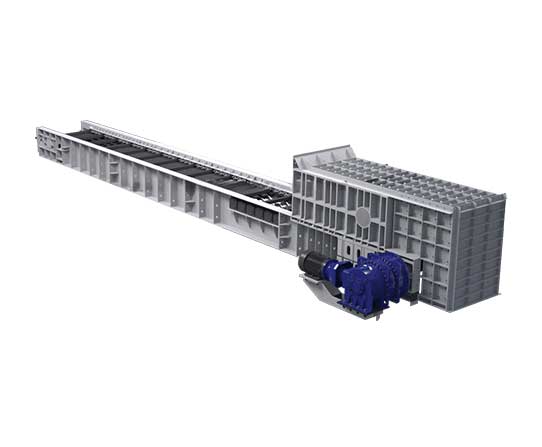

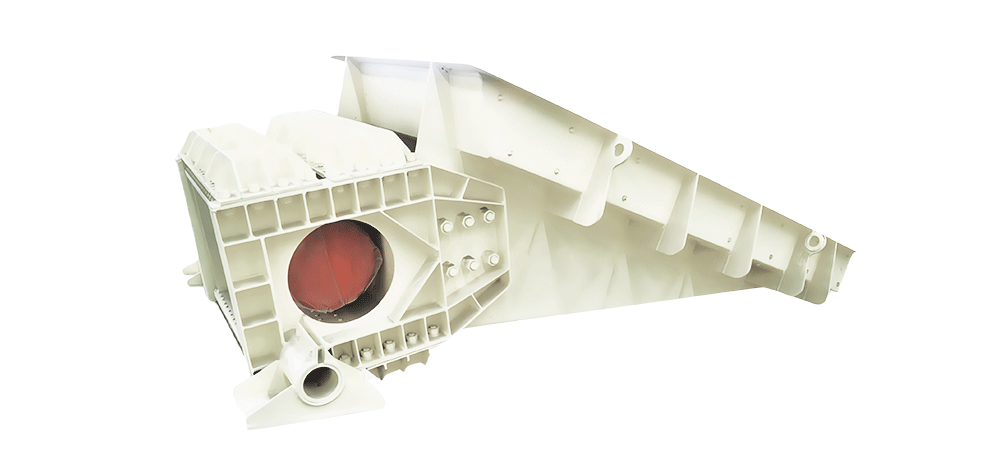

Feeder Breaker

CSTMG feeder breaker is a rugged mining machine that combines material feeding and primary crushing in one unit. It receives raw coal or ore from haulage systems, sizes it through a crushing mechanism, and delivers it evenly to conveyors. Designed for underground and surface mines, it handles high-capacity loads (up to 5,000 t/h) while reducing dust and fines. Key features include adjustable crushing rolls, heavy-duty chains, and overload protection, ensuring continuous operation in harsh mining conditions.

APPLICATIONS

Coal

Mining

CSTMG Feeder Breaker Features

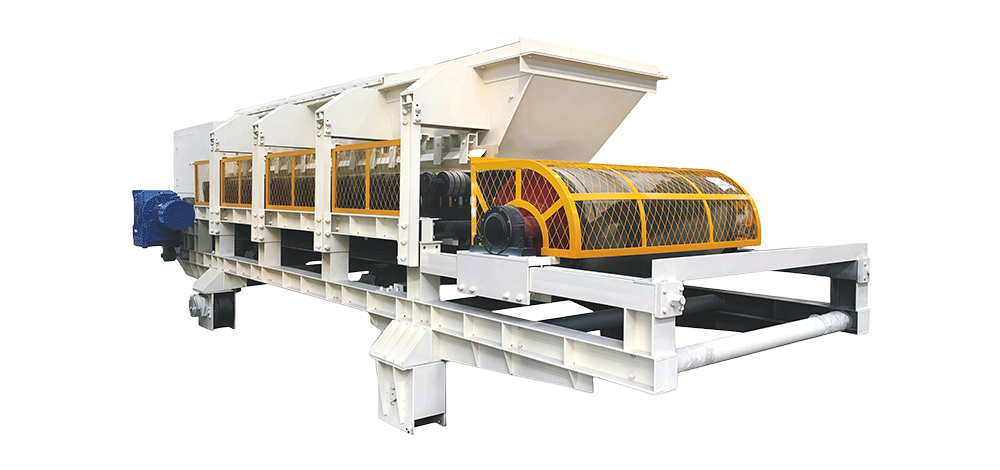

Integrated Feeding & Crushing. Combines material transport and size reduction in one unit, eliminating the need for separate feeders and crushers. Handles raw coal/ore directly from haulage systems.

