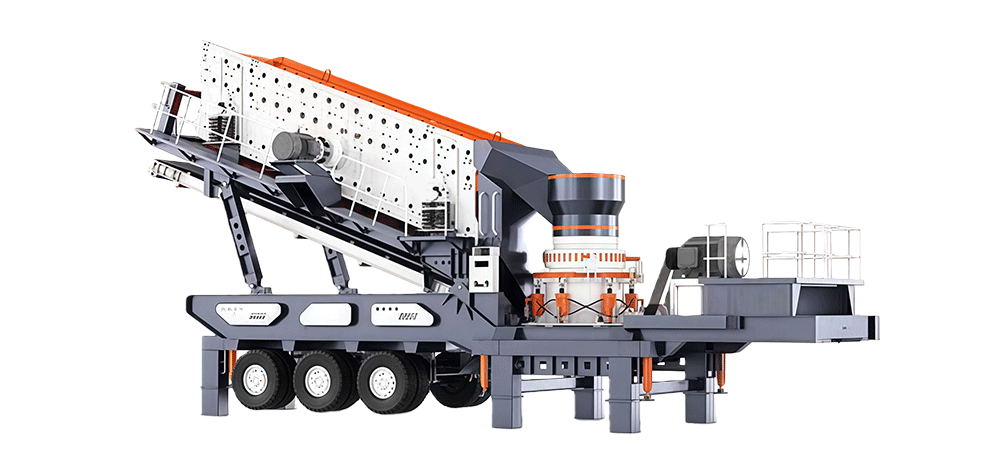

Wheeled Cone Crusher Plant

Transportation length (mm): 14,500-16,000

Transportation height (mm): 400-17,000

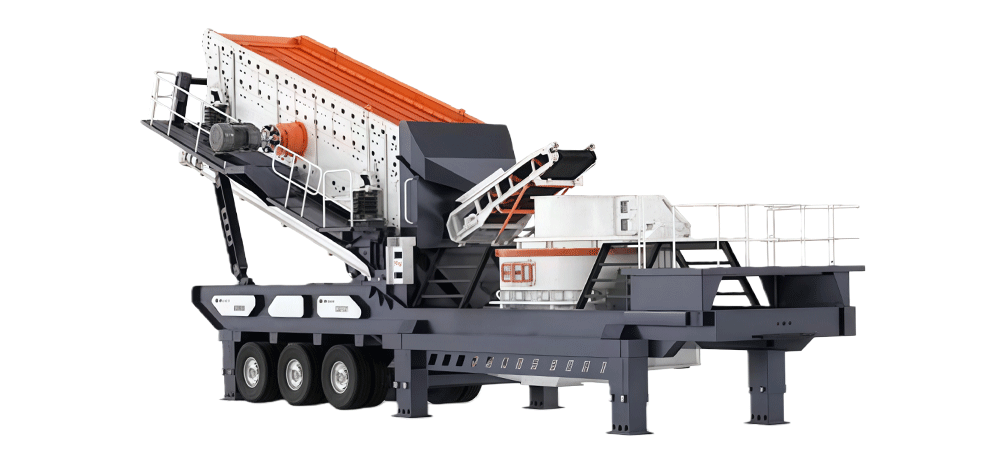

Wheeled Sand Making Plant

Transportation length (mm): 13,500-16,500

Transportation height (mm): 4,350-4,480

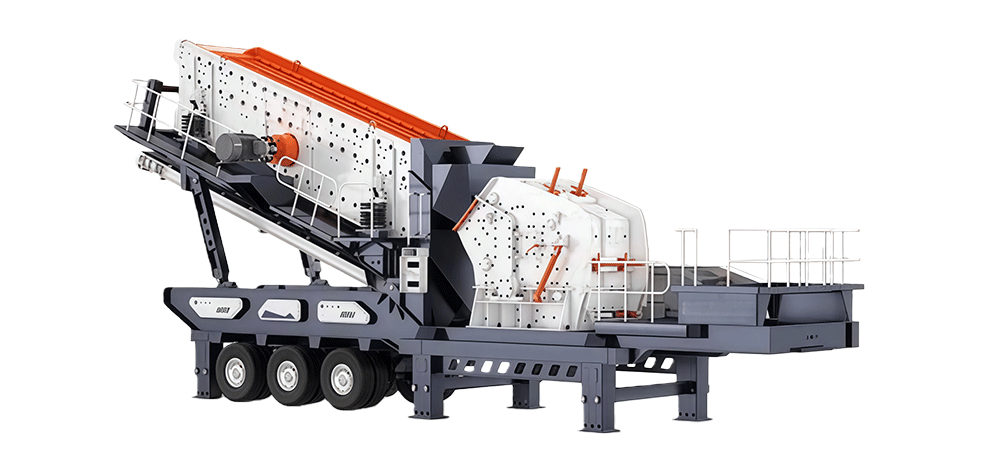

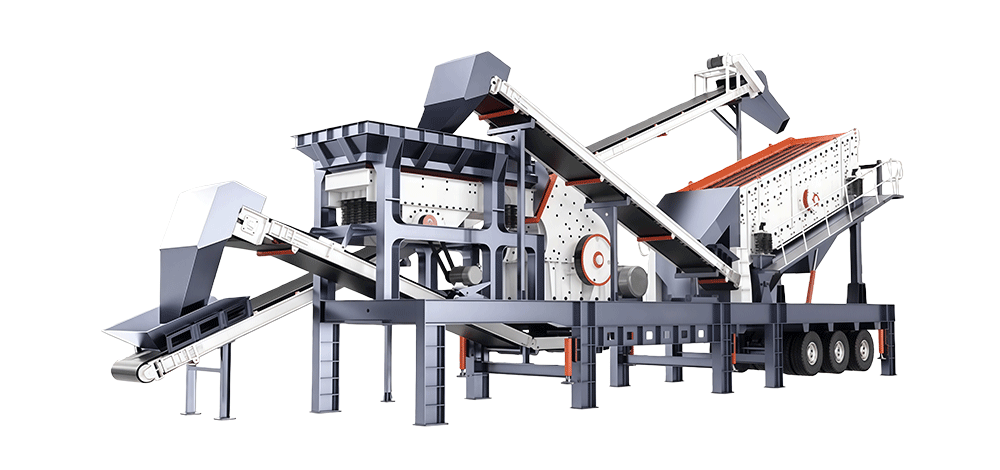

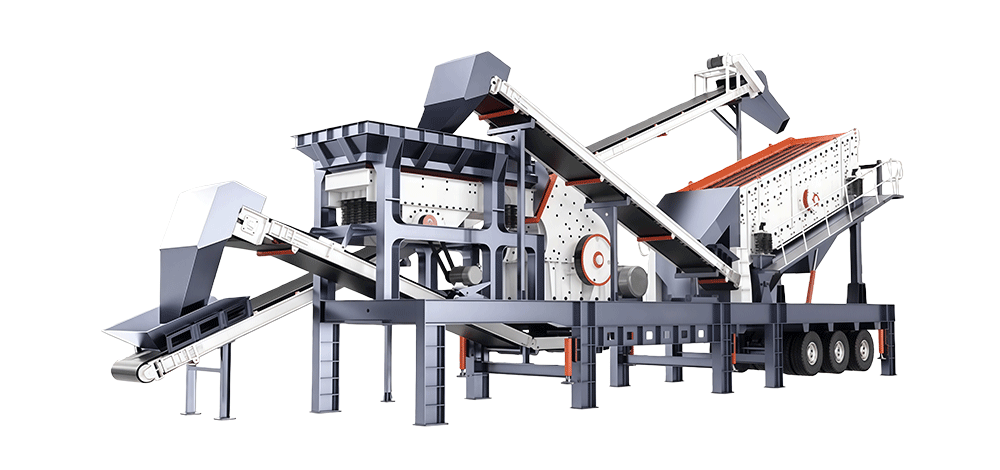

Wheeled Three Combination Mobile Crushing Plant

Capacity (t/h): 100-350

Feeding Size (mm): ≤700

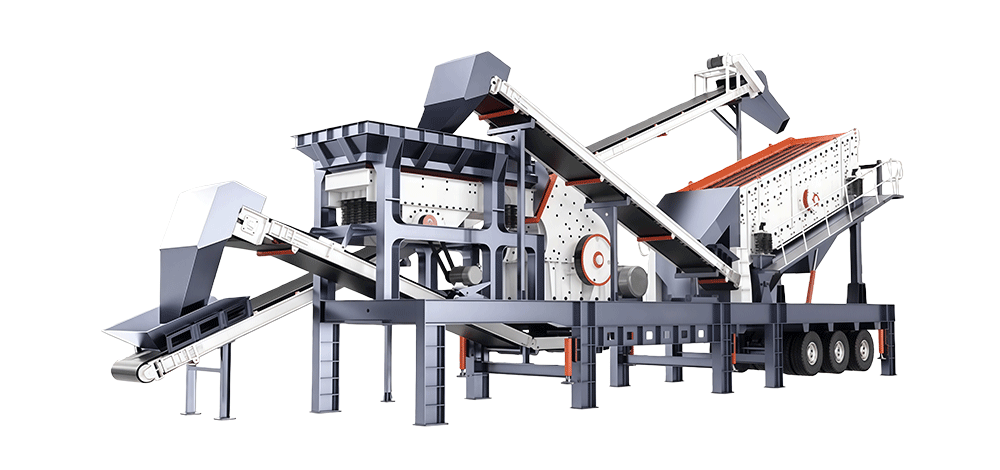

Wheeled Four Combination Mobile Crushing Plant

Capacity (t/h): 130-180

Feeding Size (mm): ≤500

Mobile Crawler Coarse Crusher Plant

Capacity (t/h): 100-580

Discharge opening (mm): 40-200

Mobile Crushing Plant Material Handling

Marble

Limestone

Granite

Basalt

Pebble

Quartz

Iron Ore

Copper Ore

Gold Ore

Lead-Zinc Ore

Molybdenum Ore

Nickel Ore

Mobile crushing stations are highly versatile and can process a wide range of materials of varying hardness, from soft to ultra-hard, including:

Ore and rock materials: Hard and abrasive rocks like granite, basalt, river pebbles, quartz stone; soft and medium-hard rocks like limestone, sandstone, dolomite, gypsum.

Industrial minerals: Iron ore, copper ore, gold ore, coal, coal and other metal/non-metal ores.

Natural aggregates: River sand, gravel, and mountain stones for producing graded sand and gravel aggregates.

Construction and demolition (C&D) waste: Concrete blocks, bricks, asphalt pavement, construction waste residues, and reinforced concrete (mobile crushers used here should be equipped with steel separation devices, like magnetic separators, to remove embedded steel bars).

Industrial solid waste: Steel slag, coal gangue, fly ash, slag, and chemical waste residues (with customized screening and impurity removal modules).

CSTMG Crusher Plant Design and Installation Projects

Why Choose CSTMG?

As an industry leader with 60+ patents and ISO 9001 certification, CSTMG combines cutting-edge engineering with decades of mining expertise to deliver superior coal crushing solutions.

CSTMG solutions are backed by comprehensive technical support and customizable wear protection packages tailored to each ore type’s abrasiveness and crushability. Our crushing circuits demonstrate exceptional reliability in processing iron, copper, gold, and polymetallic ores, consistently meeting stringent size reduction targets with minimal fines generation.

