Coal Crushing Plant

CSTMG coal crushing plant delivers high-efficiency, low-maintenance coal processing. Our robust system features mineral sizers, crushers, and screens for optimal size reduction with 30% lower energy use. Designed for wet/sticky coal, it minimizes clogging and dust. Modular design enables fast deployment, while smart controls optimize output. Trusted in harsh mining conditions (-30°C to 50°C), our plants boost productivity while cutting costs.

Hot Mining Crushing and Screening Equipment

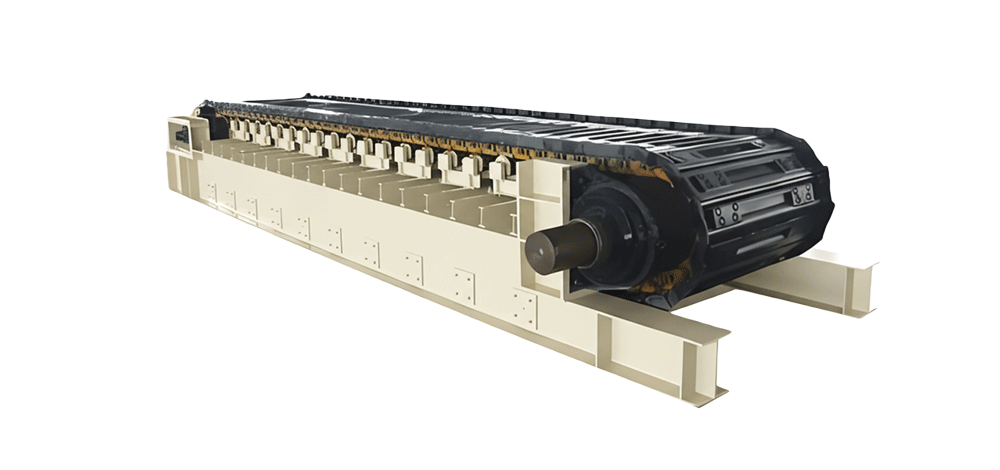

Apron Feeder

Length (m): 2-20

Capacity (m³/h): 50-4,000

Max feeding size (mm): 350-1,800

Feeder Breaker

Capacity (t/h): 500-5,000

Conveyor length (m): 6-30

Conveyor width (mm): 1,350-2,750

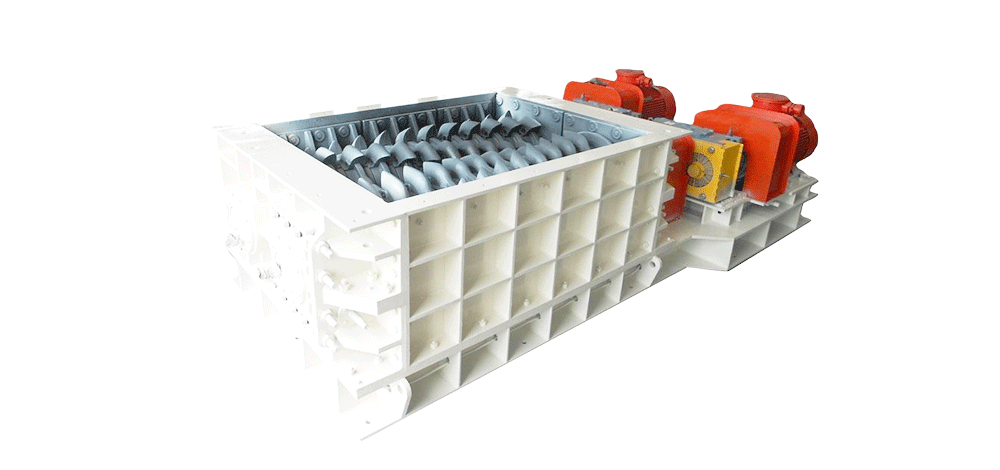

Mineral Sizer

Output size (mm): 50-300

Capacity (t/h): 250-10,000

Max feed size(mm): 200-1,500

Mobile Crusher Plant

Capacity (t/h): 5-1,000

Feeding Size (mm): 0-350

Type: Crawler/Wheeled

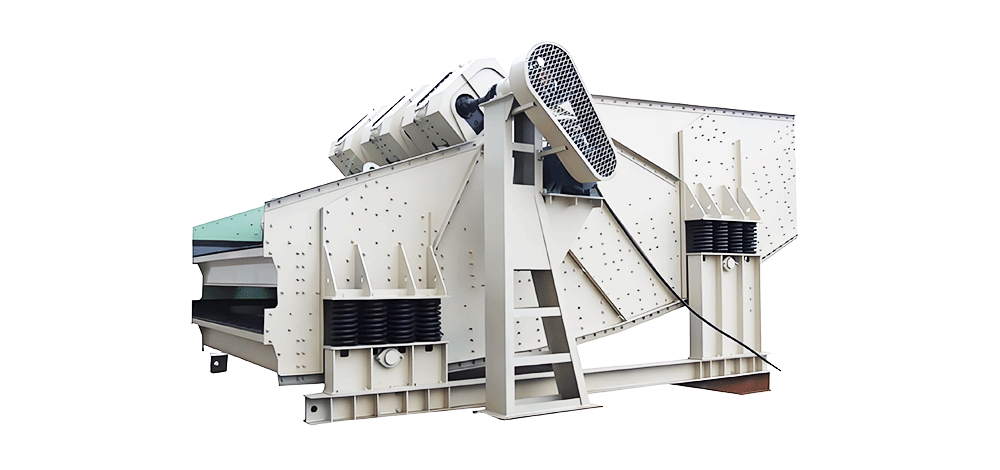

Banana Screen

Capacity (t/h): 50-2,500

Max. Screen Width (mm): 4,300

Max. Screen Length (mm): 8,500

Roller Screen

Capacity (t/h): 150-1,800

Screen Width (mm): 1,200-2,400

Graded Particle Size (mm): 10-100

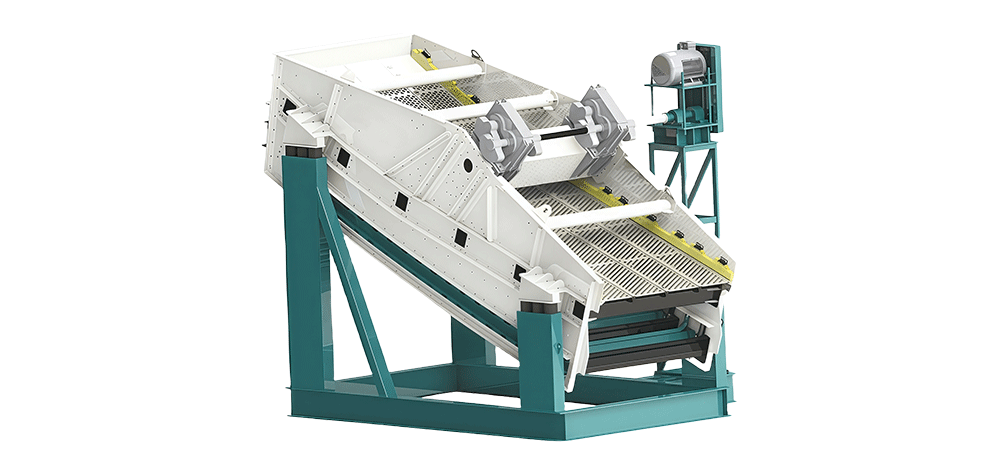

Flip Flow Screen

Capacity (t/h): 150-1,400

Feed size (mm): ≤80-≤100

Type: Mechanical/Vibrating

Circular Vibrating Screen

Number of Layers: 2-3

Capacity (t/h): 60-1,500

Max Input Size (mm): 200

Linear Vibrating Screen

Number of Layers: 1-2

Capacity (t/h): 40-950

Max Input Size (mm): 100

Jaw Crusher

Output size (mm): 70-300

Capacity (t/h): 130-1,150

Max feed size(mm): 560-960

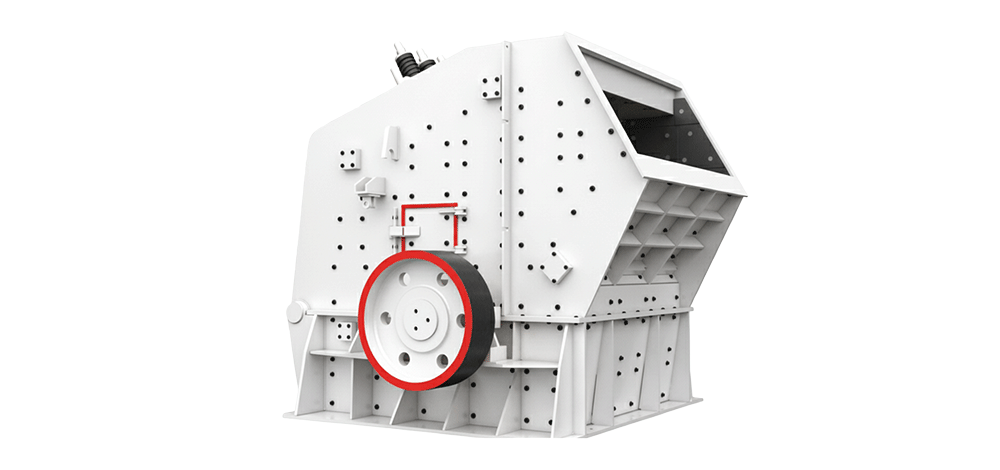

Impact Crusher

Rotor dia (mm): 1,300-1,600

Capacity (t/h): 300-1,000

Max feed size(mm): 600-800

Cone Crusher

Capacity (t/h): 27-1,270

