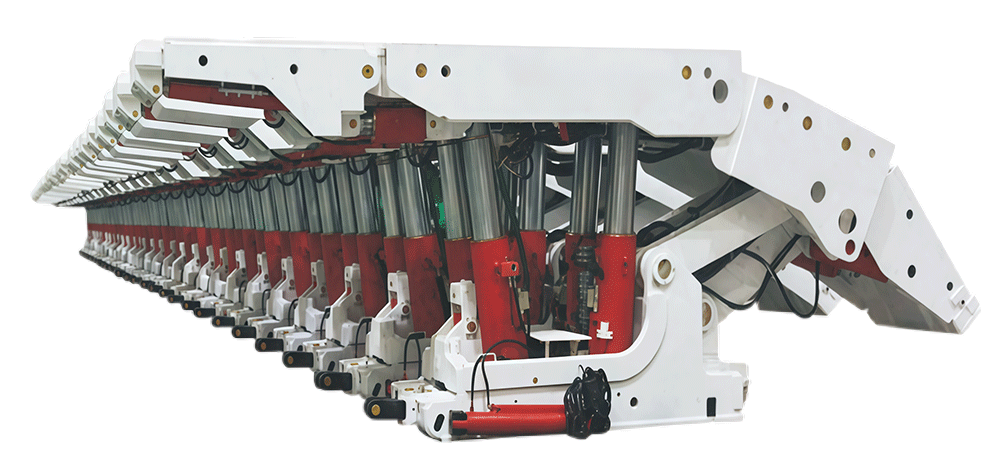

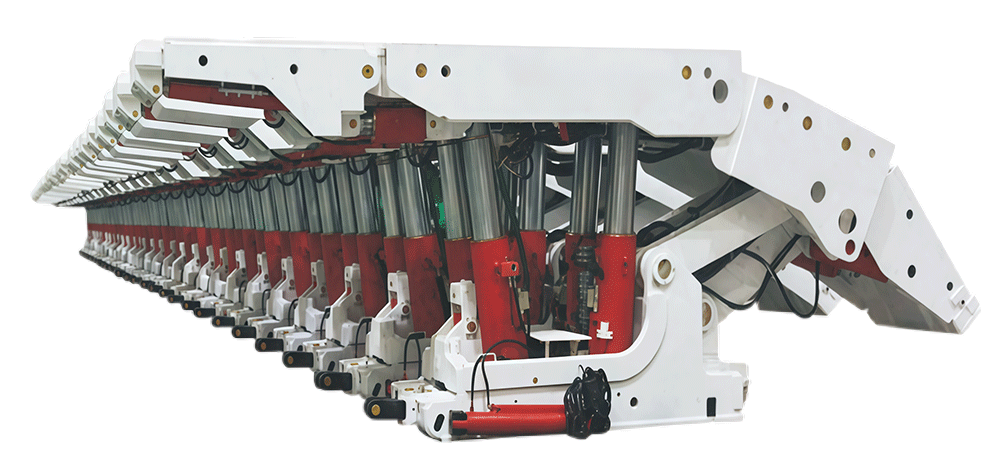

Hydraulic Support

Looking for reliable roof support systems? CSTMG offers a comprehensive range of hydraulic supports for sale, engineered for modern longwall mining.

We specialize in solving complex geological challenges. Our inventory includes fully mechanized top-coal caving supports, steep-seam solutions, and intelligent electro-hydraulic shields.

As a leading manufacturer and direct supplier, we provide high-performance roof control solutions designed to withstand the most demanding underground environments. From thin seams to massive ultra-high working faces, our equipment is built to maximize uptime and ensure personnel safety.

APPLICATIONS

Coal

Mining

Top Coal Caving Supports For Sale

CSTMG – ZFA10000/22/35D Four Pillar Support Shield Type Hydraulic Support For Top Coal Caving

Suitable for up-dip mining faces in thick coal seams.

CSTMG – ZFY4800/17/32 Type Two Column Cover Type Hydraulic Support For Top Coal Caving

Suitable for fully mechanized top-coal caving faces in steep, thick coal seams.