CSTMG Mobile Crushing Plant Global Cases

Mobile Crusher Plant Onsite Working in Ethiopia

Wheeled Crusher Plant in the Philippines

Mobile Combination Crushing Plant in Venezuela

Mobile Crusher Plant Advantages in Mining

Mobile crushing plants are the superior choices in the crushing and screening industry when your project is temporary, requires frequent moving, or is in a remote location. Here are the key advantages of a mobile crushing plant.

Exceptional Mobility and Site Flexibility

Unlike fixed crushing lines that require permanent foundation construction, mobile crushing plants (both tire-mounted and track-mounted types) can be moved directly to the material source.

Track-mounted models feature self-propelled hydraulic systems, enabling them to navigate rough terrains like mines, muddy construction sites, and mountainous areas, with the ability to climb slopes and turn in place.

Tire-mounted models can be towed by trucks for long-distance transportation between different construction sites. This eliminates the need for long-distance haulage of raw materials, saving significant transportation costs and time.

High Integration and Rapid Commissioning

These plants integrate feeding, crushing, screening, and conveying systems into a single compact unit. No on-site assembly is required, they can start operation immediately after being transported to the site and connected to power.

For large-scale projects, multiple mobile crushing plants can be flexibly combined into a complete production line, which can be disassembled and relocated in a short time, greatly shortening the project construction cycle.

Strong Adaptability to Diverse Materials

By replacing different types of crushing hosts (jaw crusher, impact crusher, cone crusher, hammer crusher, etc.) and adjusting screen mesh sizes, mobile crushing plants can handle a wide range of materials, including hard ores (granite, basalt), medium-hard rocks (limestone, river pebbles), construction and demolition (C&D) waste (concrete blocks, asphalt pavement), industrial solid waste (steel slag, coal gangue), and even biomass materials. This versatility makes them suitable for multiple application scenarios.

