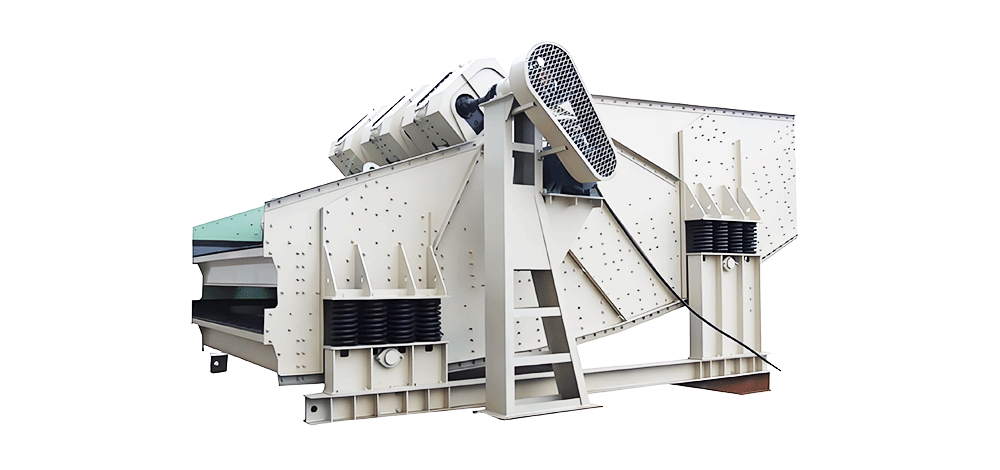

Flip Flow Screen

CSTMG flip flow screen is an advanced screening solution designed for difficult-to-process materials like wet, sticky, or fine particles. Its flexible polyurethane screen mats create a dynamic flipping motion, preventing clogging and ensuring high efficiency. Ideal for coal, aggregates, and recycling industries, it offers superior screening accuracy, minimal maintenance, and long service life. With robust construction and customizable configurations, the CSTMG flip flow screen delivers reliable performance in demanding applications.

APPLICATIONS

Coal

Mining

Fertilizer

CSTMG Flip Flow Screen Features

High Screening Efficiency. Elastic screen panels generate intense vibrations, ensuring rapid material separation with minimal energy loss.

Anti-Clogging Design. Dynamic flexing motion prevents material buildup, eliminating blockages even with sticky, wet substances.

Wide Material Adaptability. Handles wet, sticky, or fine materials effortlessly, outperforming rigid screens in challenging conditions.

Precise Size Separation. Sharp particle sorting reduces oversize/undersize errors for consistent product quality.

Gentle Material Handling. Reduces particle degradation compared to rigid screens, preserving fragile granule integrity.

CSTMG Flip Flow Screen Specification

| Mechanical Flip Flow Screen | |||||||

| Model | Screen Plate | Max. Input Size | Capacity | Electrical Motor | |||

| Layer(s) | Area(m²) | Mesh Size(mm) | (mm) | (t/h) | Power(kw) | Qty(pcs) | |

| CSTMG – MFF2.0-6.30 | 1 | 12.6 | 3-13 | 80 | 150-400 | 22 | 1 |

| CSTMG – 2MFF2.0-6.30 | 2 | 12.6*2 | Upper:14-30 Lower: 3-13 | 80 | 350-650 | 37 | 1 |

| CSTMG – MFF2.2-7.56 | 1 | 16.6 | 3-13 | 80 | 250-500 | 37 | 1 |

| CSTMG – 2MFF2.2-7.56 | 2 | 16.6*2 | Upper:14-30 Lower: 3-13 | 80 | 450-750 | 45 | 1 |

| CSTMG – MFF2.2-8.82 | 1 | 19.4 | 3-13 | 80 | 250-600 | 37 | 1 |

| CSTMG – 2MFF2.2-8.82 | 2 | 19.4*2 | Upper:14-30 Lower: 3-13 | 80 | 500-900 | 45 | 1 |

| CSTMG – MFF2.6-8.82 | 1 | 22.9 | 3-13 | 100 | 350-750 | 37 | 1 |

| CSTMG – 2MFF2.6-8.82 | 2 | 22.9*2 | Upper:14-30 Lower: 3-13 | 100 | 650-1100 | 45 | 1 |

| CSTMG – MFF3.0-8.82 | 1 | 26.5 | 3-13 | 100 | 400-950 | 45 | 1 |

| CSTMG – 2MFF3.0-8.82 | 2 | 26.5*2 | Upper:14-30 Lower: 3-13 | 100 | 800-1400 | 75 | 1 |

