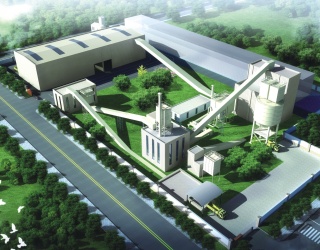

Metal Ore Crushing Plant

CSTMG metal ore crushing plant are engineered for seamless integration across the entire processing circuit, from primary feeding to final product stockpiling. Our heavy-duty conveyors feature impact-resistant idlers and wear-resistant belting to handle abrasive ores like iron and copper at capacities up to 6,000tph. The system incorporates intelligent transfer points with dust suppression and automated metal detection for operational safety. Designed for minimal material degradation, our handling solutions maintain optimal particle size distribution while reducing power consumption through regenerative drive technology. The modular design allows for quick maintenance and adaptability to various plant layouts, ensuring continuous material flow with 98% operational availability in demanding mining environments.

Hot Sale Metal Ore Crushing and Screening Equipment

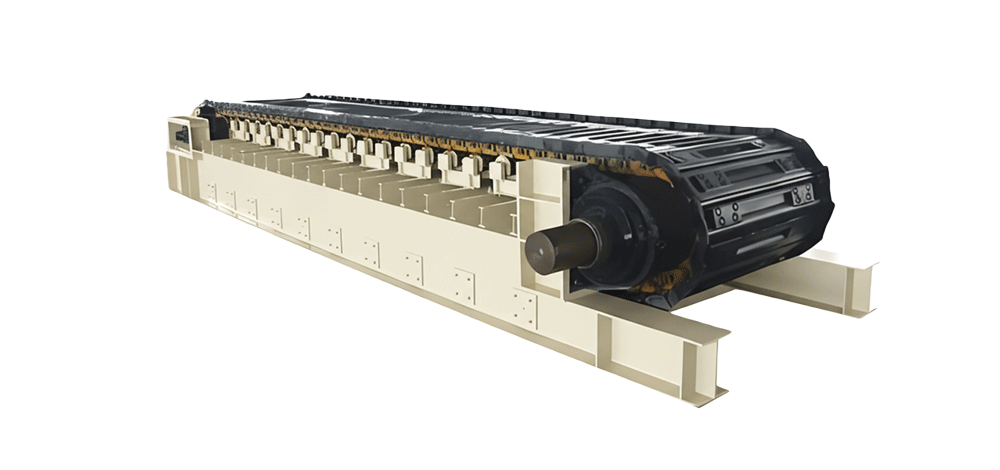

Apron Feeder

Length (m): 2-20

Capacity (m³/h): 50-4,000

Max feeding size (mm): 350-1,800

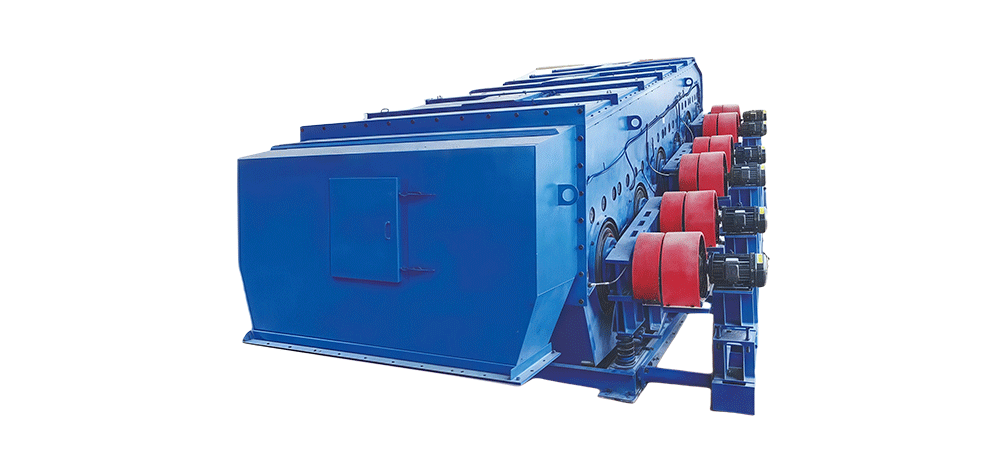

Feeder Breaker

Capacity (t/h): 500-5,000

Conveyor length (m): 6-30

Conveyor width (mm): 1,350-2,750

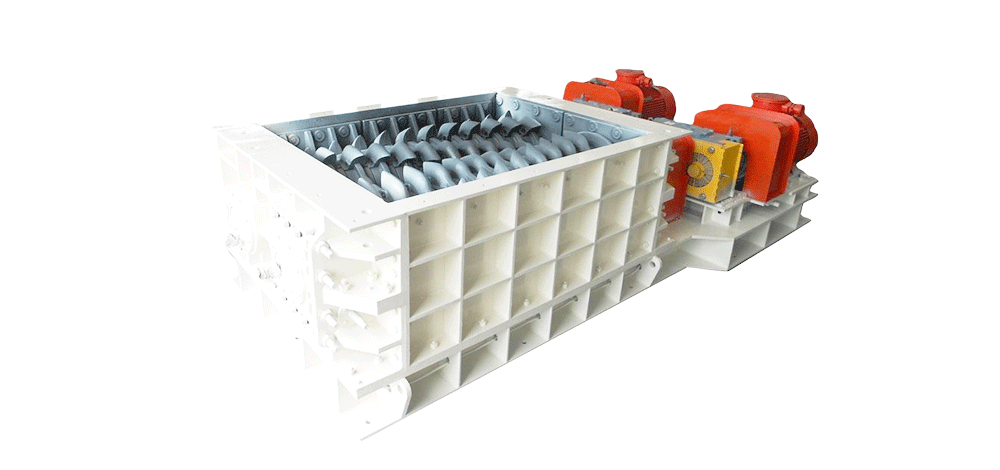

Mineral Sizer

Output size (mm): 50-300

Capacity (t/h): 250-10,000

Max feed size(mm): 200-1,500

Jaw Crusher

Output size (mm): 70-300

Capacity (t/h): 130-1,150

Max feed size(mm): 560-960

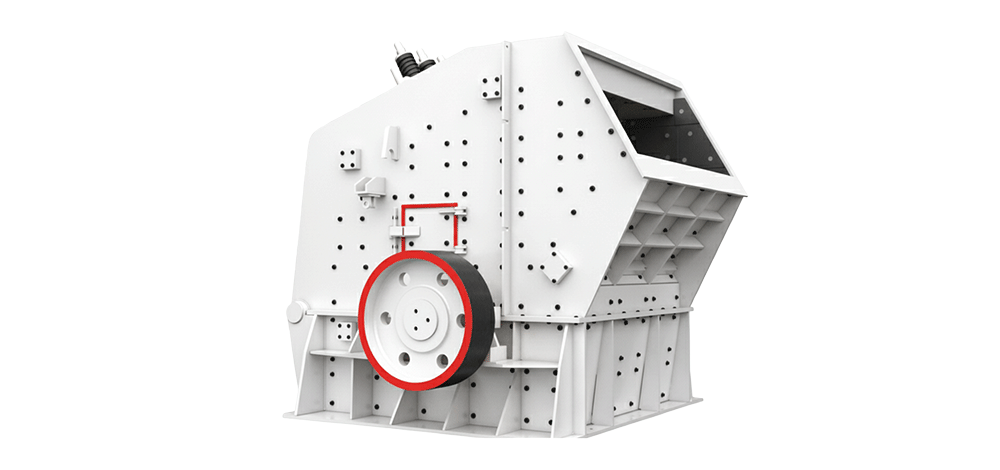

Impact Crusher

Rotor dia (mm): 1,300-1,600

Capacity (t/h): 300-1,000

Max feed size(mm): 600-800

Cone Crusher

Capacity (t/h): 27-1,270

Min. discharge size (mm): 9-38

Type: Single / Multi Cylinder

Hammer Crusher

Rotor dia (mm): 1,600-3,000

Capacity (t/h): 200-5,500