Cost Reduction and Efficiency Improvement

- Lower operating costs: On-site crushing reduces raw material transportation expenses by 30%–50% compared to hauling materials to a fixed crushing plant. Electric-powered models consume less energy than diesel-only equipment, cutting down energy costs significantly.

- High production efficiency: Equipped with intelligent load-adaptive control systems, these plants can automatically adjust the feeding speed based on the crusher’s load, avoiding overload or idling, and increasing overall production efficiency by 10%–15%.

- Reduced labor costs: Track-mounted models support remote control operation, allowing one operator to manage multiple devices, minimizing on-site personnel and lowering labor risks.

Superior Environmental Performance

Modern mobile crushing plants are designed with environmental protection in mind.

They can be equipped with integrated dust suppression systems (bag filters, spray dust collectors) and noise reduction enclosures, effectively controlling dust emissions (≤10mg/m³) and operating noise (≤75dB), meeting strict environmental standards for urban construction and mine operations.

For C&D waste treatment, optional steel separation and impurity removal modules can improve the purity of recycled aggregates, realizing the resource utilization of solid waste.

Reliable Performance in Special Scenarios

Customized mobile crushing plants can adapt to extreme working conditions.

For example, models with widened tracks are suitable for desert soft ground operations; low-temperature-resistant configurations can work in polar regions; dust-proof and explosion-proof designs are applicable to chemical waste treatment, expanding their application scope to special fields like emergency disaster relief and remote infrastructure construction.

Flexible Investment and Operation Modes

For users with limited capital, mobile crushing plants support flexible cooperation modes such as short-term leasing, financial leasing, and lease-purchase.

This reduces the initial investment threshold—leasing costs are only a fraction of the purchase price, making them ideal for temporary projects or small and medium-sized enterprises.

Major Types of CSTMG Mobile Crushing Plants

Mobile crushing plants are classified based on mobility mode, crushing function, and configuration structure, each tailored to specific materials, production scales, and working conditions. Below is a detailed breakdown of CSTMG mainstream types:

1. Classification by Mobility Mode

This is the most common classification method, which directly determines the adaptability of the equipment to the operation site.

Tire-Mounted/Wheeled-Mounted Mobile Crushing Plant

- Structural Features: Equipped with a heavy-duty truck tire chassis, no independent power system for movement, and requires a tractor for long-distance transportation. It is fixed by hydraulic outriggers during operation to ensure stability.

- Core Advantages: Low initial investment (20%–30% lower than track-mounted models compared under the same capacity), simple maintenance, fast long-distance transfer speed, and suitable for hard and flat roads.

- Applicable Scenarios: Urban construction waste recycling, plain sand and gravel yards, road reconstruction projects, and short-term small-to-medium-sized crushing tasks.

- Common Models: Tire-mounted jaw crushing plant (primary crushing), tire-mounted impact crushing plant and tire-mounted cone crusher plant (secondary crushing & shaping).

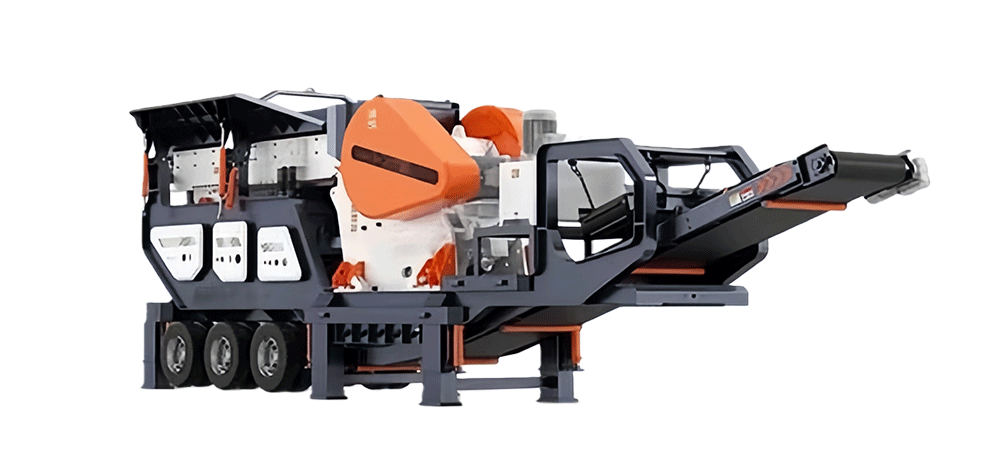

Tired-Mounted Impact Crusher Plant

Capacity (t/h): 70-380

Max feeding size (mm): 350-700

Tired-Mounted Cone Crusher Plant

Transportation length (mm): 14,500-16,000

Transportation height (mm): 400-17,000

Tired-Mounted Sand Making Plant

Transportation length (mm): 13,500-16,500

Transportation height (mm): 4,350-4,480

Tired-Mounted Three Combination Mobile Crushing Plant

Capacity (t/h): 100-350

Feeding Size (mm): ≤700

Tired-Mounted Four Combination Mobile Crushing Plant

Capacity (t/h): 130-180

Feeding Size (mm): ≤500

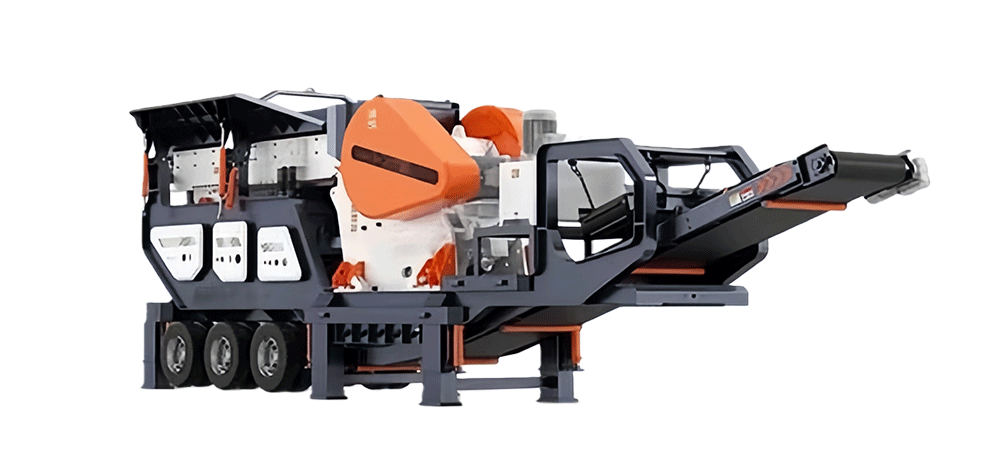

Track-Mounted/Crawler Mobile Crushing Plant

- Structural Features: Adopts a crawler chassis driven by a hydraulic system, with independent self-propulsion capability, and supports in-situ steering and slope climbing. Most models are equipped with oil-electric dual power systems.