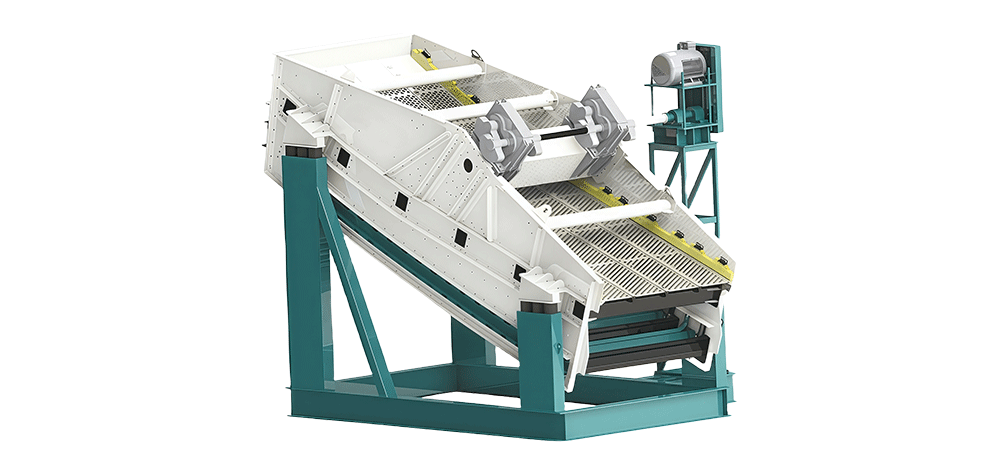

| Vibrating Flip Flow Screen | |||||||

| Model | Screen Plate | Max. Input Size | Capacity | Electrical Motor | |||

| Layer(s) | Area(m²) | Mesh Size(mm) | (mm) | (t/h) | Power(kw) | Qty(pcs) | |

| CSTMG – VFDB(SF)1861 | 1 | 10.98 | 0.5-8 | 80 | 100-300 | 22 | 1 |

| CSTMG – 2VFDB(SF)1861 | 2 | 10.98*2 | Upper:8-30 Lower: 0.5-8 | 80 | 200-400 | 30 | 1 |

| CSTMG – VFDB(SF)2461 | 1 | 14.64 | 0.5-8 | 80 | 150-400 | 37 | 1 |

| CSTMG – 2VFDB(SF)2461 | 2 | 14.64*2 | Upper:8-30 Lower: 0.5-8 | 80 | 300-500 | 45 | 1 |

| CSTMG – VFDB(SF)3061 | 1 | 18.3 | 0.5-8 | 100 | 200-600 | 45 | 1 |

| CSTMG – 2VFDB(SF)3061 | 2 | 18.3*2 | Upper:8-30 Lower: 0.5-8 | 100 | 300-650 | 55 | 1 |

| CSTMG – VFDB(SF)3685 | 1 | 30.6 | 0.5-8 | 100 | 300-800 | 55 | 1 |

| CSTMG – 2VFDB(SF)3685 | 2 | 30.6*2 | Upper:8-30 Lower: 0.5-8 | 100 | 500-1050 | 75 | 1 |

| CSTMG – VFDB(SF)43100 | 1 | 43 | 0.5-8 | 100 | 400-1000 | 75 | 1 |

| CSTMG – 2VFDB(SF)43100 | 2 | 43*2 | Upper:8-30 Lower: 0.5-8 | 100 | 660-1300 | 90 | 1 |

