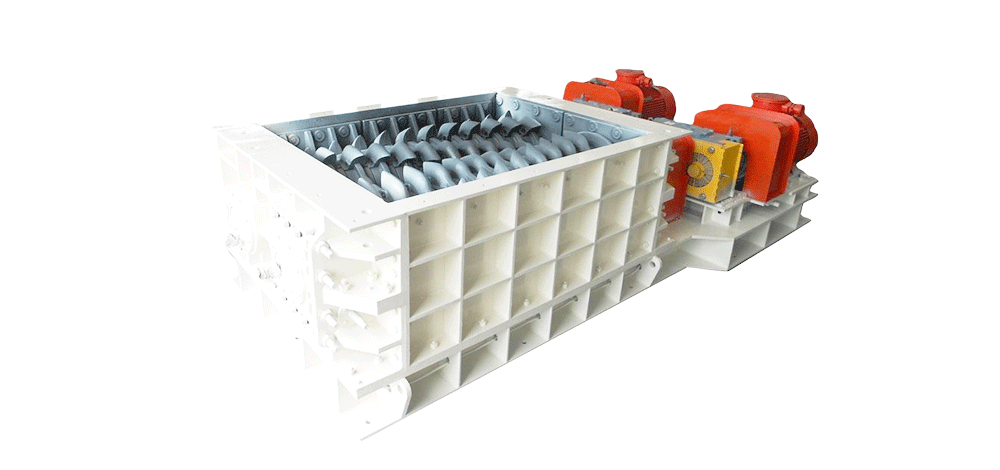

Four Roll Crusher

Our high-efficiency four roll crusher delivers superior size reduction for demanding applications. Ideal for crushing coal, coal gangue, and filter cake (feed size ≤300mm, compressive strength ≤120 MPa), it achieves a remarkable single-pass reduction to under 10mm.

Exceptional throughput, minimal fines generation, and an anti-clogging design for maximum uptime, CSTMG four roll cruhser is perfectly suited for the coal, mining, and mineral processing industries. Ready to boost your productivity? Contact us today for a detailed quote and discover the right model for your operation.

APPLICATIONS

Coal

Mining

Power

Chemical

CSTMG Four Roll Crusher Features

High Reduction Ratio. Four roll crushers can achieve significantly higher reduction ratios compared to single-stage crushers. While a standard double roll crusher might achieve a reduction ratio of 4:1, a four roll crusher can typically reach ratios of 8:1 or higher in a single pass, reducing large feed materials (up to 300mm) to fine products (under 10mm) efficiently.

Precise Product Size Control. The independent adjustment capability of both the primary and secondary crushing stages allows operators to precisely control the final product size. This is particularly valuable in applications where specific particle size distributions are critical to downstream processes.

Reduced Fines Generation. Four roll crushers utilize a combination of compression and shear forces that produce a more cubical product with reduced fines. This characteristic makes them ideal for applications where minimizing ultra-fine material is economically beneficial.

CSTMG Four Roll Crusher Specification

| Model | Max. Input Size (mm) | Output Size (mm) | Capacity (tph) | Power (kw) |

