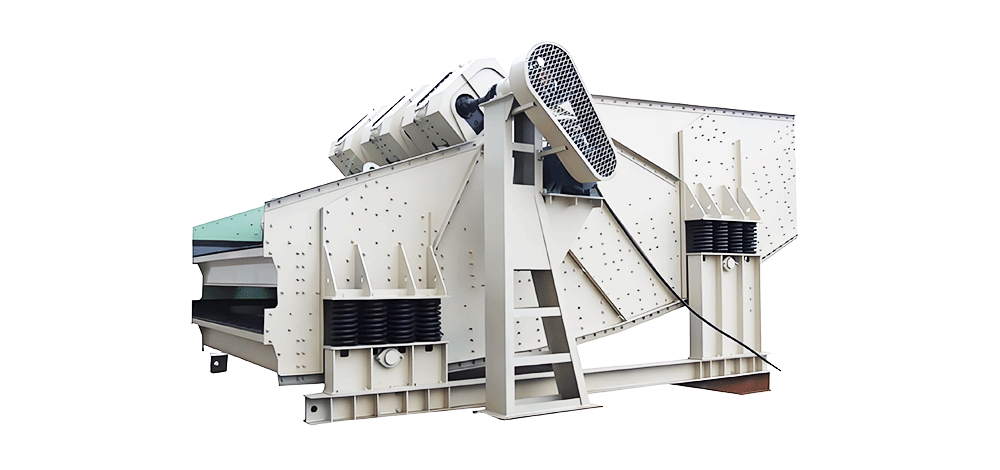

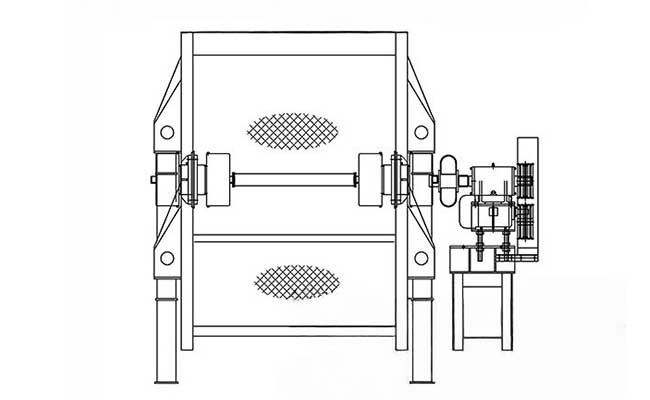

Circular Vibrating Screen

CSTMG circular vibrating screen is a versatile screening machine that uses a circular motion to separate materials by size. Driven by an eccentric shaft vibration exciter, it efficiently processes dry or wet materials across single or multiple decks. Ideal for mining, aggregates, and recycling, it offers high screening accuracy, large capacity, and low maintenance. Its robust design handles everything from fine powders to coarse aggregates, making it essential for classification, scalping, and dewatering applications in various industries.

APPLICATIONS

Coal

Mining

Recycling

CSTMG Circular Vibrating Screen Features

High Screening Efficiency. Multi-layer decks and adjustable vibration parameters ensure precise material separation with minimal energy consumption.

Robust Construction. Heavy-duty steel frame and reinforced side plates withstand harsh operating conditions and heavy material loads.

Versatile Applications. Handles dry, wet, fine, or coarse materials—ideal for mining, aggregates, recycling, and chemical industries.

Adjustable Amplitude/Frequency. Customizable vibration intensity optimizes material flow for different feed rates and particle sizes.

Smooth Operation. Precision-balanced vibrators and vibration exciters reduce noise and vibration transmission for stable, long-lasting performance.