Max feed size(mm): ≤700-≤1,100

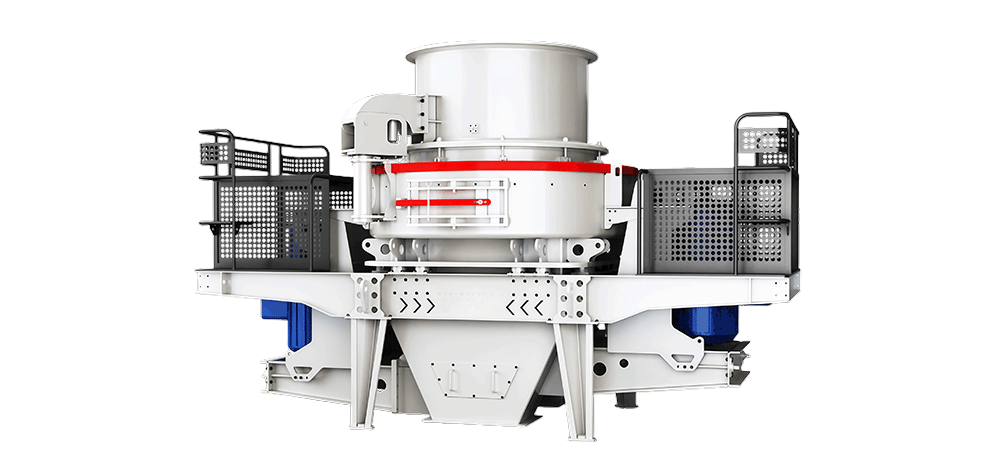

VSI Crusher

Capacity (t/h): 160-600

Max. input size (mm): 40-60

Rotating speed (rpm): 900-1,500

Mobile Crusher Plant

Capacity (t/h): 5-1,000

Feeding Size (mm): 0-350

Type: Crawler/Wheeled

Roller Screen

Capacity (t/h): 150-1,800

Screen Width (mm): 1,200-2,400

Graded Particle Size (mm): 10-100

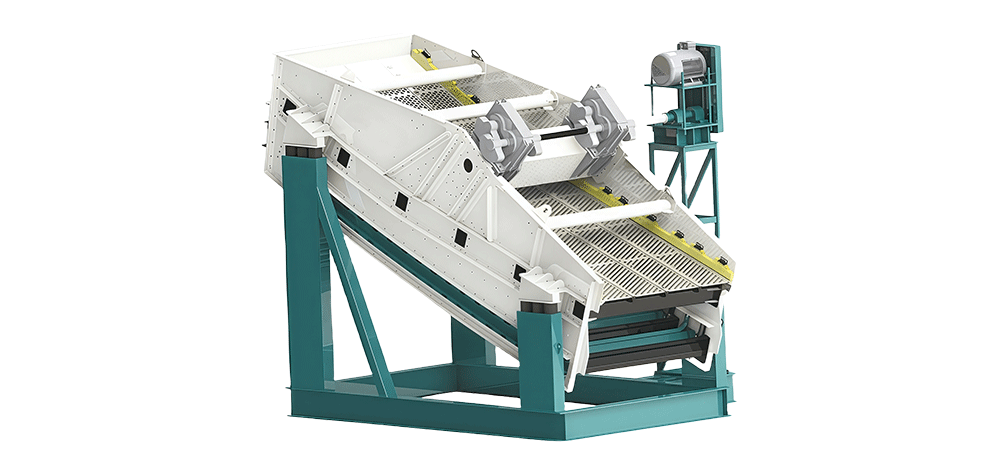

Flip Flow Screen

Capacity (t/h): 150-1,400

Feed size (mm): ≤80-≤100

Type: Mechanical/Vibrating

Circular Vibrating Screen

Number of Layers: 2-3

Capacity (t/h): 60-1,500

Max Input Size (mm): 200

Linear Vibrating Screen

Number of Layers: 1-2

Capacity (t/h): 40-950

Max Input Size (mm): 100

Environmental Screen

Number of Layers: 2-3

Capacity (t/h): 120-1,300

Max Input Size (mm): 200

VSI Crusher

Capacity (t/h): 120-520

Soft material max. feed size (mm): 35-60

Hard material max. feed size (mm): 30-50

Hot Sale Mining Beneficiation Equipment

CSTMG Metal Ore Crushing Plant Structure

CSTMG’s metal ore crushing plants feature a robust, modular structure engineered for high performance in demanding mining environments. The system integrates primary crushing with jaw crushers or gyratory crushers, secondary/tertiary crushing using cone crushers or impact crushers, and precision screening with vibrating screens — all supported by heavy-duty vibrating feeders and wear-resistant belt conveyors. Our intelligent PLC-based control system enables real-time monitoring, automated operation, and remote diagnostics for optimized efficiency and safety.

Available in customized configurations for open-pit, underground, or mobile operations, our plants efficiently process a wide range of metal ores — from hard iron and copper ores to abrasive nickel and chromium-bearing materials — ensuring maximum throughput, minimal downtime, and superior product quality.