Oversized Lump Handling. Accepts feed sizes up to 2,050×2,050mm, processing blasted ore or coal without pre-screening. Reduces primary crushing workload.

Pre-Screening System. Static/dynamic grizzly separates fines before crushing, minimizing over-processing. Improves product quality and reduces energy waste.

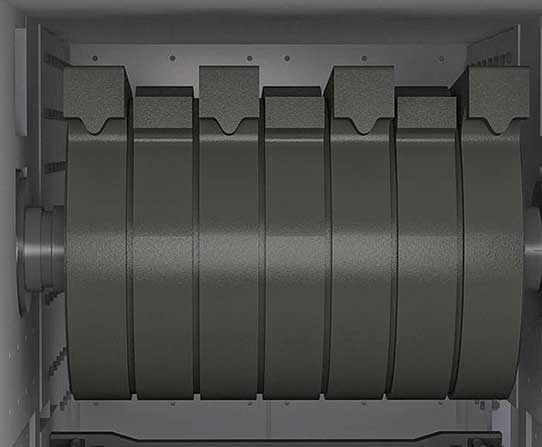

Adjustable Crushing Roll. Helical tooth rolls provide controlled fragmentation (95% under 200mm). Replaceable alloy teeth extend service life in abrasive conditions.

CSTMG Feeder Breaker Specification

| Model | Conveyor Width(mm) | Conveyor Length(m) | Max. Material Input Size(mm) | Nominal Material Output Size(mm) | Handling Capacity(t/h) |

| TP1400 | 1,350 | 6-20 | 800×800 | ≤200 | 500-1,000 |

| TP1600 | 1,550 | 8-25 | 1,000×1,000 | ≤300 | 800-1,400 |

| TP1800 | 1,750 | 8-30 | 1,200×1,200 | ≤300 | 1,200-2,000 |

| TP2200 | 2,150 | 8-30 | 1,500×1,500 | ≤400 | 1,500-3,000 |

| TP2400 | 2350 | 10-30 | 1,750×1,750 | ≤500 | 2,000-4,000 |

| TP2800 | 2750 | 10-30 | 2,050×2,050 | ≤500 | 3,000-5,000 |

CSTMG Feeder Breaker Worldwide Cases

CSTMG Feeder Breaker Delivered to Türkiye

CSTMG Feeder Breaker Works in Indonesia

CSTMG Feeder Breaker Operates in Rwanda

Feeder Breaker Handling Materials

Metal Ores. Feeder breakers excel in processing metal ores such as iron ore (magnetite, hematite), copper ore (chalcopyrite, bornite), and lead-zinc ore.

Non-Metallic Minerals. In non-metallic mineral applications, feeder breakers handle coal (thermal and coking), limestone, gypsum, and potash. They crush raw coal (≤1500mm) to ≤100mm, integrating pre-screening to bypass fines and improve washing plant efficiency.

Industrial Byproducts. Feeder breakers efficiently process industrial byproducts like coal rejects (slate, shale) and oil sands.

Specialty Applications. Specialty uses include processing diamond-bearing kimberlite and phosphate rock.