CSTMG – ZF6400/16/30Q Large Angle Caving Coal Hydraulic Support

Suitable for steep (up to 50°) fully mechanized top-coal caving faces with soft roof, soft coal, and soft floor.

CSTMG – ZF8600/18/35D Four Pillar Support Shield Type Hydraulic Support For Top Coal Caving

Suitable for intelligent, high-efficiency, high-production top-coal caving faces in thick seams.

CSTMG – ZF12000/17/32 Type Four Pillar Support Shield Hydraulic Support For Top Coal Caving

Suitable for fully mechanized top-coal caving faces in thick coal seams.

CSTMG – ZF18000/21/38D Four Pillar Support Shield Type Hydraulic Support For Top Coal Caving

Suitable for intelligent, high-efficiency, high-production top-coal caving faces in thick seams.

Shield Supports For Sale

CSTMG – ZY18800/30/65D Two Column Shield Hydraulic Support

Suitable for large mining height fully mechanized faces in thick coal seams.

CSTMG – ZY8600/12/24D Two Column Shield Hydraulic Support

Suitable for fully mechanized mining faces in thin coal seams.

Support Shield Bracket For Sale

CSTMG – ZZ9000/16/32 Type Four Column Support Shield Hydraulic Support

Suitable for fully mechanized mining faces in medium-thick coal seams.

Special Supports For Sale

CSTMG – ZFT25000/30/60D Ultra High End Head Bracket

Suitable for thick seam top coal caving faces.

CSTMG – ZLH2x4200/24/34D Sliding Advanced Hydraulic Suppor

Suitable for advanced support in coal mine roadways.

CSTMG – ZQ5000/17/35D Intelligent Adaptive Unit Support

Suitable for advanced support in the roadways for fully mechanized faces and gob-side entry retaining support.

CSTMG Hydraulic Support Advantages

Designed and manufactured in line with the highest international industry standards, our hydraulic supports are tailored to diverse coal mining conditions worldwide, providing stable and efficient support solutions for modern coal mines and empowering the transformation of the coal mining industry towards safety, high efficiency, and intelligence.

1. Outstanding Load-Bearing Capacity & Structural Reliability

CSTMG hydraulic supports feature a robust structural design with high-strength alloy steel as the main material, which undergoes strict heat treatment and quality inspection processes. The optimized four-link or six-link mechanism ensures that the top beam maintains a vertical support state during lifting and lowering, effectively preventing tilting and toppling.

With a maximum working resistance of up to 15,000 kN, our hydraulic supports can easily adapt to complex roof conditions such as hard roofs, broken roofs, and thick coal seams, providing strong support for roof stability and effectively avoiding safety hazards such as roof collapse and gangue fall.

2. High Automation & Efficient Operation

Equipped with an advanced hydraulic control system and intelligent control module, CSTMG hydraulic supports realize full-process automated operations including roof support, frame moving, and conveyor pushing.

The intelligent following-machine support function can seamlessly cooperate with shearers, realizing synchronous movement with a frame moving speed of less than 8 seconds per frame, which greatly matches the high-yield and high-efficiency mining needs of modern coal mines.

In addition, the supports support multiple control modes such as single-frame manual control, group linkage, and full-automatic unmanned control, effectively reducing manual intervention and improving operation efficiency.

3. Strong Adaptability to Diverse Working Conditions

CSTMG has rich experience in customizing hydraulic support solutions for different mining conditions.

Our product portfolio covers various types of hydraulic supports such as roof support type, shield type, and support-shield type, which can be tailored to coal seams of different thicknesses (thin coal seam, medium-thick coal seam, thick coal seam), different dip angles (ordinary dip angle, large dip angle), and different roof properties.

For special working conditions such as large-dip angle coal seams and fully mechanized caving mining, we have developed professional anti-skid, anti-toppling, and high-efficiency caving structures, ensuring stable operation in extreme environments.