- Core Advantages: Strong off-road and all terrain performance, can adapt to muddy, mountainous, and uneven mine sites, and also can climb slopes, move over mud, wetlands and rough mining terriain; supports remote control operation, high automation level; can do a spin turn, great for narrow spaces like tunnels or demolition sites; good stability without relying on external fixed facilities.

- Applicable Scenarios: Open-pit mine crushing, mountain water conservancy projects, remote area infrastructure construction, and complex terrain large-scale crushing tasks.

- Common Models: Track-mounted cone crushing plant (fine crushing of hard rocks), track-mounted combined crushing & screening plant (integrated primary-secondary crushing).

Track-Mounted Coarse Crusher Plant

Capacity (t/h): 100-580

Discharge opening (mm): 40-200

Track-Mounted Medium and Fine Crushing Plant

Capacity (t/h): 75-350

Mesh size (mm): 5-80

Classification by Crushing Function

Different crushing hosts are configured according to the material hardness and particle size requirements of finished products, which determines the processing capacity and application scope of the equipment.

Mobile Jaw Crushing Plant

- Core Host: Jaw crusher

- Crushing Characteristics: Large feed inlet, high crushing ratio, suitable for primary crushing of high-hardness materials; the finished product is mostly cubic particles, with uniform particle size.

- Processable Materials: Granite, basalt, iron ore, concrete blocks, and other hard and medium-hard materials.

- Typical Application: Primary crushing of raw ore in mines, initial crushing of construction waste, and coarse crushing of large stone materials.

Mobile Impact Crushing Plant

- Core Host: Impact crusher

- Crushing Characteristics: Uses impact force for crushing, good shaping effect of finished products, suitable for secondary crushing and shaping; low power consumption, and easy adjustment of discharge particle size.

- Processable Materials: Limestone, coal gangue, asphalt pavement, bricks, and other medium-hard and brittle materials.

- Typical Application: Production of high-grade aggregate for highway pavement, recycling of construction waste into recycled aggregate, and shaping of sand and gravel.

Mobile Cone Crushing Plant

- Core Host: Cone crusher (hydraulic cone crusher is mainstream)

- Crushing Characteristics: High crushing efficiency, stable operation, suitable for fine crushing of hard materials; strong wear resistance, and the finished product has low needle and flake content.

- Processable Materials: Granite, quartz stone, iron ore, and other high-hardness, high-abrasion materials.

- Typical Application: Fine crushing of metal ore in mines, production of high-strength concrete aggregate, and deep processing of hard rock.

Mobile Hammer Crushing Plant

- Core Host: Hammer crusher

- Crushing Characteristics: Simple structure, one-time crushing of large materials into small particles, suitable for crushing of brittle materials; low investment cost and easy maintenance.

- Processable Materials: Coal, limestone, gypsum, construction waste with low steel content, and biomass materials.

- Typical Application: Coal yard crushing, small-scale construction waste treatment, and processing of light industrial solid waste.

Mobile VSI Crusher

- Core Host: VSI crusher

- Crushing Characteristics: Turns small stones into sand (0-5mm) or shapes the stone to be perfectly round. Used for high-quality concrete production.

Mobile Screening Plant

- Core Host: Vibrating screen

- Crushing Characteristics: It works behind the crushers to separate the pile into different sizes (e.g., 0-5mm sand, 5-10mm gravel, 10-20mm stone).

Classification by Configuration Structure

According to whether the equipment integrates screening and conveying functions, it is divided into single-function and multi-function integrated types.

Standalone Mobile Crushing Plant

- Structural Features: Only integrates the feeding and crushing systems, without a built-in screening unit; the crushed materials need to be transported to a separate screening machine for grading.

- Core Advantages: Smaller volume, lighter weight, more flexible movement, and lower cost; can be flexibly matched with different screening equipment according to production needs.

- Applicable Scenarios: Supplementary crushing of existing production lines, temporary emergency crushing tasks, and small-scale processing projects.

Combined Mobile Crushing & Screening Plant

- Structural Features: Integrates feeding, crushing, screening, and conveying systems on a single chassis; the crushed materials are directly graded by the built-in vibrating screen to produce finished products of multiple specifications.

- Core Advantages: High integration, one-machine completion of the entire process; no need for on-site assembly, and can be put into operation immediately after being in place.

- Applicable Scenarios: Independent small-to-medium-sized crushing production lines, on-site processing of construction waste, and mobile sand and gravel yards in remote areas.

Modular Mobile Crushing Line

- Structural Features: Composed of multiple independent mobile crushing/screening modules (e.g., mobile jaw crushing module + mobile cone crushing module + mobile screening module); connected by belt conveyors to form a complete production line.

- Core Advantages: High production capacity (up to 800 t/h), flexible combination, and can be adjusted according to material types and finished product requirements.

- Applicable Scenarios: Large-scale mine crushing, large infrastructure projects, and centralized treatment of industrial solid waste.

Main Components of A Mobile Crushing Plant

A mobile crushing plant is an integrated piece of equipment that combines feeding, crushing, screening, conveying, and mobility systems. Each component works collaboratively to ensure efficient and stable on-site crushing operations. Below are its core components and their functions:

Mobility Chassis

The chassis is the foundation of the mobile crushing plant, determining its movement capability and operational stability. It is divided into two types based on mobility mode:

- Tire-mounted chassis: Equipped with heavy-duty truck tires and hydraulic outriggers. The outriggers extend to support the entire equipment during operation to prevent vibration-induced displacement; long-distance transportation requires a tractor for towing.

- Track-mounted chassis: Adopts a hydraulic-driven crawler system with independent propulsion, enabling in-situ steering, slope climbing (up to 30°–45°), and adaptation to muddy/mountainous terrain. High-end models are equipped with remote control systems for unmanned movement.

Feeding System

The feeding system is responsible for uniform and stable material delivery to the crushing chamber, avoiding overload or blockage of the crusher. Key components include:

- Vibrating feeder: The core device of the feeding system. It uses vibration to evenly transport raw materials (e.g., ore, construction waste) to the crusher inlet, and its adjustable feeding speed matches the crusher’s processing capacity.

- Feed hopper & grizzly bar: The feed hopper stores raw materials to ensure continuous feeding; the grizzly bar at the bottom pre-screens fine particles (e.g., soil, sand) in the raw material, preventing them from entering the crushing chamber and reducing unnecessary wear on the crusher.

