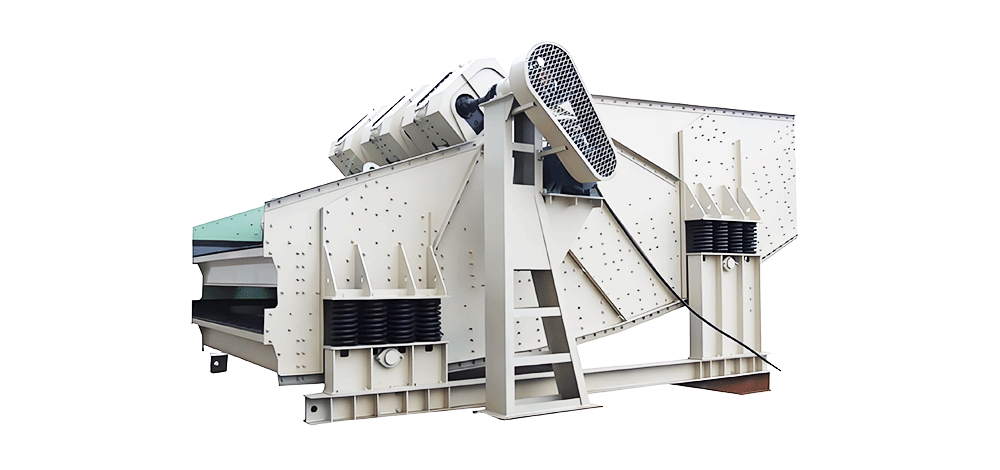

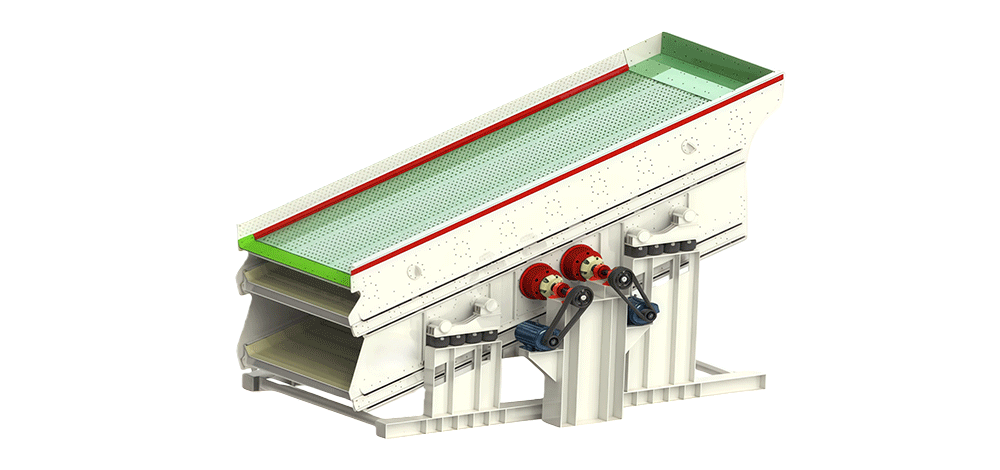

Linear Vibrating Screen

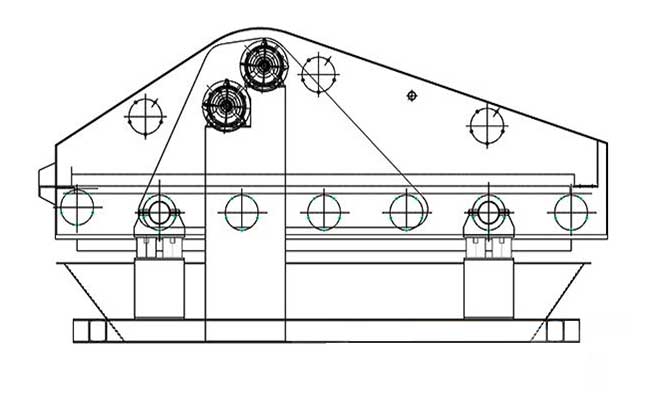

CSTMG linear vibrating screen uses dual vibration motors to generate straight-line motion, efficiently separating materials by size. Ideal for dry or wet classification, it features high screening accuracy, large capacity, and low energy consumption. The robust design handles minerals, chemicals, grains, and recycled materials. Adjustable amplitude and frequency optimize performance for different applications. With simple maintenance and durable construction, it’s widely used in mining, and coal crushing for precise grading and dewatering operations.

