Coal Crushing Plant

CSTMG coal crushing plant delivers high-efficiency, low-maintenance coal processing. Our robust system features mineral sizers, crushers, and screens for optimal size reduction with 30% lower energy use. Designed for wet/sticky coal, it minimizes clogging and dust. Modular design enables fast deployment, while smart controls optimize output. Trusted in harsh mining conditions (-30°C to 50°C), our plants boost productivity while cutting costs.

CSTMG Coal Crushing Plant Structure

CSTMG’s coal crushing plants feature a robust, modular structure designed for maximum productivity even in harsh mining conditions. The system integrates primary crushing with mineral sizers or jaw crushers, secondary/tertiary crushing using roll or impact crushers, and efficient screening with banana screens – all connected by heavy-duty apron feeders and corrosion-resistant conveyors. Our intelligent PLC control center enables real-time monitoring and remote diagnostics.

Available in customized configurations for underground or open-pit operations, our plants handle everything from high-sulfur coal to mobile installations with optimal efficiency.

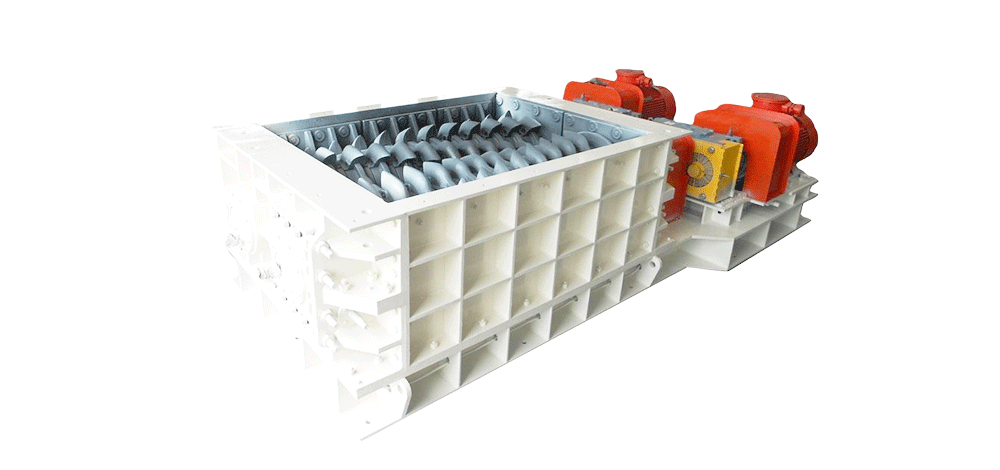

Feeding

Our advanced feeding system delivers precise material control through heavy-duty apron or belt feeders, featuring impact-resistant Hardox 400 pans, hydraulic tensioning for alignment stability, and dust-proof skirtboards with replaceable seals. Our smart load sensors prevent overfeeding while optional configurations include vibrating feeders for sticky materials, heat-resistant designs for hot clinker, and explosion-proof motors for coal operations.

Types of Feeding Equipment

Crushing

CSTMG coal crushing system features dual-stage crushing with mineral sizers (primary) and hammer crushers (secondary), achieving 0-50mm output at 500-3000tph. Includes anti-clogging teeth, dust-proof enclosures, and VFD drives for energy savings. Designed for high-moisture coal with <5% fines generation. Optional pre-screening and smart load control available.