Crushing System

This is the core part of the mobile crushing plant, which breaks large materials into small particles of the required size. The type of crusher is selected according to the material hardness and finished product requirements:

- Jaw crusher: For primary crushing of hard materials (granite, basalt, ore). Features a large feed inlet and high crushing ratio, suitable for coarse crushing of large raw materials.

- Impact crusher: For secondary crushing and shaping of medium-hard/brittle materials (limestone, concrete blocks, asphalt). Produces cubic finished particles with good shape, ideal for high-grade aggregate production.

- Cone crusher: For fine crushing of high-hardness, high-abrasion materials (iron ore, quartz stone). Has high crushing efficiency and low needle-flake content in finished products, suitable for deep processing of hard rocks.

- Hammer crusher: For one-step crushing of brittle materials (coal, gypsum, light industrial waste). Simple structure and low maintenance cost, suitable for small-scale processing tasks.

Screening System

The screening system classifies crushed materials into different particle size specifications to meet diverse application needs:

- Vibrating screen: The core screening device, usually designed as 2–4 layers of screens with different mesh sizes. It separates crushed materials into multiple finished product grades (e.g., 0–5 mm, 5–10 mm, 10–20 mm) through high-frequency vibration.

- Screen mesh: Replaceable components with different materials for different scenarios—high manganese steel mesh for hard rock crushing (wear-resistant) and polyurethane mesh for construction waste processing (low noise, light weight).

- Overflow & underflow outlets: Overflow (oversized particles) is returned to the crusher for re-crushing, while underflow (qualified particles) is transported to the finished product pile.

Conveying System

The conveying system connects all units to realize the transfer of raw materials, intermediate materials, and finished products. It consists of multiple belt conveyors with different functions:

- Feeding conveyor: Transports materials from the vibrating feeder to the crusher inlet.

- Discharge conveyor: Transports crushed materials from the crusher to the vibrating screen.

- Finished product conveyor: Transports screened qualified aggregates to the finished product stacking area; the return conveyor transports oversized particles back to the crusher for reprocessing.

- Magnetic Separator: A magnet suspended over the main belt to remove steel rebar (crucial for recycling).

- Key features: Adjustable conveying speed, equipped with side guards to prevent material spillage; some models use sealed conveyors to reduce dust emissions.

Power & Control System

This system provides energy and operational control for the entire equipment, ensuring safe and efficient operation:

- Power system:

- Electric type: Uses grid power for low energy consumption and noise, suitable for sites with stable power supply (urban construction waste plants, fixed gravel yards).

- Diesel type: Equipped with an on-board diesel generator for independent operation, suitable for remote mines or field construction sites without grid power.

- Oil-electric hybrid type: Supports switching between the two modes, with the highest flexibility (mostly used in track-mounted high-end models).

- Control system:

- PLC control cabinet: The core of the system, which realizes automatic control of the entire production line (e.g., load adaptive adjustment, fault alarm).

- Operation panel/remote controller: For manual operation or remote control (track-mounted models), allowing operators to adjust parameters or move the equipment from a safe distance.

- Fault diagnosis module: Monitors the temperature, pressure, and current of key components (bearings, hydraulic systems) in real time, and issues early warnings for abnormalities to reduce downtime.

Auxiliary Systems (Optional Configuration)

To meet environmental protection, safety, and special processing needs, mobile crushing plants can be equipped with the following auxiliary components:

- Dust suppression system: Bag dust collectors or spray dust collectors to control dust emissions, meeting strict environmental standards for urban operations.

- Noise reduction enclosure: Sound insulation panels installed around the crusher and motor to reduce operating noise to ≤75 dB, suitable for operations near residential areas.

- Steel separation device: Magnetic separators for separating steel bars from construction waste, improving the purity of recycled aggregates.

- Lubrication system: Automatic centralized lubrication device that regularly adds grease to bearings and gears to extend component service life.

Mobile Crushing Plant Common Configurations and Applications

Mobile crushing plants are configured with different combinations of feeding, crushing, screening, and conveying systems based on material types, finished product requirements, and application scenarios. Below are the most mainstream configurations, along with their structural features and typical uses:

Basic Configuration: Jaw Crusher + Vibrating Screen (Primary Crushing Line)

Configuration Composition

Tire-mounted/track-mounted chassis + Vibrating feeder + Jaw crusher + Single-deck vibrating screen + Belt conveyors + Electric/diesel power system

Core Features

- Focuses on coarse crushing; reduces large raw materials (≤800mm) to 50–150mm coarse aggregates.

- Simple structure, low failure rate, and easy maintenance; suitable for processing high-hardness materials.

- Oversized particles screened out are returned to the jaw crusher for re-crushing via a return conveyor.

Typical Applications

- Mine primary crushing: Crushes granite, basalt, iron ore raw stones into coarse ore for subsequent fine processing.

- Construction waste pre-treatment: Breaks large concrete blocks and bricks into small pieces for secondary crushing or direct backfilling.

- Remote area infrastructure: Processes mountain stones into coarse aggregates for rural road foundation construction.

Standard Configuration: Jaw Crusher + Impact Crusher + Multi-deck Vibrating Screen (Two-stage Crushing & Shaping Line)

Configuration Composition

Tire-mounted combined chassis (or two independent mobile stations) + Vibrating feeder + Jaw crusher (primary) + Impact crusher (secondary) + 3-deck vibrating screen + Multi-group belt conveyors + PLC control system

Core Features

- Achieves coarse crushing → fine crushing → shaping → grading in one continuous process; produces 2–3 grades of qualified aggregates (e.g., 0–5mm, 5–10mm, 10–20mm).

- The impact crusher optimizes the particle shape of finished products (cubic particles with low needle-flake content), meeting the requirements of high-grade highway pavement aggregates.

- High integration; no need for additional fixed equipment, and can be put into operation immediately after arriving at the site.

Typical Applications

- Sand and gravel aggregate production: Processes limestone, river pebbles into high-quality aggregates for commercial concrete mixing stations.

- Construction waste recycling: Turns demolished concrete and asphalt pavement into recycled aggregates for road surface paving and brick making.

- Road reconstruction projects: Crushes old asphalt pavement into graded recycled materials for new road base and surface layers.

Hard Rock Configuration: Jaw Crusher + Cone Crusher + Multi-deck Vibrating Screen (Hard Material Fine Crushing Line)

Configuration Composition

Track-mounted chassis (for complex terrain) + Vibrating feeder + Jaw crusher (primary) + Hydraulic cone crusher (secondary) + 4-deck vibrating screen + Oil-electric hybrid power system + Dust suppression system

Core Features

- Targets high-hardness, high-abrasion materials (granite, quartz stone, iron ore); the cone crusher has strong crushing capacity and long wear part life.