CSTMG Feeder Breaker Production Details

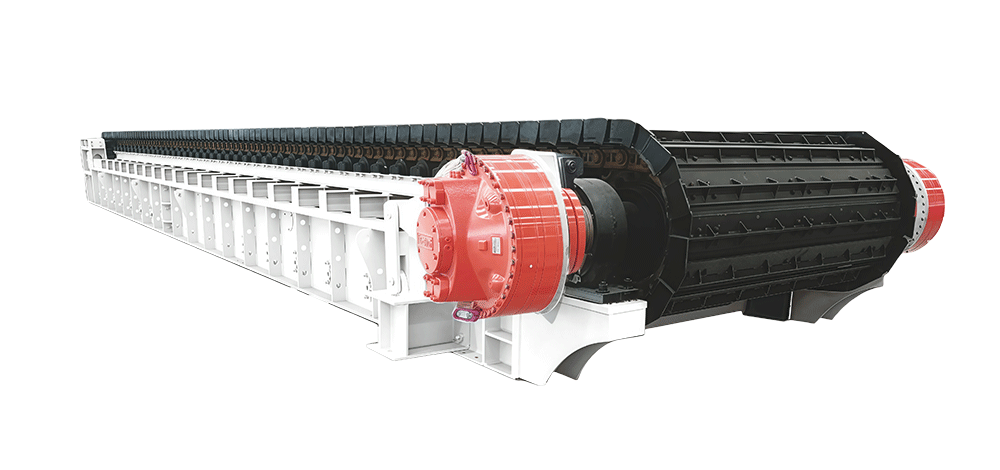

Flexible Crushing Unit

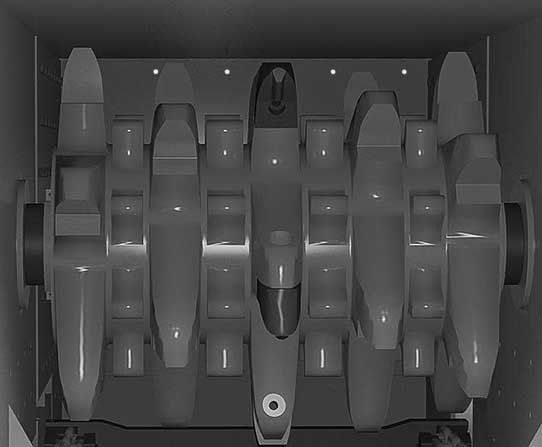

- Dual Crushing Options: Toothed Roll Crusher: Hardened alloy steel teeth (HRC 58-62) apply “strike-and-stretch” action, producing uniform 95% <200mm output for metallurgical coal or iron ore. Hammer Crusher: Hydraulic-adjustable hammers handle oversized lumps (≤2000mm), ideal for limestone or oil sands. Quick-release hammers allow replacement in <30 minutes.

- Modular Wear Parts: Crusher teeth/hammers use bolt-on design for single-component replacement, cutting downtime by 70% versus welded alternatives.

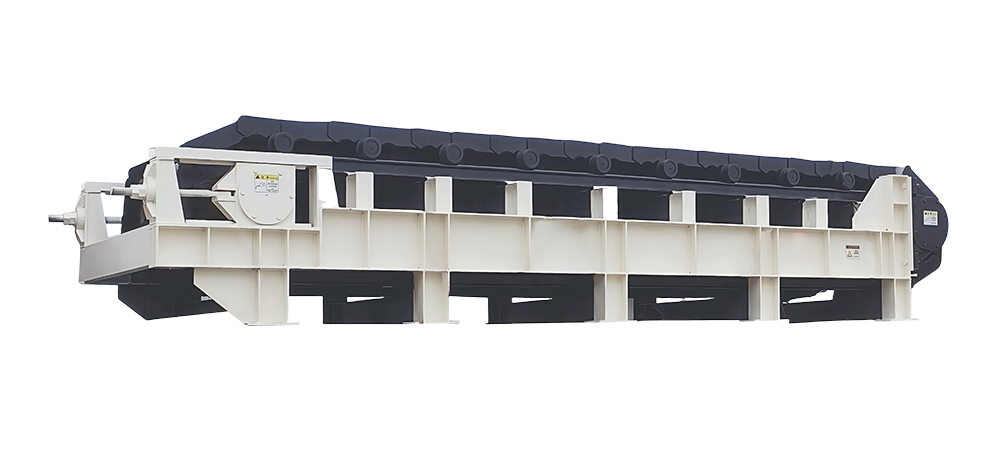

Reinforced Conveying System

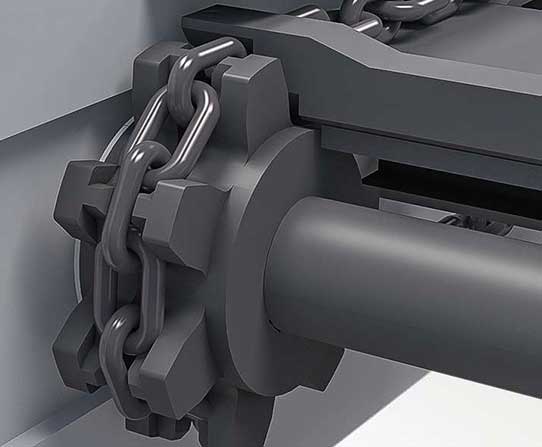

- Mine-Grade Chains: ISO 1977-standard round-link chains with sealed rollers endure 300kN tensile loads, outperforming conventional chains by 3x in underground coal mines.

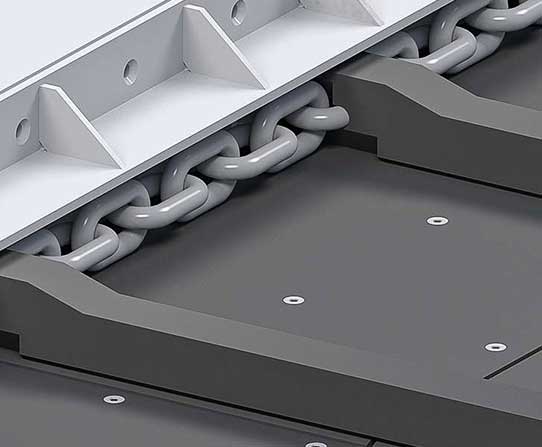

- Wear-Resistant Pans: 30-60mm thick NM400 steel pans with replaceable liners (200-400 Brinell) withstand abrasive iron ore or copper slag.