4. Advanced Intelligent Monitoring & Safety Guarantee

Our hydraulic supports are integrated with intelligent monitoring systems based on 5G, Internet of Things, and visual recognition technologies. The real-time monitoring of key parameters such as support resistance, hydraulic system pressure, and roof settlement can be realized, and abnormal data can be alarmed and early warned in time, helping managers grasp the working status of the equipment and the roof condition accurately.

The fully enclosed shield structure and side guard plate design effectively prevent gangue intrusion and coal wall spalling, creating a safe working environment for operators. At the same time, the built-in safety valves and pressure relief devices ensure the safe and stable operation of the hydraulic system, avoiding accidents caused by overpressure.

5. Energy-Saving & Environmental Protection & Long Service Life

We adheres to the concept of green development, and the hydraulic supports adopt high-efficiency and energy-saving hydraulic components and pipeline systems, which reduce energy consumption while ensuring strong power output.

The use of environmentally friendly emulsion as the power medium is non-toxic and pollution-free, complying with international environmental protection standards.

In addition, all key components of the supports are subject to strict wear-resistant and corrosion-resistant treatment, which significantly improves the service life of the equipment. The modular design facilitates maintenance and replacement of components, reducing maintenance costs and downtime for customers.

6. Professional Customization & Global Service Support

Based on the global coal mining market, CSTMG has a professional R&D team and technical service team that can provide customers with one-stop solutions from demand analysis, product design, manufacturing, installation and commissioning to after-sales maintenance.

Our after-sales service network covers major coal-producing regions around the world, providing 24/7 technical support and spare parts supply, ensuring the continuous and stable operation of customers’ mining equipment.

CSTMG hydraulic supports are committed to becoming the core driving force for the intelligent transformation of the global coal mining industry. With reliable quality, advanced technology and perfect service, we help customers improve mining efficiency, reduce safety risks and create greater value.

CSTMG Hydraulic Support Worldwide Cases

CSTMG Hydraulic Support Operation in Indonesia

CSTMG Coal Hydraulic Support Operation in Russia

CSTMG Hydraulic Support Ready to Be Sent to Australia

What Is A Hydraulic Support?

A hydraulic support, also known as a powered roof support or shield, is the structural backbone of a modern underground longwall mining system.

As a key component of the “four machines and one support” system (shearer, scraper conveyor, transfer conveyor, and hydraulic support) in fully mechanized mining, it plays an irreplaceable role in ensuring mining safety, improving production efficiency, and promoting intelligent mining transformation.

Powered by high-pressure emulsion, hydraulic supports realize a series of automatic actions such as lifting, lowering, moving, and conveyor pushing through the expansion and contraction of hydraulic cylinders. Its core function is to provide timely and reliable support for the roof of the mining face, preventing roof collapse, gangue falling, and coal wall spalling, thus creating a safe and stable working space for mining equipment and operators.

Key Components of Hydraulic Supports

A standard hydraulic support is composed of two core parts: the steel structure and the hydraulic system, supplemented by auxiliary components to ensure comprehensive performance:

Auxiliary components: Such as spray systems (dust reduction and cooling), anti-skid and anti-toppling devices (for steeply inclined working faces), and coal wall protection jacks (preventing coal wall spalling).

Steel structure (load-bearing main body): Including top beam (directly contacting the roof to transmit supporting force), shield beam (protecting the internal space from gangue intrusion), base (supporting the entire support and transmitting pressure to the floor), link mechanism (ensuring vertical support and preventing tilting), and side guard plate (preventing gangue from entering between adjacent supports).

Hydraulic system (power execution unit): Consisting of columns (core load-bearing hydraulic cylinders determining supporting height and force), pushing jacks (realizing support moving and conveyor pushing), balance jacks (adjusting the angle between top beam and shield beam), control valve group (the “control center” regulating the action of each cylinder), and pipeline system (connecting the pump station and cylinders to transmit high-pressure emulsion).

Wide Application of Hydraulic Supports

Our hydraulic supports are engineered with modular flexibility and specialized designs to cover the full spectrum of modern underground mining conditions.