- Finished products have uniform particle size and stable quality, suitable for high-strength concrete and high-grade building stone production.

- Track-mounted chassis adapts to mine slopes and muddy sites; remote control operation ensures operator safety.

Typical Applications

- Open-pit mine fine crushing: Processes hard ore into qualified ore particles for mineral processing plants.

- High-grade aggregate production: Produces premium aggregates for high-rise building construction and bridge engineering.

- Industrial solid waste treatment: Crushes steel slag and water slag into aggregates for cement admixtures and road building materials.

Special Configuration: Hammer Crusher + Magnetic Separator (Solid Waste & Biomass Processing Line)

Configuration Composition

Tire-mounted chassis + Hopper feeder + Hammer crusher + Magnetic separator + 2-deck vibrating screen + Small diesel generator

Core Features

- One-step crushing: The hammer crusher directly crushes raw materials into small particles (≤20mm) without secondary processing, suitable for brittle materials.

- Equipped with a magnetic separator to separate iron impurities from materials; improves the purity of finished products.

- Compact structure, low investment cost, and easy mobility; ideal for small-scale processing tasks.

Typical Applications

- Industrial waste treatment: Crushes coal gangue, gypsum, and chemical waste residues into raw materials for brick making and fertilizer production.

- Biomass material processing: Processes coconut shells, wood chips, and straw into particles for biomass fuel production.

- Small-scale construction waste disposal: Handles decoration waste and small concrete blocks in urban communities.

Integrated Configuration: Combined Crushing & Screening Plant (All-in-one Mobile Line)

Configuration Composition

Track-mounted integrated chassis + Vibrating feeder + Jaw/impact/cone crusher (switchable host) + 3-deck vibrating screen + Belt conveyors + Remote control system + Dust & noise reduction system

Core Features

- All functions (feeding, crushing, screening, conveying) are integrated on a single chassis; no on-site assembly required, and can be started in 30 minutes after arriving at the site.

- The crushing host can be quickly replaced to adapt to different materials; supports load-adaptive intelligent control.

- High automation level; one operator can control the entire production line via remote control.

Typical Applications

- Emergency engineering: Rapidly processes earthquake/flood disaster ruins into aggregates for temporary road paving and foundation backfilling.

- Urban mobile processing: On-site treatment of construction waste in downtown areas to avoid material transportation and dust pollution.

- Rental projects: Flexible configuration switching to meet the diverse needs of short-term rental customers.

Environmental Protection Configuration: Crushing + Screening + Dust Suppression + Steel Separation (Green Recycling Line)

Configuration Composition

Tire-mounted chassis + Vibrating feeder + Impact crusher + 3-deck vibrating screen + Bag dust collector + Magnetic separator + Sealed belt conveyors + Noise reduction enclosure

Core Features

- Integrates dust control, metal separation, and noise reduction functions; meets strict environmental standards for urban operations (dust emission ≤10mg/m³, noise ≤75dB).

- The magnetic separator efficiently separates steel bars from construction waste, improving the purity of recycled aggregates to over 95%.

- Sealed conveyors prevent material spillage and dust leakage during transportation.

Typical Applications

- Urban construction waste recycling: Turns construction waste into high-quality recycled aggregates for recycled concrete and permeable bricks.

- Residential area nearby operations: Processes renovation waste without affecting the daily life of residents.

- Environmental protection projects: Meets the green production requirements of government-invested infrastructure projects.

Mobile Crushing Plant vs. Stationary/Fixed Crushing Plant

Mobile crushing plants and fixed crushing plants are two mainstream crushing solutions, with core differences in mobility, investment cost, production scale, and application scenarios.

Below is a detailed comparison:

| Comparison Dimension | Mobile Crushing Plant | Stationary/Fixed Crushing Plant |

|---|---|---|

| Core Design Concept | Integrated, movable unit; can be directly transported to the material source for on-site processing | Fixed production line; requires permanent civil foundation construction; materials must be transported to the plant for processing |

| Mobility & Site Requirements | 1. Two types: tire-mounted (towed by tractor, for flat/hard roads) and track-mounted (self-propelled, adapts to mountains/muddy terrain) 2. No need for civil foundation; hydraulic outriggers or crawler chassis ensure stability during operation 3. Fast relocation: tire-mounted can be transferred in hours, track-mounted can move short distances on-site in minutes | 1. Immovable; fixed installation on reinforced concrete foundation 2. Requires flat, hardened site with sufficient space for arranging feeding, crushing, screening, and storage areas 3. Relocation is impossible; dismantling and reinstallation are costly and time-consuming |

| Investment Cost | 1. Higher initial unit investment: Track-mounted models cost 2–3 times more than equivalent stationary crushers; tire-mounted models are 30%–50% more expensive than stationary ones 2. Low auxiliary cost: No civil engineering or foundation construction required 3. Flexible investment: Supports leasing, financing, or lease-purchase modes | 1. Lower initial unit investment: Simple structure, mature technology, and lower manufacturing cost 2. High auxiliary cost: Requires large sums for civil foundation, factory building, and supporting facilities (e.g., power supply, water supply) 3. High upfront capital threshold; suitable for long-term fixed projects |

| Production Capacity & Efficiency | 1. Medium to small-scale output: Most models have a capacity of 30–500 t/h; integrated design limits the size of the crushing host 2. Slightly lower efficiency: Frequent relocation may cause temporary downtime; small equipment size leads to lower single-machine throughput | 1. Large-scale, high-efficiency output: Capacity can reach 100–2000 t/h; large crushing hosts and optimized production line layout maximize processing efficiency 2. Stable operation: No relocation interference; continuous production with 24-hour operation capability |

| Material Transportation Cost | Extremely low: On-site crushing eliminates the need to transport large raw materials, reducing transportation costs by 30%–60% (especially for bulky materials like construction waste and ore)Applicable to scattered material sources | High: Raw materials must be transported from mining/construction sites to the fixed plant via trucks; long-distance transportation increases costs and material lossOnly cost-effective when material sources are concentrated |

| Adaptability to Materials & Products | 1. High flexibility: The crushing host (jaw/impact/cone crusher) can be quickly replaced to handle hard ores, construction waste, industrial slag, etc. 2. Adjustable screen mesh size for on-demand production of different particle size aggregates; suitable for small-batch, multi-specification orders | 1. Strong specialization: Designed for specific materials (e.g., limestone, granite) with fixed crushing processes; not easy to modify 2. Stable product quality: Optimized production line ensures uniform particle size and shape; suitable for large-batch, standardized aggregate supply |