CSTMG Circular Vibrating Screen Specification

| Model | Screen Plate | Max. Input Size | Capacity | Electrical Motor | |||

| Layer(s) | Area(m²) | Mesh Size(mm) | (mm) | (t/h) | Power(kw) | Qty(pcs) | |

| CSTMG – 2SYKH2160 | 2 | 12.6×2 | 3-80 | 200 | 60-400 | 30 | 1 |

| CSTMG – 3SYKH2160 | 3 | 12.6×3 | 3-80 | 200 | 60-400 | 37 | 1 |

| CSTMG – 2SYKH2460 | 2 | 14.4×2 | 3-80 | 200 | 90-500 | 37 | 1 |

| CSTMG – 3SYKH2460 | 3 | 14.4×3 | 3-80 | 200 | 90-500 | 37 | 1 |

| CSTMG – 2SYKH3075 | 2 | 22.5×2 | 3-80 | 200 | 150-700 | 37 | 1 |

| CSTMG – 3SYKH3075 | 3 | 22.5×3 | 3-80 | 200 | 150-700 | 30 | 2 |

| CSTMG – 2SYKH3685 | 2 | 30.6×2 | 3-80 | 200 | 180-1100 | 45 | 2 |

| CSTMG – 3SYKH3685 | 3 | 30.6×3 | 3-80 | 200 | 180-1100 | 55 | 2 |

| CSTMG – 2SYKH40100 | 2 | 40×2 | 3-80 | 200 | 210-1500 | 75 | 2 |

| CSTMG – 3SYKH40100 | 3 | 40×3 | 3-80 | 200 | 210-1500 | 75 | 2 |

CSTMG Circular Vibrating Screen Worldwide Cases

CSTMG Circular Vibrating Screen Works in Egypt

CSTMG Circular Vibrating Screen Delivered to South Africa

CSTMG Circular Vibrating Screen Success Operates in Russia

CSTMG Circular Vibrating Screen Operates in Saudi Arabia

CSTMG Circular Vibrating Screen Delivered to Brazil

CSTMG Circular Vibrating Screen Success Operates in Ghana

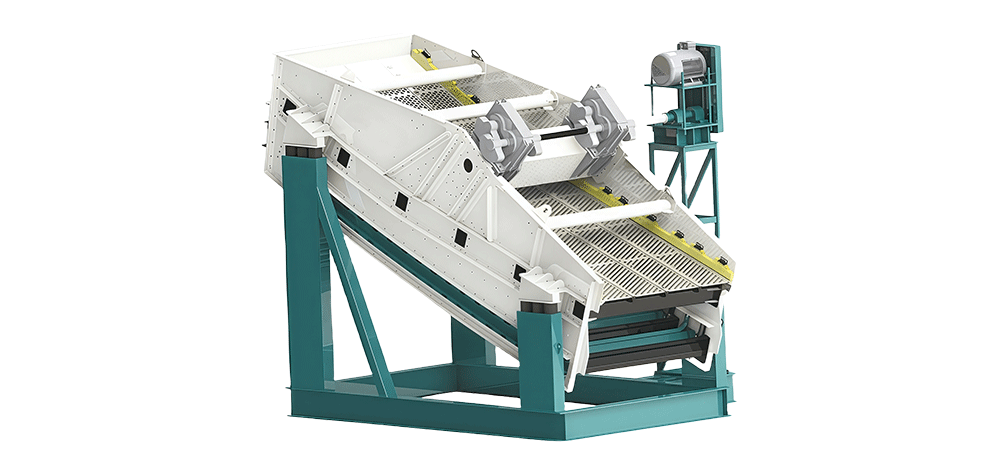

Circular Vibrating Screen Handling Materials

Metal Ores Processing. Circular screens efficiently classify iron, copper, and gold ores after crushing. They separate coarse fragments (for recrushing) from fine particles (ready for beneficiation).

Coal Classification. Essential in coal preparation plants, these screens sort raw coal into lump coal (for power generation) and fine coal (for coking/gasification).

Aggregates Grading. Can precisely separate crushed limestone, granite, and basalt into specified sizes for concrete (0-5mm sand, 5-20mm gravel) and asphalt mixtures

Industrial Minerals. Great at processing quartz sand (for glass/ceramics), kaolin, and feldspar, removing impurities and grading particles to industry standards.