Feeding

Our feeding systems are engineered for optimal material delivery to primary crushers, ensuring smooth, efficient processing of abrasive ores like iron, copper, and gold. Our heavy-duty vibrating grizzly feeders and apron feeders are equipped with wear-resistant components such as 20mm-thick AR steel pans for extended durability. The system intelligently adjusts feed rates based on real-time crusher load data, preventing overloads and minimizing downtime. Designed for zero spillage and low maintenance, our feeding solutions integrate seamlessly with IoT platforms for remote monitoring and predictive maintenance.

Types of Feeding Equipment

Crushing

CSTMG plants deliver high-performance processing for iron, copper, and gold ores through optimized primary, secondary, and tertiary crushing stages. Our systems feature advanced jaw crushers, cone crushers, and impactors that achieve precise 0-50mm particle sizing while minimizing energy consumption and fines generation. Engineered with wear-resistant components and smart automation for real-time adjustments, these plants offer 200-5,000tph capacity with 30% lower operating costs than conventional systems. The modular design ensures easy maintenance and adaptability to various ore characteristics. Custom configurations are available to match specific production requirements.

Types of Crushing Equipment

Screening

CSTMG’s metal ore screening systems ensure precise particle classification with multi-layer vibrating screens and banana screens and with other screen types for efficient separation. Designed for high-capacity operations (up to 5,000tph), they minimize fines loss while handling abrasive ores like iron and copper. Featuring wear-resistant polyurethane decks/steel ones and smart vibration control, our screens deliver consistent grading accuracy with low energy consumption and minimal maintenance requirements for optimal crushing circuit performance.

Types of Screening Equipment

Grading

CSTMG’s grading and classification systems ensure precise ore separation through advanced vibrating screens and hydrocyclones. Designed for efficient particle sizing (0-50mm), our solutions optimize metal recovery rates while minimizing energy use. The robust construction handles abrasive materials like iron and copper ores, delivering consistent performance with low maintenance. Smart automation enables real-time adjustments for maximum efficiency in high-capacity crushing circuits.

Types of Grading Equipment

Flotation

CSTMG’s flotation system enhances metal recovery through optimized air injection and reagent dosing for efficient ore separation. Designed for copper, gold, and polymetallic ores, it delivers high concentrate grades with low energy consumption. The robust system features wear-resistant components and smart controls for real-time process adjustments, ensuring stable performance in high-capacity mineral processing operations while minimizing chemical consumption and operational costs.

Types of Flotation Equipment

Dewatering

CSTMG’s dewatering system efficiently removes moisture from processed ores using high-capacity thickeners and filter presses. Designed for iron, copper, and gold concentrates, it achieves up to 93% water recovery with low energy consumption. The robust construction handles abrasive slurries while smart controls optimize performance. This system reduces tailings volume and improves product handling in high-capacity mineral processing operations.