| Operational & Maintenance Cost | 1. Higher maintenance cost: Complex structure (hydraulic system, chassis, remote control system) leads to more wear parts and higher maintenance difficulty 2. Lower labor cost: Track-mounted models support remote control; 1–2 operators can manage the entire unit 3. Energy consumption: Slightly higher than stationary plants due to integrated power systems | 1. Lower maintenance cost: Simple structure, mature technology, easy access to spare parts, and lower maintenance frequency 2. Higher labor cost: Requires more operators for feeding, monitoring, and equipment management 3. Energy consumption: Lower unit energy consumption due to grid power supply and optimized process matching |

| Environmental Performance | 1. Low on-site pollution: On-site processing reduces material transportation dust; optional integrated dust suppression and noise reduction systems meet urban operation standards 2. Suitable for green projects: Realizes “zero transportation” of construction waste and on-site resource reuse | 1. Concentrated pollution: Requires centralized dust collection, sewage treatment, and noise reduction facilities to meet environmental standards 2. High environmental investment: Needs to build dedicated dust removal systems and waste storage yards; strict compliance with environmental assessment requirements |

| Typical Application Scenarios | 1. Construction waste recycling (urban demolition sites) 2. Open-pit mines with scattered ore bodies (remote mountainous areas) 3. Temporary infrastructure projects (highway/railway reconstruction, disaster relief) 4. Small-to-medium-sized aggregate production with frequent relocation needs | 1. Large-scale stone quarries with concentrated material sources (plain areas) 2. Fixed sand and gravel production bases for commercial concrete mixing stations 3. Long-term industrial solid waste treatment projects (e.g., steel slag processing plants) 4. High-demand, standardized aggregate supply for large construction projects |

Key Selection Guidelines

Choose mobile crushing plant if:

- Your material source is scattered (e.g., multiple demolition sites, dispersed ore bodies) or requires on-site processing.

- The project is short-term (≤2 years) or temporary (e.g., emergency disaster relief, road maintenance).

- You need to reduce raw material transportation costs (critical for bulky materials like concrete blocks and large ore).

- The operation site is complex (mountains, wetlands) and cannot support civil foundation construction.

Choose stationary/fixed crushing plant if:

- Your material source is stable and concentrated (e.g., a large quarry with 5+ years of mining life).

- You require large-scale, continuous production (capacity ≥500 t/h) to supply standardized aggregates.

- You have sufficient upfront capital for civil engineering and supporting facilities.

- The project is long-term (≥3 years) with fixed production locations and stable market demand.

Complementary Application Scenarios

In some large-scale projects, the two types can be combined for optimal efficiency:

- Use track-mounted mobile crushing plants for on-site coarse crushing of raw ore in remote mines, then transport the crushed coarse aggregates to a stationary fine crushing line for deep processing to produce high-quality finished aggregates.

- Use mobile crushing plants for on-site treatment of construction waste in urban areas, then transport the recycled aggregates to a fixed production line for shaping and grading to meet high-standard construction needs.

Wheeled Type Crushing Plant vs. Crawler Type Crushing Plant

Wheeled (tire-mounted) and crawler (track-mounted) crushing plants are the two main mobile solutions, differing fundamentally in mobility mode, terrain adaptability, cost, and application scenarios. Your choice hinges on job site conditions, relocation needs, and budget constraints.

Below is a detailed comparison and selection framework.

| Comparison Dimension | Wheeled Type Crushing Plant | Crawler Type Crushing Plant |

|---|---|---|

| Mobility & Movement | 1. Trailer-mounted; relies on a tractor for long-distance transport (compliant with road regulations) 2. Fast highway relocation (≤80 km/h) with no need for disassembly; short on-site repositioning via hydraulic outriggers 3. Best for paved/hard-packed flat terrain; limited to ≤15° slopes | 1. Self-propelled via hydraulic crawler chassis; short on-site movement in minutes, long-distance transport requires a low-loader truck 2. Superior off-road capability: climbs 30°–45° slopes, navigates mud, rocks, wetlands, and uneven ground 3. Low ground pressure (0.1–0.3 MPa) prevents sinking in soft soil; no road damage during on-site movement |

| Setup & Site Prep | 1. Quick deployment: hydraulic outriggers for leveling; operational in 30–60 minutes after arrival 2. No civil foundation needed; works on compacted ground or concrete pads 3. Modular design allows easy combination with other wheeled units (e.g., jaw + impact + screen) | 1. One-key start/stop; self-leveling hydraulic system enables operation on uneven terrain in 20–40 minutes 2. Ultra-low site prep: works directly on soil, gravel, or mine benches without ground hardening 3. Integrated chassis: all functions (feeding, crushing, screening, conveying) on one unit for “plug-and-crush” operation |

| Investment & Operating Costs | 1. Lower initial investment: 30%–50% cheaper than equivalent crawler models 2. Lower maintenance: simpler chassis (no hydraulic track drive); tires are easy to replace 3. Lower energy consumption: optimized for road transport and stable flat-site operation | 1. Higher upfront cost: Track-mounted units cost 2x more than wheeled 2. Higher maintenance: complex hydraulic track systems and sealed components require specialized service 3. Slightly higher fuel consumption due to heavy chassis and continuous hydraulic operation |

| Production & Flexibility | 1. Capacity: 50–300 t/h; suitable for medium-scale, standardized aggregate production 2. Easy to switch crushing hosts (jaw/impact/cone) for different materials (limestone, construction waste) 3. Ideal for multi-site projects with frequent long-distance relocation | 1. Capacity: 60–500 t/h; handles high-hardness materials (granite, basalt) with stable throughput 2. Modular crushing units (switchable jaw/impact/cone) adapt to variable material sources 3. Perfect for on-site follow-up to mining faces or demolition areas; reduces material transport by 40%–60% |

| Environmental & Safety | 1. Low noise/dust: integrated dust suppression and noise reduction; compliant with urban operation standards 2. Safe for road transport: meets traffic regulations; no special permits needed for towing | 1. Sealed hydraulic systems and low-emission engines minimize on-site pollution 2. Remote control operation (1–2 operators) keeps personnel away from dangerous areas (e.g., mine slopes) 3. Emergency stop and overload protection prevent accidents in harsh conditions |

| Typical Applications | 1. Urban construction waste recycling (demolition sites, flat industrial zones) 2. Road/railway infrastructure (paved terrain, frequent relocation between sections) 3. Commercial aggregate production (quarries with fixed access roads) 4. Small-scale industrial waste treatment (coal gangue, gypsum) | 1. Open-pit mining (remote mountains, scattered ore bodies, steep slopes) 2. Large-scale construction waste in mountainous areas (earthquakes/floods with no road access) 3. Wetland/landfill waste processing (soft ground requiring low ground pressure) 4. Military/emergency engineering (rapid on-site material processing) |

Core Selection Rules

Choose wheeled type crusher plant if:

- Job sites are flat with paved roads and frequent long-distance relocation (e.g., urban construction waste, highway projects).