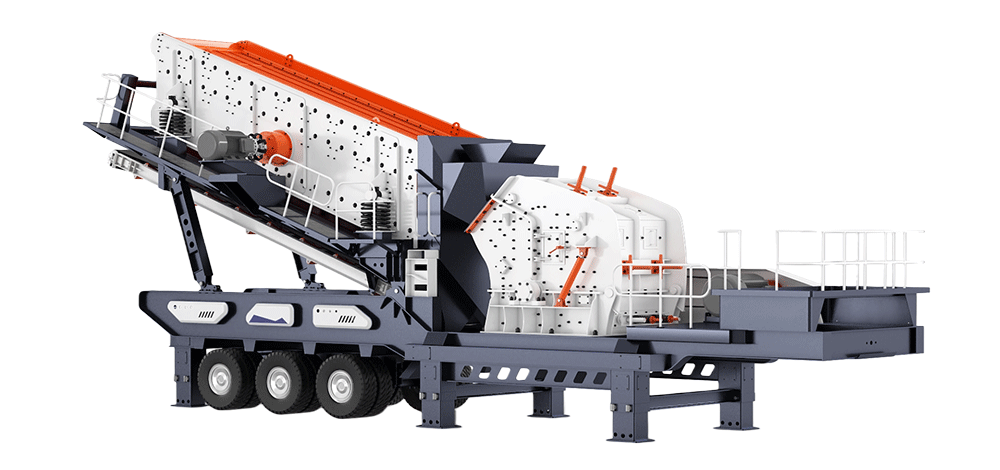

APPLICATIONS

Coal

Mining

CSTMG Linear Vibrating Screen Features

Straight-Line Motion. Dual vibration motors generate synchronized linear vibration, ensuring uniform material flow and efficient stratification for accurate size separation.

High Screening Efficiency. Adjustable amplitude (2-8mm) and frequency (700-1200 RPM) optimize material penetration, achieving 80-95% efficiency for dry/wet classification.

Large Processing Capacity. Wide-screen designs handle high-volume materials like coal, ores, and aggregates at 40-950 t/h throughput.

Multi-Layer Classification. Configurable with 1-2 decks (e.g., 2-layer for 3-50mm/0.5-15mm grading) to replace multiple screens in one unit.

Robust Construction. High-strength steel frame and crossbeam reinforcement withstand heavy loads with minimal deformation.

CSTMG Linear Vibrating Screen Specification

| Model | Screen Plate | Max. Input Size | Capacity | Electrical Motor | |||

| Layer(s) | Area(m²) | Mesh Size(mm) | (mm) | (t/h) | Power(kw) | Qty(pcs) | |

| CSTMG – DZX1848 | 1 | 8.64 | 0.5-15 | 100 | 40-100 | 22 | 1 |

| CSTMG – 2DZX1848 | 2 | 8.64×2 | Upper:3-50 Lower:0.5-15 | 100 | 70-300 | 30 | 1 |

| CSTMG – DZX2448 | 1 | 11.52 | 0.5-15 | 100 | 40-120 | 30 | 1 |

| CSTMG – 2DZX2448 | 2 | 11.52×2 | Upper:3-50 Lower:0.5-15 | 100 | 100-450 | 45 | 1 |

| CSTMG – DZX2461 | 1 | 14.64 | 0.5-15 | 100 | 40-130 | 37 | 1 |

| CSTMG – 2DZX2461 | 2 | 14.64×2 | Upper:3-50 Lower:0.5-15 | 100 | 100-550 | 45 | 1 |

| CSTMG – DZX3061 | 1 | 18.3 | 0.5-15 | 100 | 40-300 | 45 | 1 |

| CSTMG – 2DZX3061 | 2 | 18.3×2 | Upper:3-50 Lower:0.5-15 | 100 | 100-700 | 55 | 1 |

| CSTMG – DZX3661 | 1 | 21.96 | 0.5-15 | 100 | 40-370 | 55 | 1 |

| CSTMG – 2DZX3661 | 2 | 21.96×2 | Upper:3-50 Lower:0.5-15 | 100 | 100-830 | 75 | 1 |

| CSTMG – DZX4361 | 1 | 26.23 | 0.5-15 | 100 | 40-450 | 55 | 1 |

| CSTMG – 2DZX4361 | 2 | 26.23×2 | Upper:3-50 Lower:0.5-15 | 100 | 100-950 | 75 | 1 |

CSTMG Linear Vibrating Screen Worldwide Cases

CSTMG Linear Vibrating Screen Delivered to United Arab Emirates

CSTMG Linear Vibrating Screen Delivered to United Arab Emirates

CSTMG Linear Vibrating Screen Ready to Be Sent to Tanzania

Linear Vibrating Screen Handling Materials

Coal & Carbon Materials. Processes raw coal (0-300mm), removing gangue and moisture. Separates crushed coal into lump/particle sizes (e.g., >25mm for coking, <6mm for power plants). Handles coal slurry dewatering (15-25% moisture reduction) in washing plants.