Types of Dewatering Equipment

Metal Ore Crushing Plant Material Handling

Metal ore crushing plants handle various raw and processed materials throughout the mineral extraction and processing chain. The primary materials include iron ore, copper ore, gold ore, and other metallic minerals in their natural or partially processed states. These plants also manage byproducts like crushed rock, ore fines, and tailings generated during the crushing and screening processes.

Iron Ore

Copper Ore

Gold Ore

Lead-Zinc Ore

Molybdenum Ore

Nickel Ore

CSTMG Crusher Plant Design and Installation Projects

CSTMG Mining Equipment: Optimized for Gold Processing Efficiency

CSTMG provides more than just machinery; we provide end-to-end, optimized process solutions tailored to your ore body, scale, and environment, guaranteeing maximum efficiency and return on investment.

At CSTMG, we design high-performance mining equipment tailored to maximize gold recovery at every stage—from crushing to refining.

1. Ore Crushing: Precision & Durability

- Mobile Crushers – Ideal for small-to-medium mines, easy to relocate.

- Stationary Crushers – High-capacity (5-1500t/h) for large-scale operations.

- Material-Specific Liners – Manganese steel for hard rock, lighter builds for alluvial gold.

- ✅ Proven Results: A Brazilian mine saw 25% higher efficiency and 8-month liner lifespan.

2. Gold Concentration: Maximize Recovery (90%+)

- Shaking Tables – Ultra-flat (≤0.5mm) rubber decks for precise separation.

- Thickeners – Smart controls for automated slurry management.

- ✅ Case Study: A Gansu placer mine boosted recovery from 85% to 92%.

3. Gold Extraction: Efficient & Eco-Friendly

- Dry Washers – Waterless processing for arid regions.

- Cyanide-Free Leaching – Environmentally compliant for high-grade ore.

- Elution Systems – ≥98% recovery with fully automated operation.

4. Gold Refining: 99.99% Purity

- Compact Refiners – Small-scale (1-10kg/day), easy to operate.

- Electrolytic Refiners – High-volume, high-purity production.

- ✅ Features: Titanium electrodes + integrated metal recovery.

5. Custom Solutions for Unique Needs

- Mobile Units – Quick setup, multi-voltage support.

- Dry Mining Plants – No water needed, dust-controlled.

- Alluvial Mining Machines – Integrated washing & recovery.

About CSTMG

As an industry leader with 60+ patents and ISO 9001 certification, CSTMG combines cutting-edge engineering with decades of mining expertise to deliver superior coal crushing solutions.

CSTMG solutions are backed by comprehensive technical support and customizable wear protection packages tailored to each ore type’s abrasiveness and crushability. Our crushing circuits demonstrate exceptional reliability in processing iron, copper, gold, and polymetallic ores, consistently meeting stringent size reduction targets with minimal fines generation.

CSTMG Global Cases

Crushing and Screening Plant Works in Kenya

Aggregate Crusher Plant Operates in Serbia

Coal Crushing & Screening Plant in Indonesia

How to Choose Ore Crushing Plant For Different Site Conditions?

Selecting the right crushing plant is crucial for optimizing efficiency and recovery in metal ore processing. The ideal equipment varies based on ore type, processing scale, and site-specific conditions.

1. Consider Processing Scale and Mobility

- Small to Medium Mines: Choose mobile crushing plants for flexibility, easy relocation, and cost-effective deployment across multiple sites.

- Large-Scale Operations: Opt for stationary crushing plants with high-capacity throughput (e.g., 5–500 t/h) to handle continuous, high-volume processing.

2. Match Equipment to Ore Type and Hardness

- Hard Rock Ore (e.g., Lode Gold): Use crushers with high-manganese steel liners for enhanced wear resistance and impact durability.

- Alluvial/Soft Ore (e.g., Placer Gold): Select light-duty crushers to avoid over-crushing and preserve gold particle integrity.