| CSTMG – 4G10-50 | 300 | 0-10 | 50 | 18.5+22 |

| CSTMG – 4G10-70 | 300 | 0-10 | 70 | 2×30 |

| CSTMG – 4G10-90 | 300 | 0-10 | 90 | 37+45 |

| CSTMG – 4G10-100 | 300 | 0-10 | 100 | 2×45 |

| CSTMG – 4G10-140 | 300 | 0-10 | 140 | 45+55 |

| CSTMG – 4G10-150 | 300 | 0-10 | 150 | 2×55 |

| CSTMG – 4G10-170 | 300 | 0-10 | 170 | 55+75 |

| CSTMG – 4G10-200 | 300 | 0-10 | 200 | 75+90 |

| CSTMG – 4G10-250 | 300 | 0-10 | 250 | 90+110 |

| CSTMG – 4G10-300 | 300 | 0-10 | 300 | 2×110 |

| CSTMG – 4G10-350 | 300 | 0-10 | 350 | 110+132 |

| CSTMG – 4G10-400 | 300 | 0-10 | 400 | 2×160 |

| CSTMG – 4G10-450 | 300 | 0-10 | 450 | 160+185 |

| CSTMG – 4G10-500 | 300 | 0-10 | 500 | 185+200 |

| CSTMG – 4G10-550 | 300 | 0-10 | 550 | 2×200 |

| CSTMG – 4G10-600 | 300 | 0-10 | 600 | 2×250 |

| CSTMG – 4G10-650 | 300 | 0-10 | 650 | 250+280 |

| CSTMG – 4G10-700 | 300 | 0-10 | 700 | 2×280 |

| CSTMG – 4G10-800 | 300 | 0-10 | 800 | 280+315 |

CSTMG Four Roll Crusher Worldwide Cases

CSTMG Four Roll Crusher in Mongolia

CSTMG Quad Crusher Operates in Iran

CSTMG Four Roller Crusher Works in Indonesia

Four Roll Crusher Handling Materials

CSTMG four roll crusher is engineered for versatility, efficiently processing a wide spectrum of medium-hard materials critical to industrial operations.

Coal and Carbon-Based Materials. This crusher excels in processing coal, coal gangue, and petroleum coke. It is ideal for fuel preparation and handling industrial carbon by-products like filter cake with high efficiency and minimal clogging.

Minerals and Industrial Raw Materials. It is highly effective for crushing minerals like limestone, shale, and bauxite. The machine also processes various ores and industrial materials such as slag and phosphate rock for diverse production needs.

Key Material Specifications. The crusher is designed for materials with a feed size ≤300mm and compressive strength ≤120 MPa. This ensures optimal reduction ratios and reliable operation. It can handle materials with moderate moisture content effectively.

CSTMG Four Roll Crusher Working Principle

Our four-teethed roll crusher utilizes two stages of crushing within a single, compact unit to achieve efficient size reduction. Its operation is based on compression and shear forces generated by two pairs of counter-rotating rolls.

1. Material Feeding and Initial Crushing. The process begins when raw material is fed into the top of the crusher’s chamber. The material is immediately drawn into the gap between the first pair of counter-rotating rolls. These primary rolls, which are set farther apart, function as the primary crushing stage. They use powerful compressive force to break down large lumps of feed material into smaller, more manageable pieces.

Primary Crushing Stage: The top two rolls are set with a larger gap and often feature larger teeth or corrugations. Their primary function is to break down large feed material (up to 300mm) into a coarse-to-medium product through powerful compression and shear.

2. Intermediate Crushing and Final Sizing. The pre-crushed material then falls by gravity into the second crushing zone directly below. Here, the second pair of counter-rotating rolls, set much closer together, acts as the secondary crushing stage. This stage performs the final sizing of the material, applying further compressive and shear forces to reduce the particles to the precise, smaller product size required (e.g., under 10mm).

Secondary Crushing Stage: The bottom two rolls are set with a narrower gap and often have a different tooth profile. They are responsible for the final sizing of the material, ensuring a consistent and well-controlled output product with minimal fines.

3. Product Discharge. Once the material has passed through both crushing stages and meets the desired size specification, it exits the crusher through the discharge opening at the bottom. The entire process—from initial feed to final product—is continuous, ensuring high throughput and operational efficiency.

CSTMG Quad Roll Crusher Application Industry

Coal Processing Applications

Four roll crushers deliver exceptional performance in coal processing operations, providing precise size reduction for various coal-related applications. The machines efficiently handle run-of-mine coal, coal gangue, and filter cakes, reducing materials from ≤300mm to under 10mm in a single pass. This capability makes them ideal for coal preparation plants, power generation facilities, and coking operations where consistent particle size distribution is crucial for optimal combustion efficiency and downstream processing performance.

- Coal Preparation Plants. In coal preparation plants, the four-toothed roll crusher is used to crush raw coal extracted from mines, ensuring the coal particle size meets the requirements of subsequent washing processes. Through crushing, the contact area between coal and washing reagents is increased, thereby improving washing efficiency and clean coal recovery rates. For instance, after lump coal is crushed to an appropriate size, it becomes more conducive to separation in washing equipment such as jigging machines and heavy-medium cyclones, effectively separating clean coal, middlings, and gangue.

