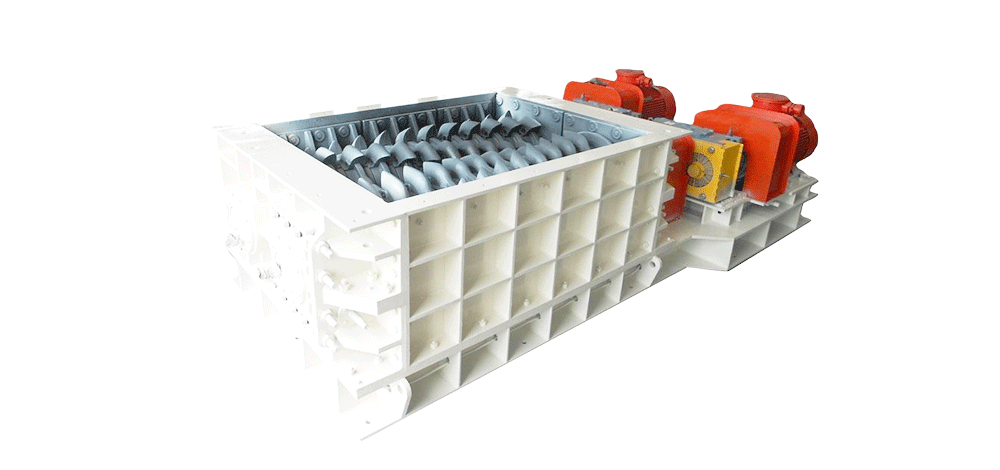

Mineral Sizer

CSTMG’s Mineral Sizer is a high-efficiency crushing solution for coal, soft ores, and abrasive materials. Featuring dual rotating shafts with intermeshing teeth, it delivers precise sizing with minimal fines. The robust design handles wet, sticky feeds without clogging while reducing energy consumption by 30-50% compared to traditional crushers. Ideal for mining, recycling, and mineral processing applications requiring high capacity and low maintenance.

APPLICATIONS

Coal

Mining

CSTMG Mineral Sizer Features

Wide Material Adaptability. Equipped with interchangeable teeth (straight/spiral/wolf-tooth) for coal, limestone, and gangue. Handles materials up to 150MPa hardness and 25% moisture, excelling in brittle/soft ore crushing.

Precise Size Control. Adjustable roller gaps (10-200mm) ensure uniform output with ≤5% over-crushing. Ideal for strict sizing requirements in coal washing or aggregate production.

Multi-Layer Overload Protection. Hydraulic coupling + shear-pin coupling + electrical interlock prevents motor damage from oversized materials or tramp iron, reducing downtime by 70%.

Robust & Compact Design. Tungsten carbide teeth (HRC≥65) withstand abrasion for 30,000+ hours. Modular structure allows on-site tooth replacement in 2 hours, cutting maintenance costs by 50%.