Metal Ores. Screens iron/copper ores post-crushing (50-150mm feed). Grades ores into coarse (>30mm for recrushing), medium (10-30mm for grinding), and fines (<10mm for beneficiation). Recovers 90%+ valuable minerals from tailings.

Aggregates & Quarry Stone. Separates quartz (for glass), kaolin (ceramics), and gypsum by size (0.1-10mm). Handles high-purity (>98%) grading with stainless steel screens.

CSTMG Linear Vibrating Screen Production Details

Advanced Screening System

- Multi-layer configuration: 1-2 decks with independent aperture settings

- Adjustable deck angles: 0°-5° tilt adjustment for optimal material flow control

- Specialized screen media: Options include polyurethane panels (for wet materials), rubber-coated meshes (abrasive ores), and stainless steel wire cloth (food-grade applications)

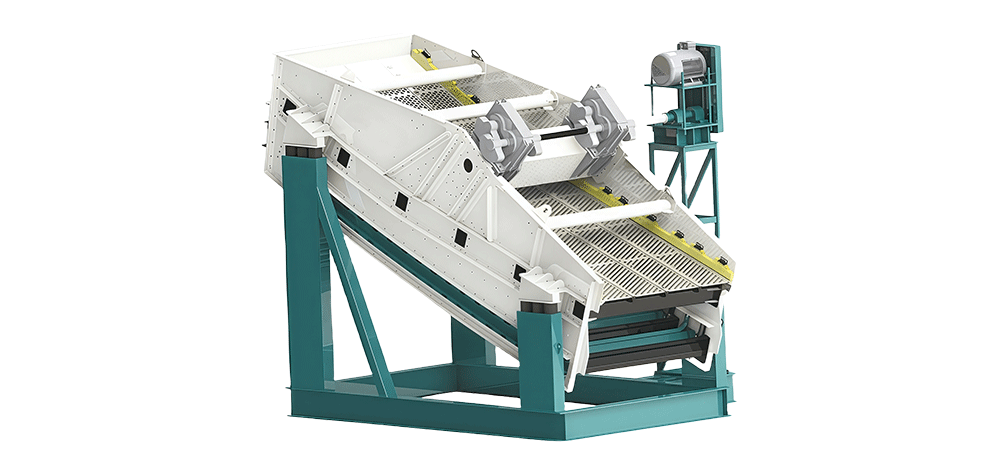

Dual-Motor Drive System

- CSTMG linear vibrating screen features twin vibration motors operating in synchronized counter-rotation, generating combined excitation forces of 7-10mm amplitude at 960-980r/min. The motors’ adjustable installation angles (15°-25°) optimize material throwing distance and travel speed for different materials, enhancing screening efficiency while reducing energy consumption by 15-20% compared to single-motor designs.

Heavy-Duty Structural Design

- Constructed with high-tensile steel plates (Q345B grade), the screen box utilizes bolted/riveted connections at stress points to withstand ≤100mm feed size impacts.

CSTMG Linear Vibrating Screen Working Principle

The linear vibrating screen operates on a precisely engineered dual-motor excitation system that generates controlled linear vibration for efficient material separation. At the core of its operation are two identical vibration motors mounted symmetrically on the screen body, each equipped with adjustable eccentric weights. When these motors rotate synchronously in opposite directions, they create a unique force dynamic: along the motor axis direction, the opposing centrifugal forces cancel each other out, eliminating lateral movement; while perpendicular to the motor axis, the forces combine to produce a powerful linear excitation force that drives the entire screening assembly.

This carefully calibrated vibration system produces a consistent linear motion with adjustable amplitude (typically 7-10mm) and frequency (commonly 960-980 RPM). The motors are installed at a specific angle to the screen surface (usually between 15°-25°), creating both horizontal and vertical force components. The horizontal component propels material forward along the screen deck, while the vertical component creates the characteristic “throw and catch” action that is essential for effective particle separation. This dual-action mechanism ensures material moves continuously toward the discharge end while simultaneously being agitated for optimal size separation.

Material processing occurs through three distinct phases. During the upward vibration stroke, particles are thrown vertically, allowing finer materials to descend toward the screen surface while coarser particles remain on top. As the screen reverses direction in the downward stroke, gravity and vibration forces work together to drive properly sized particles through the screen apertures. Oversized particles continue their journey along the screen surface, benefiting from the consistent linear motion that prevents material pile-up and ensures even distribution across the full screening area.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.