CSTMG Flip Flow Screen Worldwide Cases

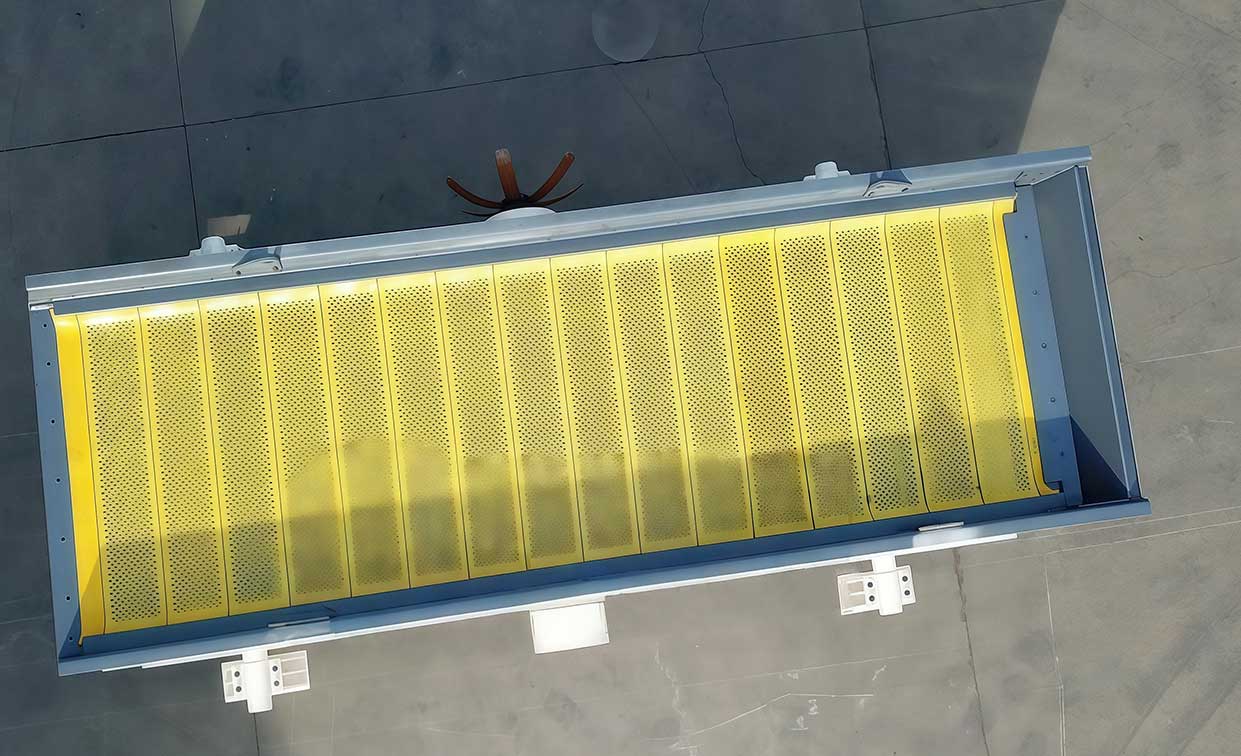

CSTMG Flip Flow Screen Ready to Be Sent to South Africa

CSTMG Flip Flow Screen Test For Our South African Customer

CSTMG Flip Flow Screen Test For Saudi Arabia Customer

Flip Flow Screen Handling Materials

Wet & Sticky Materials. Flip flow screens excel in handling high-moisture, adhesive materials like wet coal, sludge, and clay. The elastic screen panels stretch and contract, breaking material clumps while preventing clogging. Ideal for dewatering, washing, and classifying sticky ores or industrial byproducts with 15-30% moisture content.

Fine & Ultra-Fine Powders. Designed for particles below 10mm, including silica sand, fly ash, and mineral powders. The aggressive screen motion ensures precise separation without blinding, even for micron-grade materials. Common in cement, ceramics, and chemical industries where dry sieving fails.

Abrasive & Heavy-Duty Aggregates. Handles sharp, heavy materials like crushed stone, slag, and metal scraps. Polyurethane panels resist wear better than steel mesh, maintaining performance in mining and construction applications.

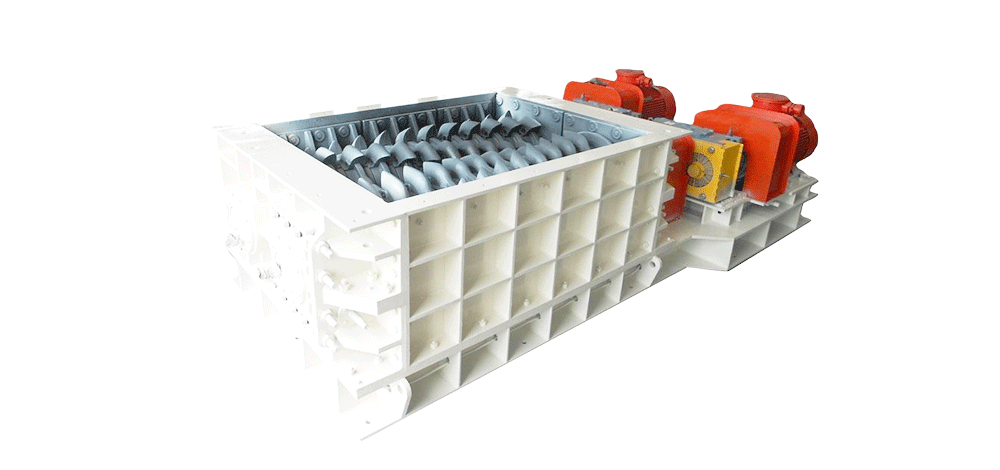

CSTMG Flip Flow Screen Production Details

Robust Modular Construction

- Interchangeable panels: Quick-release tensioning system allows fast screen media swaps (rubber, PU, or hybrid blends).