Min. discharge size (mm): 9-38

Type: Single / Multi Cylinder

Hammer Crusher

Rotor dia (mm): 1,600-3,000

Capacity (t/h): 200-5,500

Max feed size(mm): ≤700-≤1,100

VSI Crusher

Capacity (t/h): 120-520

Soft material max. feed size (mm): 35-60

Hard material max. feed size (mm): 30-50

CSTMG Coal Crushing Plant Structure

CSTMG’s coal crushing plants feature a robust, modular structure designed for maximum productivity even in harsh mining conditions. The system integrates primary crushing with mineral sizers or jaw crushers, secondary/tertiary crushing using roll or impact crushers, and efficient screening with banana screens – all connected by heavy-duty apron feeders and corrosion-resistant conveyors. Our intelligent PLC control center enables real-time monitoring and remote diagnostics.

Available in customized configurations for underground or open-pit operations, our plants handle everything from high-sulfur coal to mobile installations with optimal efficiency.

Feeding

Our advanced feeding system delivers precise material control through heavy-duty apron or belt feeders, featuring impact-resistant Hardox 400 pans, hydraulic tensioning for alignment stability, and dust-proof skirtboards with replaceable seals. Our smart load sensors prevent overfeeding while optional configurations include vibrating feeders for sticky materials, heat-resistant designs for hot clinker, and explosion-proof motors for coal operations.

Types of Feeding Equipment

Crushing

CSTMG coal crushing system features dual-stage crushing with mineral sizers (primary) and hammer crushers (secondary), achieving 0-50mm output at 500-3000tph. Includes anti-clogging teeth, dust-proof enclosures, and VFD drives for energy savings. Designed for high-moisture coal with <5% fines generation. Optional pre-screening and smart load control available.