CSTMG Mineral Sizer Specification

| Primary Mineral Sizer | ||||

| 150 Series Primary Mineral Sizer | ||||

| Model | CSTMG – 2PLF-150/250 | CSTMG – 2PLF-150/300 | CSTMG – 2PLF-150/350 | CSTMG – 2PLF-150/400 |

| Roller Diameter(mm) | 1500 | 1500 | 1500 | 1500 |

| Roller Length(mm) | 2500 | 3000 | 3500 | 4000 |

| Input Size(mm) | ≤1500 | ≤1500 | ≤1500 | ≤1500 |

| Output Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 |

| Capacity(t/h) | ≤4500 | ≤5500 | ≤6500 | ≤7500 |

| 140 Series Primary Mineral Sizer | ||||

| Model | CSTMG – 2PLF-140/200 | CSTMG – 2PLF-140/250 | CSTMG – 2PLF-140/300 | CSTMG – 2PLF-140/350 |

| Roller Diameter(mm) | 1400 | 1400 | 1400 | 1400 |

| Roller Length(mm) | 2000 | 2500 | 3000 | 3500 |

| Input Size(mm) | ≤1400 | ≤1400 | ≤1400 | ≤1400 |

| Output Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 |

| Capacity(t/h) | ≤3000 | ≤4000 | ≤5000 | ≤6000 |

| 120 Series Primary Mineral Sizer | ||||

| Model | CSTMG – 2PLF-120/150 | CSTMG – 2PLF-120/200 | CSTMG – 2PLF-120/250 | CSTMG – 2PLF-120/300 |

| Roller Diameter(mm) | 1200 | 1200 | 1200 | 1200 |

| Roller Length(mm) | 1500 | 2000 | 2500 | 3000 |

| Input Size(mm) | ≤1200 | ≤1200 | ≤1200 | ≤1200 |

| Output Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 |

| Capacity(t/h) | ≤1500 | ≤2000 | ≤2500 | ≤3000 |

| 100 Series Primary Mineral Sizer | ||||

| Model | CSTMG – 2PLF-100/120 | CSTMG – 2PLF-100/150 | CSTMG – 2PLF-100/200 | CSTMG – 2PLF-100/250 |

| Roller Diameter(mm) | 1000 | 1000 | 1000 | 1000 |

| Roller Length(mm) | 1200 | 1500 | 2000 | 2500 |

| Input Size(mm) | ≤1000 | ≤1000 | ≤1000 | ≤1000 |

| Output Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 |

| Capacity(t/h) | ≤800 | ≤1200 | ≤1500 | ≤2000 |

| Secondary Mineral Sizer | ||||||||||

| 100 Series Secondary Mineral Sizer | ||||||||||

| Model | CSTMG – 2PLF-100/150 | CSTMG – 2PLF-100/200 | CSTMG – 2PLF-100/250 | CSTMG – 2PLF-100/300 | CSTMG – 2PLF100/350 | |||||

| Roller Diameter(mm) | 1000 | 1000 | 1000 | 1000 | 1000 | |||||

| Roller Length(mm) | 1500 | 2000 | 2500 | 3000 | 3500 | |||||

| Input Size(mm) | ≤400 | ≤400 | ≤400 | ≤400 | ≤400 | |||||

| Output Size(mm) | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 | |||||

| Capacity(t/h) | 400-800 | 500-1000 | 650-1200 | 800-1500 | 1000-1800 | |||||

| 80 Series Secondary Mineral Sizer | ||||||||||

| Model | CSTMG – 2PLF-80/150 | CSTMG – 2PLF-80/200 | CSTMG – 2PLF-80/250 | CSTMG – 2PLF-80/300 | ||||||

| Roller Diameter(mm) | 800 | 800 | 800 | 800 | ||||||

| Roller Length(mm) | 1500 | 2000 | 2500 | 3000 | ||||||

| Input Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 | ||||||

| Output Size(mm) | 50-150 | 50-150 | 50-150 | 50-150 | ||||||

| Capacity(t/h) | 300-500 | 400-800 | 500-1200 | 600-1500 | ||||||

| 60 Series Secondary Mineral Sizer | ||||||||||

| Model | CSTMG – 2PLF-60/120 | CSTMG – 2PLF-60/160 | CSTMG – 2PLF-60/200 | |||||||

| Roller Diameter(mm) | 600 | 600 | 600 | |||||||

| Roller Length(mm) | 1200 | 1600 | 2000 | |||||||

| Input Size(mm) | ≤300 | ≤300 | ≤300 | |||||||

| Output Size(mm) | 50-150 | 50-150 | 50-150 | |||||||

| Capacity(t/h) | 200-400 | 250-600 | 300-800 | |||||||

CSTMG Mineral Sizer Worldwide Cases

CSTMG Mineral Sizer Works in Algeria

CSTMG Mineral Sizer Installs in Peru

CSTMG Mineral Sizer Works in United Kingdom

Mineral Sizer Handling Materials

High-Moisture & Sticky Materials. Handles wet coal, clay-rich ores, and sticky minerals (up to 25% moisture) without clogging, thanks to self-cleaning tooth design and non-clogging gaps.