From thin seams in difficult terrain to world-record height requirements, our equipment is successfully operating in the following scenarios:

1. Core Application Scenario: Underground Fully Mechanized Coal Mining Faces

The primary application scenario of hydraulic supports is underground fully mechanized coal mining faces, which are the core part of modern coal production. In these faces, hydraulic supports form a closed protective system with shearers, scraper conveyors, and other equipment, realizing the integration of coal cutting, support, and transportation.

Whether it is a large-scale mine with annual output exceeding 10 million tons or a medium-sized mine with moderate production scale, hydraulic supports are indispensable core equipment.

2. Adaptation to Diverse Geological and Mining Conditions

One of the key manifestations of the wide application of hydraulic supports is their strong adaptability to diverse geological and mining conditions. Through customized design and structural optimization, hydraulic supports can be tailored to different coal seam characteristics and underground environments, expanding their application boundaries:

Coal seam thickness adaptation: For thin coal seams (support height < 1.3m), medium-thick coal seams (1.3m – 3.5m), thick coal seams (3.5m – 5m), and extra-thick coal seams (>8m), there are corresponding thin-seam hydraulic supports, medium-thick seam hydraulic supports, large mining height hydraulic supports, and top-coal caving hydraulic supports. For example, large mining height hydraulic supports with a maximum support height of more than 8 meters are widely used in extra-thick coal seam mining projects, realizing one-time full-height mining.

Roof condition adaptation: Aiming at stable roofs, broken roofs, and soft roofs, different types of hydraulic supports such as chock-type, shield-type, and chock-shield-type are developed. Shield-type hydraulic supports with strong protective performance are widely used in faces with broken roofs and easy coal wall spalling, while chock-type hydraulic supports with large supporting force are suitable for faces with stable roofs.

Inclination angle adaptation: For gently inclined coal seams (inclination angle ≤ 15°), inclined coal seams (15° – 35°), and steeply inclined coal seams (>35°), hydraulic supports are equipped with anti-skid and anti-toppling devices, side guard plate reinforcement, and other structural designs. Steeply inclined hydraulic supports can maintain stable operation even in faces with an inclination angle of more than 45°, ensuring safe mining in complex inclined environments.

3. Special Tunneling & Roadway Applications

Beyond the main working face, CSTMG provides critical support for the tunnel infrastructure:

Gob-Side Entry Retaining: High-tech supports designed to hold the roof along the edge of the mined-out area (gob), allowing the tunnel to be reused for the next mining panel. This maximizes resource recovery and reduces tunnel excavation costs.

Advanced Roadway Support: Mobile temporary support units for the gate roads (tunnels) ahead of the advancing face, replacing traditional single props for better speed and safety.

4. Expansion to Special Mining Fields

With the continuous advancement of technology, the application of CSTMG hydraulic supports has gradually expanded to special mining fields beyond traditional coal mining:

- in the mining of coalbed methane, hydraulic supports provide stable support for the drilling and extraction working faces, ensuring the safety of extraction operations;

- in the mining of non-coal minerals such as phosphate rock and iron ore with similar underground mining conditions, hydraulic supports are also used for roof support, realizing the cross-industry application of this technology.

In addition, in the renovation of old mines and the mining of residual coal resources, hydraulic supports with flexible movement and strong adaptability play an important role in improving the utilization rate of coal resources.

Hydraulic Support Working Principle

The working process of hydraulic supports is driven by the hydraulic system, which mainly includes four basic actions:

Pushing the conveyor: While moving the support, the scraper conveyor is synchronously pushed forward to keep it closely aligned with the shearer, ensuring the continuity of the coal mining and transportation process.

Lifting the support: The hydraulic cylinder extends to push the top beam of the support to closely fit the roof, exerting a stable supporting force to balance the pressure of the overlying rock and ensure roof stability.

Lowering the support: The hydraulic cylinder retracts to make the top beam separate from the roof, creating space for the support to move forward.

Moving the support: Relying on the pushing hydraulic cylinder, the entire support is moved forward to the new mining position, following the mining progress of the shearer.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.