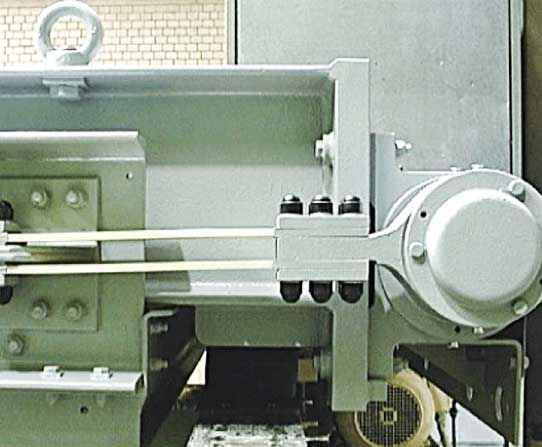

- Dual-motor drive: Synchronized vibrators ensure balanced force distribution, reducing structural stress.

- Sealed compartments: Optional dust/waterproof enclosures for hazardous or damp environments (e.g., chemical plants).

Dual-Action Screening Mechanism

- Flip flow screens use elastic polyurethane panels tensioned between rigid frames, driven by counter-rotating vibrators. The panels rapidly stretch (up to 1500 RPM) and relax, creating intense ”slingshot” motion that dislodges sticky particles and prevents blinding.

Adaptive Performance

- Adjustable frequency (12-25Hz), amplitude (5-15mm), and screen angle (0°-25°) to optimize throughput (1–500 t/h).

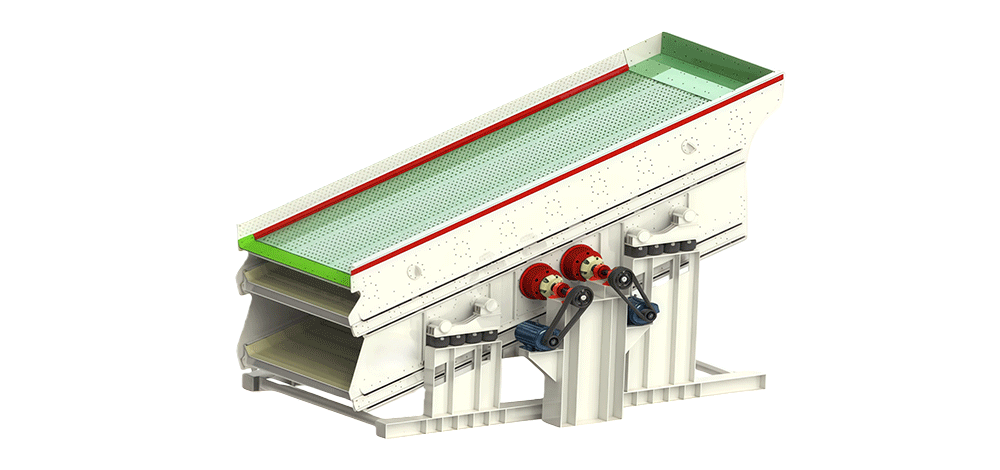

CSTMG Flip Flow Screen Working Principle

The flip flow screen operates through a unique dual-action mechanism that combines rigid frame vibration with flexible panel stretching. At the heart of the system are elastic polyurethane or rubber screen decks, which are tensioned between rigid frames and driven by counter-rotating vibrators. These synchronized motors generate opposing forces that stretch and relax the panels at high frequencies ranging from 12 to 25 Hz (700-1500 RPM), creating the screen’s distinctive dynamic motion.

During operation, the screen panels alternate between two distinct phases that enable efficient material separation. In the stretch phase, the panels are pulled taut to form a flat surface that propels material forward, while in the relax phase, they snap back into a wavy shape that violently agitates the material. This continuous stretching and relaxing action produces powerful shear forces that break apart material clumps, dislodge fine particles trapped in sticky masses, and prevent blinding by actively clearing sieve openings. The motion is particularly effective at maintaining screen aperture clarity, working up to three times faster than conventional rigid screens at preventing clogging.

The screening process achieves separation through forced stratification and active sieving. As material moves across the screen surface, coarse particles ride the wave-like motion to the discharge end, while fine particles are pushed through screen apertures during the panel tensioning phase. This mechanism allows the flip flow screen to handle challenging materials with moisture content up to 35%, including difficult-to-process substances like coal slurry and iron ore fines. The focused panel movement not only improves screening efficiency but also reduces energy consumption by 20-30% compared to conventional screens, making it both a high-performance and energy-efficient solution for demanding screening applications in mining, recycling, and aggregate industries.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.