Types of Crushing Equipment

Screening

CSTMG coal screening system utilizes banana screens (other screening equipment optional) with polyurethane decks for high-efficiency 0-50mm classification at 3000tph. Features 25° adjustable slope, non-clogging design, and dust-tight enclosures. Includes smart vibration monitoring and quick-release tensioners for <30min panel replacement.

Types of Screening Equipment

Conveying

CSTMG conveying system integrates heavy-duty belt conveyors, drive units, and self-aligning rollers for efficient material transport. Features V-grooved drive drums, impact-resistant idlers, and polyurethane cleaners to ensure smooth operation. Designed for high-capacity coal handling with dust-proof skirts and rip detection. Optional arctic-grade and fire-resistant configurations available.

Types of Conveying Equipment

Coal Crushing Output

CSTMG delivers fully customized coal crushing plants tailored to your exact production needs. Our engineered solutions adapt to your specific coal characteristics—whether processing high-moisture lignite, abrasive anthracite, or sulfur-rich thermal coal. We precisely configure each crushing stage (primary sizers, secondary roll crushers, and tertiary impactors) to achieve your target output size, while minimizing fines generation.

Intelligent automation ensures optimal throughput with real-time particle size monitoring. From compact modular designs for space-constrained sites to heavy-duty plants for mega mines, we integrate dust suppression, explosion-proofing, and energy recovery systems.

Coarse Coal

Mid-Size Coal

Fine Coal

Coal Powder

Application Industry

Advantages

As an industry leader with 60+ patents and ISO 9001 certification, CSTMG combines cutting-edge engineering with decades of mining expertise to deliver superior coal crushing solutions.

