CSTMG Flip Flow Screen Successfully Working in South Africa For Coal Processing

Client: Leading Coal Mining Operator, Mpumalanga Province, South Africa

Challenge: Traditional screens were failing to efficiently separate wet, sticky coal fines (0-6mm), causing:

- 22% material carryover to waste streams

- Frequent screen blinding and downtime (3-4 unplanned stops/week)

- Throughput limited to 80t/h despite 120t/h design capacity

CSTMG Solution:

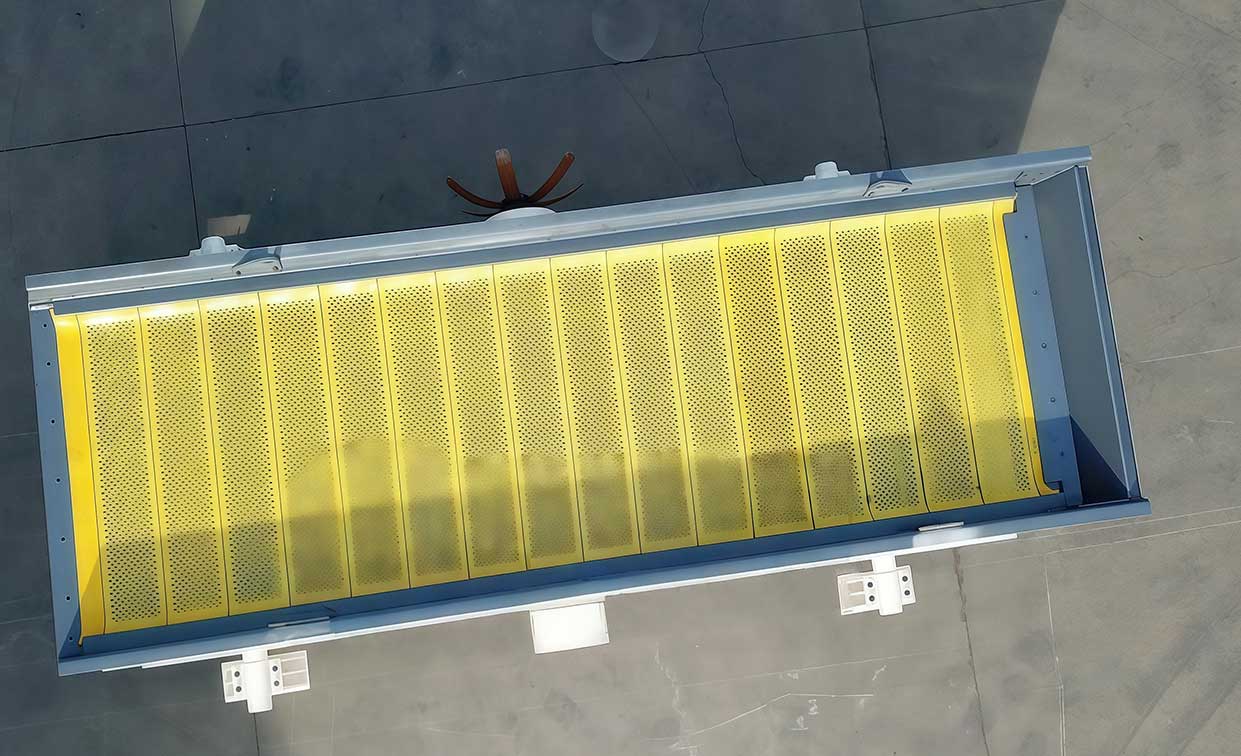

- Flip Flow Screen Model: Mechanical flip flow type (2.4m x 6m) with:

- Polyurethane screen mats (10mm aperture)

- Dual-mass vibration system (50Hz, 8mm amplitude)

- IP66-rated motors for high humidity operation

- Key Adaptations:

- Corrosion-resistant SS304 side plates for acidic coal slurry

- Integrated spray bars for continuous mat cleaning

- Remote vibration monitoring via CSTMG IoT platform

Results (12 Months Post-Installation):

✔ Throughput Increased 53% to 122t/h (exceeding design capacity)

✔ Material Loss Reduced from 22% to 3.8% – recovering 8,400 tons/month of salable fines

✔ Maintenance Downtime Cut 80% – now <4 hours/month

✔ ROI Achieved in 7 Months through increased production and reduced waste

Client Testimonial:

“The CSTMG flip flow screen fundamentally changed our fines processing. We’ve expanded the solution to three additional plants and are seeing consistent 40%+ efficiency gains.”

— Odirile Motasi, South Africa