3. Optimize Downstream Recovery with Specialized Equipment

- Concentration:

- Use double-deck shaking tables for fine-grained ore and single-deck models for coarse gold recovery.

- Employ deep-cone thickeners for high-density slurries and center-drive thickeners for energy-efficient, low-density slurries.

- Extraction:

- Alluvial Ores: Implement bucket-wheel washing plants for integrated scrubbing and recovery.

- Water-Scarce Sites: Utilize dry processing systems (e.g., dry washers, air concentrators).

- Leaching: Apply cyanide-free leaching for high-grade eco-friendly processing, or heap leaching for low-grade ores.

- Refining:

- Small-Scale: Use compact refining units.

- Large-Scale: Implement electrolytic refining systems for ≥99.99% purity and high-volume output.

4. Adapt to Site Conditions

- Arid/Dry Regions: Implement a full dry processing circuit (crusher + concentrator + shaking table) with dust control systems.

- Alluvial Deposits: Choose semi-mobile washing plants with built-in scrubbing, screening, and recovery modules.

- Remote/Dispersed Sites: Use mobile or modular crushing-washing units with quick setup (≤2 hours), multi-voltage support, and compact designs.

5. Key Selection Principles

- Prioritize modular and integrated systems to avoid bottlenecks and reduce operational costs.

- Look for smart and automated features (e.g., remote monitoring, automated slurry control) to improve efficiency and lower labor needs.

- Consider customizable solutions tailored to specific ore properties and geographic constraints.

How Does Metal Ore Crushing Plant Work?

The metal ore crushing plant, as illustrated in the ilmenite beneficiation flow chart, operates through a meticulously designed sequence of comminution and separation stages. The process begins with primary crushing, where raw run-of-mine (ROM) ore is consistently fed by a vibrating grizzly feeder into a PE (Primary Efficiency) Jaw Crusher. This initial stage reduces large, coarse ore lumps to a manageable size.

The output from the jaw crusher is then conveyed to a secondary crushing stage, typically performed by a Cone Crusher. This equipment further reduces the ore particle size, ensuring it is prepared optimally for the subsequent grinding circuit.

Following secondary crushing, the crushed material is directed onto a Vibrating Screen (or a multi-deck screen series) for particle size classification. The oversize material (which does not meet the target size specification) is recirculated back to the cone crusher for further reduction in a closed-loop system. The correctly sized, or “screen undersize,” product is discharged and transported to a small-size ore bin, which acts as a regulated surge capacity hopper, ensuring a steady and continuous feed for the downstream grinding mills.

From the ore bin, the material is fed via a belt feeder or conveyor into Ball Mills for the grinding (or tertiary crushing) phase. Here, the ore is pulverized with steel balls to liberate the valuable mineral grains (ilmenite) from the worthless gangue material, creating a slurry.

The subsequent processes include:

- Classification: The ground slurry is fed into hydrocyclones or spiral classifiers, which separate particles based on size and density. The coarse particles are returned to the ball mill for further grinding (forming a closed grinding circuit), while the fine slurry proceeds.

- Desliming: This critical step removes ultra-fine clay and silt particles (slimes) that can interfere with the efficiency of the downstream magnetic separation. This is often also achieved using hydrocyclones.

- Magnetic Separation: The deslimed slurry is processed through a High-Gradient Magnetic Separator (HGMS). Ilmenite is a ferromagnetic mineral, and the HGMS powerfully attracts and separates it from the non-magnetic gangue minerals, producing a magnetic concentrate.

- Concentration and Filtration: The magnetic concentrate may undergo additional cleaning steps and is then thickened to increase solids density. Finally, it is dewatered using Disc Filters or a similar filtration system to create a damp filter cake, which is the final ilmenite concentrate product ready for transport or further processing.

Throughout this process, the non-magnetic tailings from the magnetic separator are channeled to a tailings storage facility (TSF) for responsible, environmentally sound disposal, often involving water recovery and recycling.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.