- Power Generation Facilities. These crushers provide uniform fuel sizing for combustion efficiency, reducing unburned carbon and emissions while maximizing energy output in thermal power plants.

- Coke Production Plants. The precise crushing action delivers consistently graded coal blends essential for high-quality metallurgical coke production in steel manufacturing processes.

Power Industry

Optimizing combustion efficiency is critical in power generation, and four-roll crushers play a key role in fuel preparation for thermal power plants. These robust machines deliver precisely sized coal and biomass fuels—including wood and straw—ensuring complete combustion and maximum energy output. Their ability to handle diverse fuel types makes them invaluable for improving operational efficiency in both conventional and renewable power generation facilities.

Mining and Mineral Processing

In mining operations, four roll crushers offer reliable size reduction for various ores and minerals. Their high reduction ratio and controlled crushing action make them suitable for both primary and secondary crushing stages. The machines effectively process metallic ores, industrial minerals, and aggregate materials, producing well-shaped particles with minimal fines generation. This capability supports efficient mineral liberation and improves downstream processing efficiency in concentrators and processing plants.

- Metallic Ore Processing. The four-roll crusher is employed in metal mining operations—including iron, copper, and lead-zinc ores—for primary or secondary crushing of run-of-mine material. In iron ore beneficiation plants, for instance, the crusher performs initial size reduction of the extracted ore, which then proceeds to downstream processes like grinding, magnetic separation, and flotation to recover valuable minerals such as iron concentrate.

- Industrial Minerals Production. The four-roll crusher processes non-metallic minerals—including limestone, dolomite, and gypsum—to precise particle sizes required for various industrial applications. Crushed limestone, for instance, is used in cement and lime production, or as a flux in metallurgical processes.

- Aggregate Manufacturing. The crushers produce well-graded, cubical aggregates essential for high-quality concrete and asphalt production in construction projects.

Building Materials Industry

The building materials sector benefits significantly from four roll crusher technology, particularly in raw material preparation for cement, glass, and ceramic production. The machines process limestone, clay, shale, and other raw materials with high efficiency and consistent output quality. Their ability to produce uniform particle size distribution ensures optimal raw meal quality for cement production and precise material specifications for glass manufacturing, ultimately enhancing final product quality and production efficiency.

- Cement Raw Material Preparation. Four roll crushers ensure optimal raw meal quality by providing precisely sized limestone and additives for efficient clinker production and quality control.

- Glass Manufacturing. These crushers deliver accurately sized quartz sand and feldspar, ensuring consistent melting characteristics and high-quality glass production in manufacturing facilities.

- Ceramic Production. The controlled crushing action provides uniformly sized raw materials essential for consistent ceramic product quality and manufacturing efficiency.

Recycling and Environmental Applications

Four roll crushers play a crucial role in recycling operations, processing construction waste, industrial by-products, and various recyclable materials. Their robust construction and versatile crushing action make them ideal for handling diverse materials, including demolition waste, slag, and other industrial residues. The machines contribute to sustainable resource utilization by converting waste materials into valuable secondary raw materials, supporting circular economy initiatives across multiple industries.

- Construction Waste Recycling. Four roll crushers efficiently process concrete, bricks, and demolition waste into reusable aggregates, supporting sustainable construction practices and resource conservation.

- Industrial By-Product Processing. These crushers handle steel slag, fly ash, and other industrial residues, transforming waste materials into valuable products for various applications.

- Municipal Solid Waste Processing. The robust design processes municipal solid waste for resource recovery, supporting waste-to-energy and recycling initiatives in urban environments.

Chemical Industry

In chemical raw material processing, such as the crushing of phosphate rock and salt mines, the four-roll crusher can break these bulk raw materials into appropriate particle sizes to facilitate subsequent process operations like chemical reactions and purification. For example, after phosphate rock is crushed, it can make better contact with reagents such as sulfuric acid, improving reaction efficiency and producing chemical products like phosphoric acid and phosphate fertilizers.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.