Our plants feature high-efficiency mineral sizers and smart automation, ensuring precise output sizing with <5% fines generation and throughput up to 5,000 TPH. Designed for harsh conditions, they incorporate tungsten carbide teeth (3x longer wear life), dust-proof enclosures, and arctic/desert packages (-40°C to 50°C). With 30% lower energy use and remote monitoring, we maximize uptime while minimizing costs.

CSTMG Global Cases

Coal Crusher Plant Works in Indonesia

Crushing and Screening Plant Works in Namibia

CSTMG Crushing Plant Operates in Fiji

Ultimate Coal Crusher Comparison Guide

| Jaw Crusher | Cone Crusher | Hammer Crusher | Mineral Sizer | Four Roll Crusher | Mobile Crusher | |

| Core Function | Primary Crushing Dealing with hard rock & heavy gangue. | Secondary/Tertiary Processing hard gangue stones. | One-Step Crushing Primary & Secondary combined. | Sizing / Primary Designed specifically for coal. | Fine Crushing Strict particle size control. | Flexible Crushing Pit-side operations. |

| Working Principle | Compression Moving jaw presses against stationary jaw (Chewing). | Lamination/Compression Mantle rotates within the concave (Grinding). | Impact High-speed hammers strike the material. | Shear & Tension Low speed, high torque tooth rollers (Cutting). | Double Compression 4 rollers create a 2-stage crushing process. | Integrated System Host crusher mounted on tracks/tires. |

| Capacity | 100 – 1500 TPH | 50 – 1000 TPH | 50 – 3000 TPH | 200 – 10,000 TPH (High Throughput) | 50 – 400 TPH | 50 – 800 TPH |

| Feed Size | Max 1200mm | Max 300mm | Max 1600mm | Max 1500mm | Max 100mm (Usually <50mm) | Depends on host unit |

| Output Size | 100 – 300mm | 10 – 50mm | < 30mm (Adjustable) | 50 – 300mm (Uniform Cubes) | < 3 – 10mm (Precise) | Depends on host unit |

| Pros for Coal | Simple structure; Handles extremely hard/large gangue rocks well. | Wear parts are durable against abrasive gangue. | High reduction ratio; Low initial capital cost. | Handles Wet/Sticky Coal; Lowest Fines (<5%); Compact & Energy Efficient. | Extremely uniform output; Minimal dust/fines; Perfect for specific boiler specs. | Eliminates trucking costs; Fast setup; Goes directly to the coal face. |

| Cons for Coal | Poor Particle Shape (Flaky); Blocks easily with wet coal; Low throughput for size. | High Fines Generation (Profit loss); Clogs with soft coal; Poor for sticky material. | Excessive Fines (Pulverizes coal); High wear on hammers; | Higher initial purchase cost | Lower capacity | Higher initial purchase cost |

| Best For | Open-Pit Mines with high rock content (Gangue >30%); Primary crushing of dry or standard ROM coal. | Aggregate Lines turning coal waste (gangue) into construction gravel. | Power Plants (Thermal) where coal is pulverized anyway & budget is tight; Secondary/Tertiary crushing of medium-hard coal, simplified flow. | Modern CHPPs & Washeries Primary crushing of high-moisture, sticky, or high-clay content run-of-mine coal. | CFB Boilers / Chemical Plants Secondary/Tertiary crushing where product uniformity and minimal fines are critical (e.g., thermal power plants). | Contract Crushing / Remote Pits Multi-site operations to cut down raw coal transport costs; Short-term projects. |

Best Suitable Coal Crusher to Choose: From ROM to Boiler Feed

CSTMG offers full Engineering, Procurement, and Construction support to design a flowsheet tailored to your specific output requirements.

Stage 1: Primary Crushing (ROM Handling)

- Equipment: CSTMG Mineral Sizer (Double Toothed Roll Crusher)

- Function: Accepts large Run-of-Mine (ROM) lumps up to 1,500mm.

- Output: Reduces material to 150mm – 300mm for transport or secondary processing.

- Advantage: Includes a built-in “screening” effect. Material already small enough passes through the tooth gap immediately, increasing total throughput capacity (up to 14,000 t/h).

Stage 2: Secondary & Tertiary Crushing (Precision Sizing)

- Equipment: CSTMG Four Roll Crusher

- Function: The ultimate solution for final product sizing. It features a “One Feed, Two Crushing” design—upper rollers handle coarse crushing, while lower rollers handle fine crushing.