- Auto-Tensioning: Hydraulic tensioners maintain optimal chain tightness, preventing slippage even with 5000t/h throughput.

CSTMG Feeder Breaker Working Principle

Raw materials such as blasted ore or coal are loaded into the hopper, where heavy-duty chains with flight bars transport them toward the crushing zone at controlled speeds. A pre-screening grizzly separates fines to bypass unnecessary crushing, reducing energy consumption and wear on components.

In the crushing stage, the material is processed by either a toothed roll crusher or a hammer crusher. The toothed roll crusher utilizes spiral-mounted alloy teeth to fracture large lumps into uniform fragments, while the hammer crusher employs hydraulically adjustable hammers for pulverizing oversized material. Both systems are designed for quick maintenance, with modular components allowing for efficient replacements.

Crushed material exits through an adjustable discharge gate, ready for further processing. The system incorporates smart monitoring, with sensors tracking chain tension, bearing temperature, and wear patterns. Variable frequency drives regulate chain speed to match downstream demand, ensuring optimal throughput.

Related Products

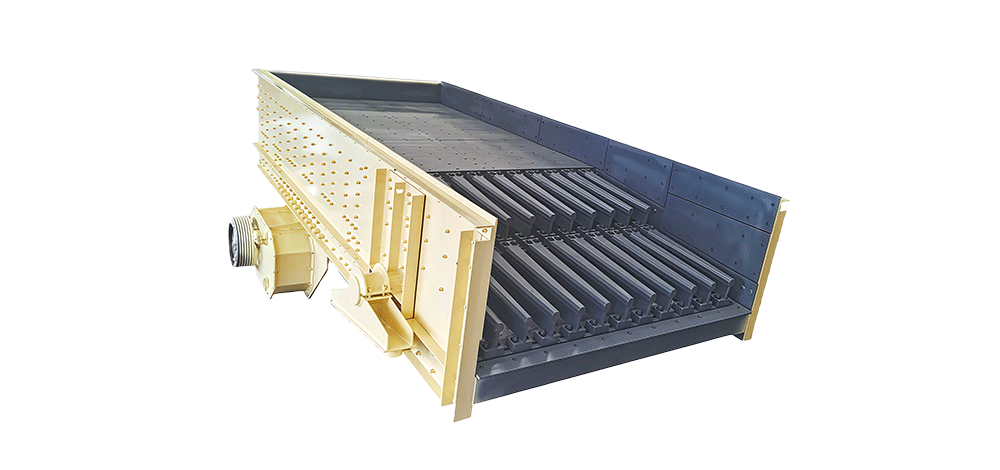

BWJ Apron Feeder

ZBWJ Apron Feeder

Armored Belt Feeder

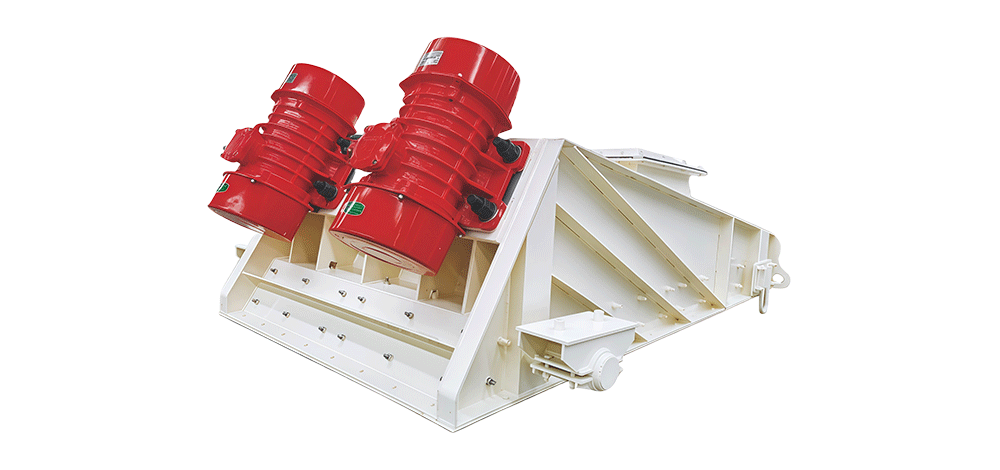

Double Mass Vibrating Feeder

MZG Vibrating Screen

ZSW Vibrating Feeder

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.