Types of Crushing Equipment

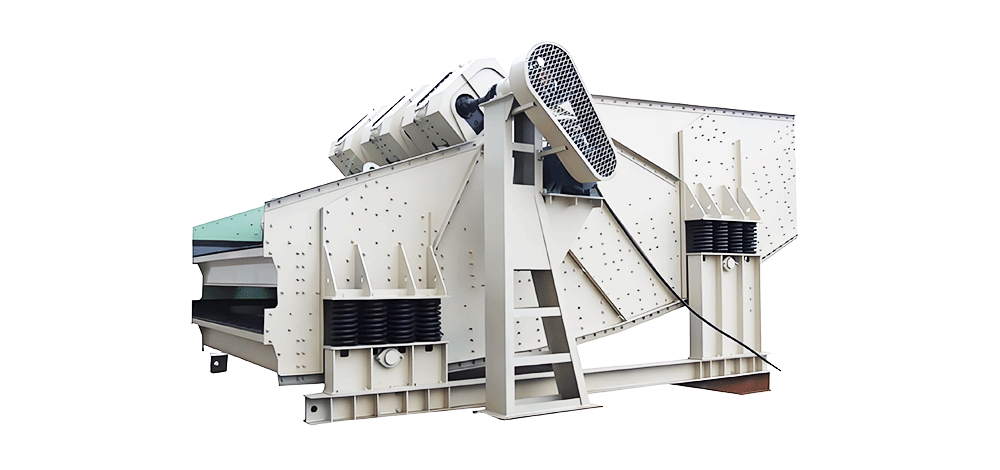

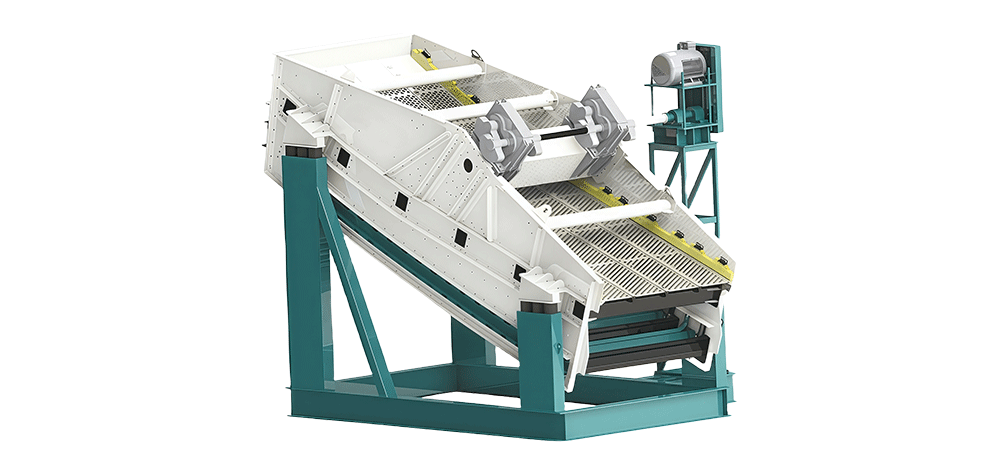

Screening

CSTMG coal screening system utilizes banana screens (other screening equipment optional) with polyurethane decks for high-efficiency 0-50mm classification at 3000tph. Features 25° adjustable slope, non-clogging design, and dust-tight enclosures. Includes smart vibration monitoring and quick-release tensioners for <30min panel replacement.

Types of Screening Equipment

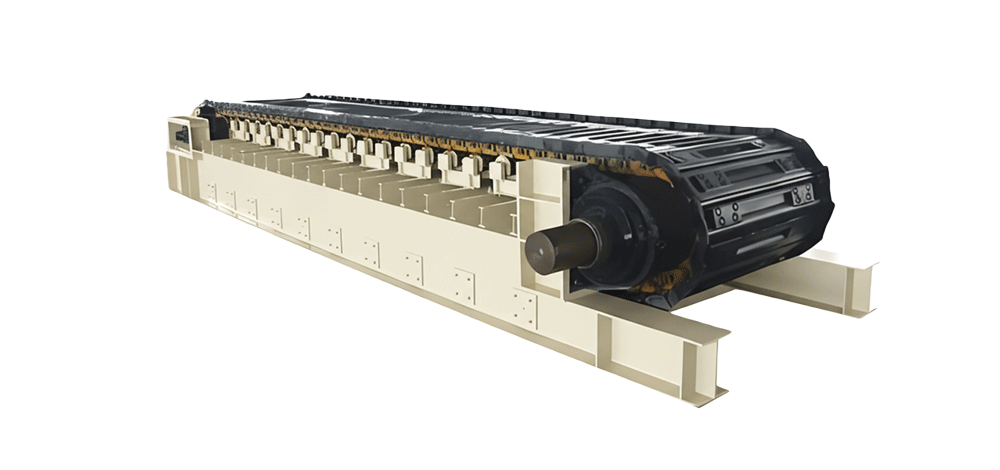

Conveying

CSTMG conveying system integrates heavy-duty belt conveyors, drive units, and self-aligning rollers for efficient material transport. Features V-grooved drive drums, impact-resistant idlers, and polyurethane cleaners to ensure smooth operation. Designed for high-capacity coal handling with dust-proof skirts and rip detection. Optional arctic-grade and fire-resistant configurations available.

Types of Conveying Equipment

Coal Crushing Output

CSTMG delivers fully customized coal crushing plants tailored to your exact production needs. Our engineered solutions adapt to your specific coal characteristics—whether processing high-moisture lignite, abrasive anthracite, or sulfur-rich thermal coal. We precisely configure each crushing stage (primary sizers, secondary roll crushers, and tertiary impactors) to achieve your target output size, while minimizing fines generation.