- Output: Precision control down to ≤10mm or ≤30mm (adjustable).

- Advantage: Perfect for CFB (Circulating Fluidized Bed) Boilers and pulverized coal preparation, ensuring strict granularity with no oversize particles.

Stationary vs Mobile Crushing Plants For Coal Handling Preparation Plant

| Stationary Crushing Plant (Fixed Line) | Mobile Crushing Plant (Track/Wheel) | |

| Definition | A permanent facility built on concrete foundations, usually integrated with a washing/preparation plant. | A compact crushing unit mounted on a crawler (track) or tire chassis, capable of moving directly to the coal face. |

| Crusher Types | Accommodates the largest crushers (e.g., very large primary Jaw Crushers or Mineral Sizers. | Typically houses medium-to-large crushers (Hammer Crusher, smaller Jaw, or Roll Crusher. |

| Setup & Installation | Slow (1-3 Months) Requires extensive civil works, concrete foundations, and steel structures. | Fast (1-4 Days) “Plug & Play.” Requires no civil works or permanent foundation. |

| Production Capacity | Unlimited (Scaleable) Can handle massive throughput (e.g., >2000 TPH). Ideal for “Super Mines.” | Limited Restricted by chassis size. Typically 50 – 800 TPH per unit. (Can combine multiple units). |

| Haulage Costs (Trucking) | High Trucks must haul ROM coal from the pit to the fixed plant (distance increases as mine expands). | Minimal The crusher moves to the coal. Crushed coal is conveyed out. Drastically reduces truck fleet costs. |

| Initial Investment (CAPEX) | Lower (Equipment Cost) Machines are cheaper, but construction/installation adds cost. | Higher (Equipment Cost) Integrated chassis, engines, and hydraulics make individual units more expensive. |

| Operational Cost (OPEX) | Lowest Long-Term Grid electricity is cheaper than diesel; maintenance access is easier; fewer specialized technicians needed. | Higher Diesel fuel consumption (unless hybrid); higher wear on undercarriage. |

| Environmental Impact | Contained Easier to enclose (dust covers) and install permanent dust suppression systems. | Higher Exposure Dust and noise are generated right at the mining face (though CSTMG units have suppression systems). |

| Flexibility | Zero Once built, it cannot move. | Maximum Can easily move to a new bench, a new pit, or be resold/rented out after the project ends. |

| Maintenance | Easy Access Walkways, platforms, and cranes make servicing safe and fast. | Restricted Compact design makes accessing internal components slightly more difficult. |

| Best For | Long-Life Mines (>10 Years) Large-scale CHPPs where coal washing and precise screening are required centrally. | Contract Mining / Short-Life Pits Remote areas, early production phases, or reducing truck haulage distance. |

How to Handle Wet & Sticky Coal Without Clogging?

In the competitive coal mining and processing industry, the efficiency of your crushing plant directly dictates your profitability. Whether you are operating an open-pit mine, a coal washing plant, or a thermal power station, the challenge remains the same: How do you process high volumes of coal, often wet and mixed with gangue, without clogging your machines or turning valuable lump coal into waste dust?

Unlike traditional hammer mills or jaw crushers that rely on brute force and high energy consumption, our Coal Crushing Plants utilize advanced Shear-Force Technology. We design and build complete crushing circuits centered around our flagship Mineral Sizers (Double Toothed Roll Crushers) and Four Roll Crushers, ensuring you get the exact particle size you need with minimum operational costs.

CSTMG Roll Crushers operate on a low-speed, high-torque principle. Our specialized tooth profiles grip the material and apply tension and shear forces—breaking the coal along its natural cleavage lines.

If your mine deals with rain-soaked raw coal, lignite, or material with high clay content, you know the nightmare of equipment blockage.

CSTMG Coal Crushing Plants are specifically engineered to be clog-proof., and our plants are proven to produce a uniform, cubical product with 50-70% less fines than traditional crushers.

- No Bottom Screen: Unlike hammer mills, our Mineral Sizers have no bottom screen to get blocked. The gap between the rollers determines the sizing.

- Self-Cleaning Mechanism: The intermeshing rotation of the toothed rollers creates a natural self-cleaning effect. For extreme conditions, we install adjustable scrapers that actively peel sticky material off the roller surface with every rotation.

- All-Weather Operation: From the humid tropics to freezing winters, our plants keep running when others shut down for cleaning.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.