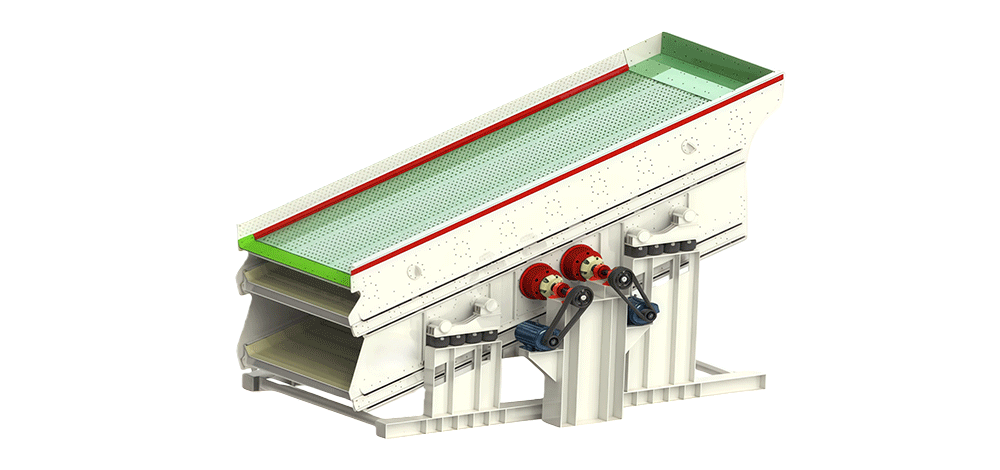

CSTMG Circular Vibrating Screen Production Details

Advanced Screening Capabilities

- Multi-Layer Classification: Configurable with 1–4 decks (e.g., 4-layer models for quarry aggregates: 0–5mm, 5–10mm, 10–20mm, 20–40mm) to replace multiple single-deck screens.

- Customizable Apertures: Offers round, square, or slotted openings (2–150mm) for optimal material passage—slotted screens excel with flaky minerals like mica or graphite.

Reliable Drive System

- Dual-Shaft Synchronization: Uses twin exciters with gear/synchronous belt drives to ensure perfectly balanced vibration, eliminating torque differences for smooth, consistent material flow.

- Flexible Motor Options: Supports left/right-side motor mounting with power ratings from 5.5kW to 45kW, adaptable to varying capacity (50–800 t/h) and space constraints.

Robust Structural Design

- High-Strength Screen Box: Made from DH36 alloy steel plates, with side panels and beams connected via grooved rivets or high-strength bolts (instead of welding) to prevent stress concentration, enhancing fatigue resistance and durability under heavy vibration loads.

- Modular Components: Features quick-release screen meshes, vibration exciters, and sealing systems for fast replacement, minimizing downtime during maintenance.

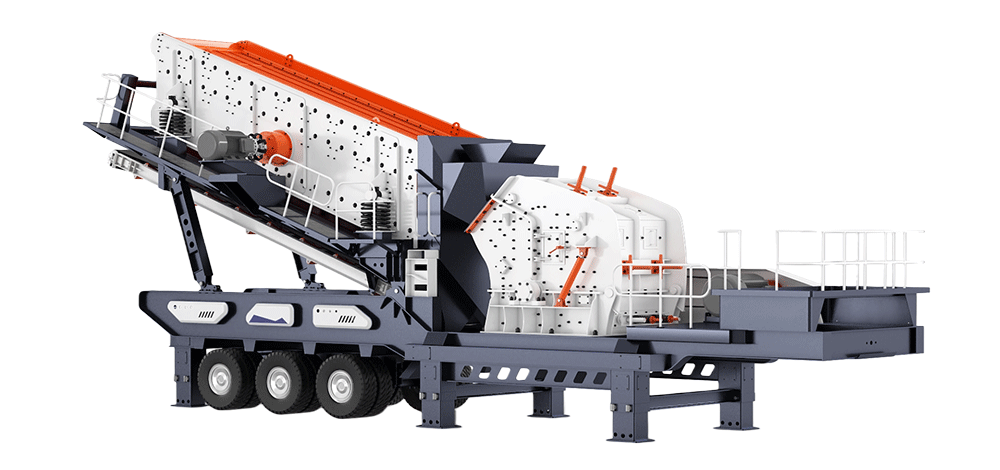

CSTMG Linear Vibrating Screen Working Principle

The circular vibrating screen operates through a precisely engineered system of mechanical vibration and material stratification. At its core, the machine utilizes an eccentric shaft vibration exciter to generate centrifugal force, which drives the entire screen body into a circular or elliptical motion. This motion creates a dynamic sieving action that efficiently separates materials by size while simultaneously conveying them across the screen surface.

When the motor activates the exciter, the rotating eccentric weights produce a powerful centrifugal force, causing the screen frame to vibrate in a stable, circular pattern. The screen’s inclination angle (typically 15°-25°) and vibration amplitude (adjustable between 4-12mm) work together to propel materials forward while allowing finer particles to pass through the mesh openings. As materials enter the feed end, they undergo a continuous cycle of throwing, stratification, and penetration—coarse particles travel along the screen surface to the discharge end, while fines drop through the apertures into designated collection points.

The system’s efficiency is enhanced by multi-layer screening decks (up to 4 layers), which enable simultaneous classification of materials into multiple size fractions in a single operation. Rubber damping springs isolate vibrations, protecting the structural integrity of both the machine and its foundation. This combination of high-frequency vibration, optimized screen inclination, and modular deck configuration makes circular vibrating screens ideal for heavy-duty applications in mining, aggregates, and industrial processing.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.