Abrasive & Hard Ores. Crushes iron ore, quartzite, and slag (hardness ≤ 150MPa) with tungsten carbide teeth (HRC≥65), offering 3x longer wear life than standard crushers.

Friable & Brittle Minerals. Minimizes over-crushing (fines generation <5%) for salt, oil shale, and limestone, preserving lump product quality for downstream processing.

Mixed & Heterogeneous Feeds. Processes coal with gangue, demolition waste, or recycled concrete efficiently, with adjustable tooth configurations (straight/spiral/wolf-tooth) for optimal fragmentation.

CSTMG Mineral Sizer Production Details

Material Selection & Preparation

- Rollers and shafts: Forged from 42CrMo alloy steel with ultrasonic testing for internal defects.

- Teeth: Tungsten carbide tips (HRC≥65) brazed in vacuum furnaces for maximum adhesion.

- Frame: Constructed from NM400 wear-resistant steel (Brinell hardness 400) for extended service life.

Precision Machining

- CNC-controlled milling of critical components with ±0.05mm tolerance.

- Gear machining to AGMA Class 9 standards for smooth power transmission.

- Dynamic balancing to G6.3 grade (vibration ≤2mm/s at full load).

Automated Assembly

- Robotic welding of structural components with post-weld stress relief.

- Laser-aligned bearing installation for perfect shaft concentricity.

- Computer-controlled torque application for all fasteners.

CSTMG Mineral Sizer Working Principle

The CSTMG Mineral Sizer operates on an advanced dual-roll crushing principle that delivers superior size reduction for various materials.

As raw material enters the crushing chamber, the counter-rotating toothed rollers grip and progressively break down the feed through a combination of compressive and shear forces.

The intermeshing teeth create multiple crushing zones that ensure uniform particle sizing while minimizing fines generation to less than 5%.

A key advantage is the adjustable gap control system (10-200mm range) that allows precise output sizing customization. The self-cleaning tooth design prevents material buildup, enabling reliable processing of sticky or high-moisture materials (up to 25% water content).

Compared to traditional crushers, this innovative mechanism offers 30-50% better energy efficiency and significantly lower wear rates

Proven Applications – Is Your Material Suitable?

Coal & Lignite (Energy Sector)

- The Challenge: Traditional crushers pulverize coal into useless dust (fines), lowering its market value and creating safety hazards.

- The Sizer Solution: Our low-speed, high-torque shearing action snaps coal along its natural cleavage lines.

- Your Benefit: You get a uniform “Lump Coal” product with minimal fines generation. This maximizes the calorific value and sales price of your coal. We easily handle wet, raw coal mixed with shale that would clog a hammer mill.

Alluvial Gold & Clay (Pre-Processing)

- The Challenge: Sticky clay (“Saprolite”) is the enemy of jaw crushers. It packs the chamber, stops production, and requires manual cleaning—a dangerous and costly downtime.

- The Sizer Solution: CSTMG Sizers feature “inward-rotating” shafts with cleaning combs. The teeth actively clear each other with every rotation.

- Your Benefit: Zero Clogging. You can process high-moisture clay ores directly from the pit, even during the rainy season. This is crucial for keeping your wash plant running 24/7.

Limestone, Gypsum & Salts (Industrial Minerals)

- The Challenge: These materials are soft to medium-hard but can be abrasive or hygroscopic (absorb water). High-impact crushing wastes energy and creates too much powder.

- The Sizer Solution: We offer adjustable tooth profiles to control the exact output size (e.g., specific sizes for cement kiln feed or agricultural lime).

- Your Benefit: Energy Efficiency. Crushing soft rock with shear force uses 30-50% less electricity than impact crushers. A massive cost-saving for cement plants and chemical industries.