- You have a limited budget but need medium-scale production (≤300 t/h) and easy maintenance.

- The project is short-term (≤2 years) with multiple scattered sites requiring quick transfer.

Choose crawler type crusher plant if:

- Terrain is complex (mountains, mud, slopes ≥20°) or remote with no paved access (e.g., open-pit mines, disaster zones).

- You need to follow material sources (e.g., mining face advancement, on-site construction waste treatment).

- Long-term (≥3 years) harsh-environment operation demands stability and low ground pressure.

Balancing Costs and Performance in Mobile Crushing Plant

To achieve a balance between costs and performance when selecting and operating mobile crushing plants, it is crucial to focus on core factors such as wear part consumption, production line matching, process design, material pre-treatment, special material handling, and environmental compliance.

Below is a detailed analysis based on practical application scenarios:

1. Rationalize Wear Part Costs Based on Material Hardness

Wear parts (e.g., blow bars, liners, jaw plates) are the primary ongoing cost driver for mobile crushing plants, and their service life varies drastically with material hardness—often by a factor of several between hard materials (e.g., granite) and soft materials (e.g., limestone).

Neglecting this difference can lead to excessive maintenance costs that erode profits.

- Cost-Benefit Calculation Pre-Purchase: Before investing, conduct a detailed analysis of the target material’s hardness and abrasiveness. For hard materials like granite, prioritize equipment with wear-resistant components (e.g., high-manganese steel or composite alloy parts) even if the initial investment is higher; for soft materials like limestone, standard wear parts can balance cost and performance.

- Preventive Maintenance: Establish a replacement schedule for wear parts based on production volume (e.g., jaw plates typically last 800–1200 hours for hard materials) and stock 1–2 sets of spare parts to avoid unplanned downtime, which is more costly than proactive replacement.

2. Avoid Production Line Bottlenecks Through Capacity Matching

Many new users improperly match two mobile stations (one for primary crushing, one for secondary crushing), resulting in mismatched capacities—either the primary crusher processes material too quickly for the secondary crusher to handle, or vice versa. This leads to severe efficiency waste and increased costs.

- Capacity Alignment Principle: Ensure the secondary crusher’s throughput matches or slightly exceeds the primary crusher’s output. For example, if a jaw crusher (primary) has a capacity of 200 t/h, select an impact or cone crusher (secondary) with a capacity of 200–250 t/h.

- Modular Configuration: Choose mobile stations with adjustable speed settings for feeding and conveying systems. This flexibility allows on-site fine-tuning to eliminate bottlenecks as material properties or production demands change.

3. Adopt Closed Circuit Systems to Guarantee Product Quality and Reduce Hidden Costs

Novice users often overlook the importance of a Closed Circuit system, assuming the plant simply converts raw stone into crushed material. In reality, a closed circuit—equipped with a return conveyor—is critical for ensuring product quality and avoiding additional costs.

- Working Principle: After crushing, materials are screened; qualified products (meeting particle size requirements) are discharged, while oversized particles are transported back to the crusher via the return conveyor for reprocessing.

- Cost-Saving Value: Without a closed circuit (open-circuit crushing), the output will contain excessive oversized particles, leading to customer rejection. Retrofitting a separate screener or reprocessing the material will significantly increase costs. Investing in a closed circuit system upfront ensures consistent product quality and eliminates these hidden expenses.

4. Utilize Scalping (Pre-Screening) to Enhance Efficiency and Reduce Wear

Scalping, removing fine particles (e.g., soil) from raw materials before they enter the crusher, is a cost-effective step that many users ignore.

Raw materials like mountain stones or construction waste often contain large amounts of soil, which can severely impact operations if not pre-screened.

- Risks of Skipping Scalping: Soil entering the crusher accelerates wear on parts, clogs the crushing chamber during rainy weather (causing downtime), and reduces the final product’s quality (high soil content lowers market value).

- Economic Benefits: Equipping the feeder with grizzly bars or a pre-screening module removes soil and fine particles in advance, increasing production capacity by 20% and extending wear part life by 30%. This small upfront investment yields significant long-term savings.

5. Address Steel Bar Hazards in Construction Waste to Protect Conveyor Belts

When processing construction waste, steel bars (not hard concrete) are the biggest threat to equipment, especially conveyor belts.

While most mobile plants are equipped with magnetic separators to remove steel, excessively long steel bars (e.g., over 1 meter) can get stuck in gaps between the conveyor and frame, tearing the expensive belt instantly.

- Preventive Measures: Do not rely solely on automatic magnetic separation. Install manual sorting stations or hydraulic shears at the feed inlet to cut long steel bars before they enter the system. This reduces belt damage, avoids costly belt replacements, and minimizes unplanned downtime.

6. Prioritize Environmental Compliance to Avoid Operational Shutdowns

In 2025, many mobile crushing plants are shut down not due to mechanical failure, but due to non-compliance with dust and noise regulations. Environmental compliance is a “life-or-death line” for sustainable operations.

- Dust Control: Unlike fixed plants with enclosed workshops, mobile units require targeted dust suppression measures. Equip key dust-generating points (feed inlet, discharge outlet) with high-pressure spray systems or dust-proof curtains. For strict environments, opt for bag filters to ensure dust emissions ≤10 mg/m³.

- Noise Reduction: Crushers generate high noise levels. When operating near residential areas, install sound insulation enclosures around the crusher and motor, or use noise-canceling buffers to keep noise ≤75 dB. This avoids public complaints and potential project halts.

Core Principles for Balancing Cost and Performance

- Match Equipment to Material: Select wear parts and crusher types based on material hardness to optimize maintenance costs.

- Ensure Capacity Alignment: Avoid bottlenecks by matching primary and secondary crusher throughputs.

- Invest in Key Processes: Prioritize closed circuit and pre-screening systems to guarantee quality and reduce hidden costs.

- Mitigate Special Risks: Address steel bar hazards in construction waste to protect high-value components like conveyor belts.

- Comply with Environmental Standards: Proactively invest in dust and noise control to avoid shutdowns and legal risks.

By integrating these factors into the selection and operational process, users can maximize production efficiency, minimize unnecessary costs, and achieve a sustainable balance between investment returns and long-term performance.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.