Intelligent automation ensures optimal throughput with real-time particle size monitoring. From compact modular designs for space-constrained sites to heavy-duty plants for mega mines, we integrate dust suppression, explosion-proofing, and energy recovery systems.

Coarse Coal

Mid-Size Coal

Fine Coal

Coal Powder

Application Industry

Advantages

As an industry leader with 60+ patents and ISO 9001 certification, CSTMG combines cutting-edge engineering with decades of mining expertise to deliver superior coal crushing solutions.

Our plants feature high-efficiency mineral sizers and smart automation, ensuring precise output sizing with <5% fines generation and throughput up to 5,000 TPH. Designed for harsh conditions, they incorporate tungsten carbide teeth (3x longer wear life), dust-proof enclosures, and arctic/desert packages (-40°C to 50°C). With 30% lower energy use and remote monitoring, we maximize uptime while minimizing costs.

Hot Mining Crushing and Screening Equipment

Apron Feeder

Length (m): 2-20

Capacity (m³/h): 50-4,000

Max feeding size (mm): 350-1,800

Feeder Breaker

Capacity (t/h): 500-5,000

Conveyor length (m): 6-30

Conveyor width (mm): 1,350-2,750

Mineral Sizer

Output size (mm): 50-300

Capacity (t/h): 250-10,000

Max feed size(mm): 200-1,500

Banana Screen

Capacity (t/h): 50-2,500

Max. Screen Width (mm): 4,300

Max. Screen Length (mm): 8,500

Roller Screen

Capacity (t/h): 150-1,800

Screen Width (mm): 1,200-2,400

Graded Particle Size (mm): 10-100

Flip Flow Screen

Capacity (t/h): 150-1,400

Feed size (mm): ≤80-≤100

Type: Mechanical/Vibrating

Circular Vibrating Screen

Number of Layers: 2-3

Capacity (t/h): 60-1,500

Max Input Size (mm): 200

Linear Vibrating Screen

Number of Layers: 1-2

Capacity (t/h): 40-950

Max Input Size (mm): 100

Jaw Crusher

Output size (mm): 70-300

Capacity (t/h): 130-1,150

Max feed size(mm): 560-960

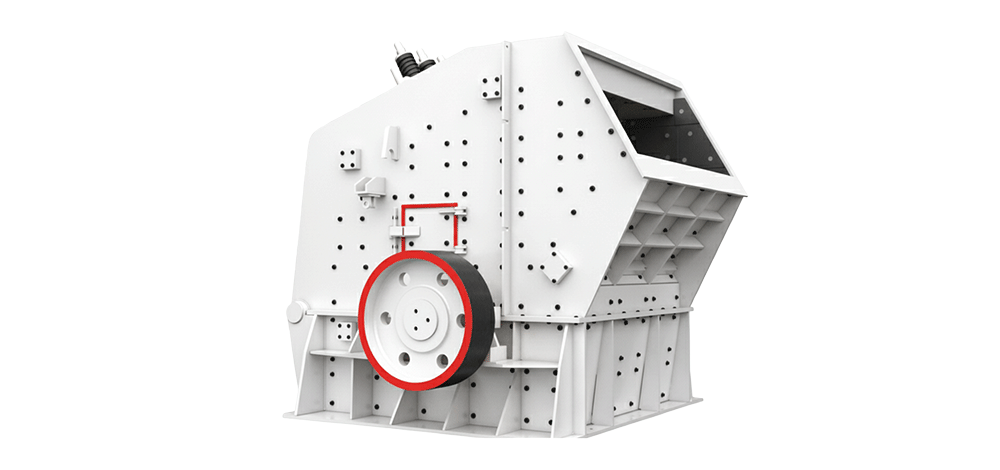

Impact Crusher

Rotor dia (mm): 1,300-1,600

Capacity (t/h): 300-1,000

Max feed size(mm): 600-800

Cone Crusher

Capacity (t/h): 27-1,270

Min. discharge size (mm): 9-38

Type: Single / Multi Cylinder

Hammer Crusher

Rotor dia (mm): 1,600-3,000

Capacity (t/h): 200-5,500

Max feed size(mm): ≤700-≤1,100

VSI Crusher

Capacity (t/h): 120-520

Soft material max. feed size (mm): 35-60

Hard material max. feed size (mm): 30-50

CSTMG Global Cases

Coal Crusher Plant Works in Indonesia

Crushing and Screening Plant Works in Namibia

CSTMG Crushing Plant Operates in Fiji

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.