Marble, Granite & Hard Rock (Overburden & Waste)

- The Challenge: Quarry owners often have piles of “waste” rock—weathered granite, marble chips, or overburden—that are too small for blocks but too big for gravel sales.

- The Sizer Limitation & Strength: While Sizers are not for primary crushing of fresh, hard granite (use a Jaw for that), they are perfect for secondary resizing of weathered rock and quarry waste.

- Your Benefit: Turn your waste pile into a revenue stream. Process weathered overburden and “b-grade” stones into road base or construction aggregate quickly and cheaply, without the high wear costs of an impact crusher.

Mineral Sizer vs. Traditional Crusher

| Feature | Mineral Sizer | Jaw Crusher | Cone Crusher | Impact Crusher |

| Wet & Sticky Ore | Excellent. Self-cleaning teeth design prevents clogging. Perfect for Brazil’s rainy season. | Poor. Prone to choking and blocking with clay/mud. | Poor. Chamber packs easily with wet fines. | Medium. Risk of build-up on liners. |

| Fines Generation | Low. Produces uniform lumps. High value for coal/ore sales. | Medium. Produces jagged, irregular shapes. | High. Creates excessive dust and fines (waste). | Very High. Pulverizes material (profit loss). |

| Energy Consumption | Low. High torque, low speed (shear force). Saves electricity/diesel. | High. Requires heavy flywheels and high power. | High. Continuous compression requires massive power. | High. High-speed rotor consumes significant energy. |

| Foundation/Installation | Simple. Compact & lightweight. No heavy concrete foundation needed. | Complex. Heavy vibration requires massive concrete base. | Complex. Needs heavy infrastructure. | Medium. Needs vibration isolation. |

| Wear Parts Cost | Low. Slow rotation = less abrasion on teeth. | Medium. Jaw plates wear out, but unevenly. | High. Mantle/concave wear is significant. | Very High. Blow bars wear out fast on abrasive rock. |

| BEST USED FOR | Wet, Sticky, or Soft-to-Medium Hard Materials. (Coal, Wet Iron Ore, Clay, Gypsum, Salts, Weathered Rock). | Hard, Abrasive, Dry Rock (Primary Stage).(Granite, Basalt, River Stone, Quartz). | Hard Rock (Secondary/Tertiary Stage). (Making final aggregate for construction/roads) | Shaping & Soft Non-Abrasive Rock.(Limestone, Concrete Recycling, Sand Making) |

Optimized Auxiliary Equipment For Max Sizer Efficiency

Heavy-Duty Apron Feeder

Mineral Sizers are often used as primary crushers for large Run-of-Mine (ROM) materials. Dumping rocks directly from a truck can damage crusher teeth and cause “surging” (uneven flow).

Our Apron Feeders are built like tanks to withstand the impact of heavy rocks. They regulate the feed rate, ensuring the Sizer operates at optimal capacity without choking.

Best For: Primary stations where large, uneven rocks and wet muck need to be metered consistently into the crusher.

Trommel Scrubber

In some regions, clay and laterite can stick to valuable minerals (Gold, Diamonds, Iron). A Sizer breaks the material down, but it doesn’t clean it.

The CSTMG Mineral Sizer is the ideal “Pre-Conditioner” for a Trommel. It breaks down large clay balls and compacted lumps into manageable sizes (e.g., -150mm). This allows the Trommel Scrubber to thoroughly wash and liberate the minerals inside. Without a Sizer, large clay lumps would simply pass through the Trommel unwashed.

Best For: Alluvial Gold mining, Diamond recovery, and sticky Iron Ore washing plants.

Wobbler Feeder / Roller Screen

Placing a Wobbler Feeder before the Sizer performs a dual function: it feeds the material forward while letting the fine particles (sand, mud, small rocks) drop through gaps. This “Scalping” process removes up to 40% of the volume before it hits the crusher.

You effectively double your plant’s capacity, reduce wear on the Sizer teeth, and prevent the “cushioning effect” where fines stop the crusher from gripping large rocks.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.