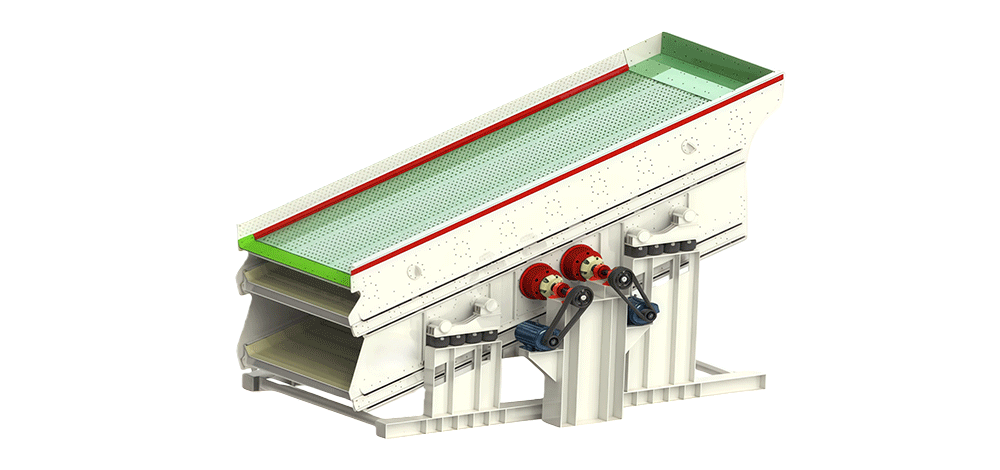

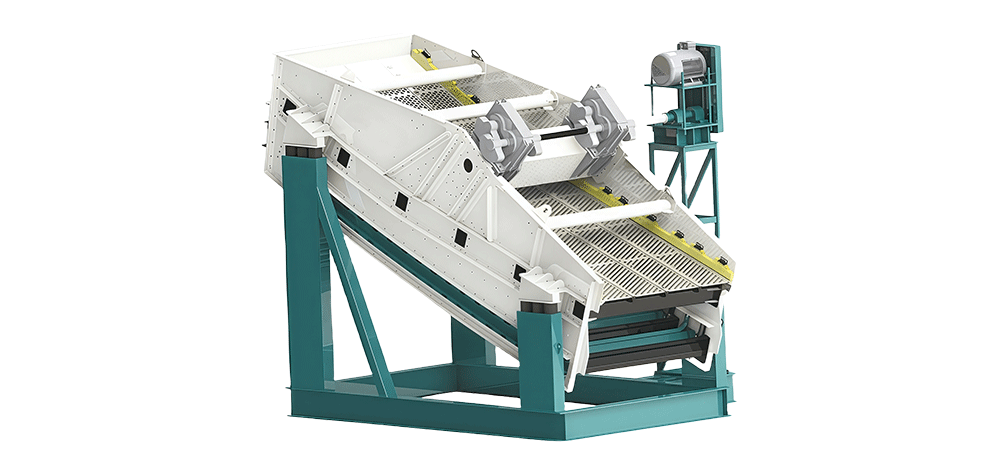

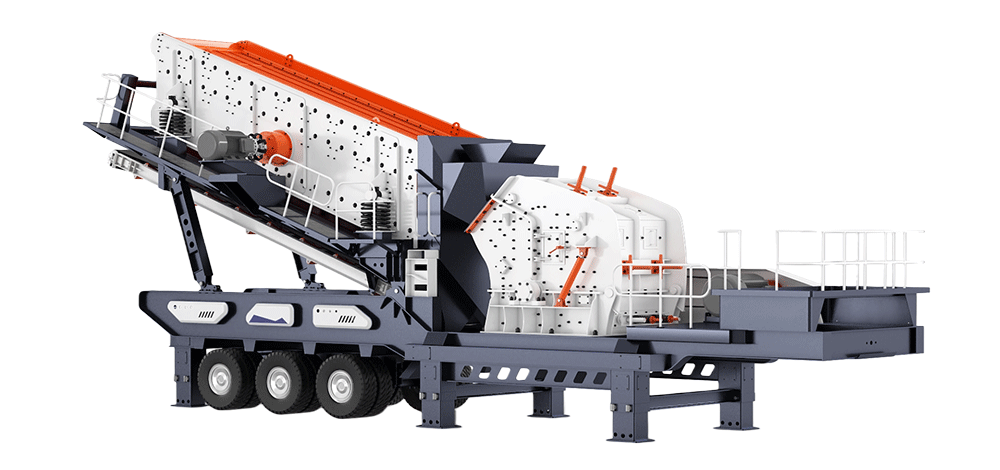

Banana Screen

CSTMG’s banana screen revolutionizes coal and mineral classification with multi-slope deck technology, ensuring uniform material distribution and high screening efficiency (up to 95%). Designed for high-capacity operations (up to 2,500 TPH), it features polyurethane/nylon decks for extended wear life and anti-clogging performance. Ideal for wet, sticky, or dry materials, it reduces fines loss and energy consumption by 20%.

APPLICATIONS

Coal

Mining

CSTMG Banana Screen Features

Multi-Slope Screening. Unique 3-stage deck angles (30°→10°) maintain uniform material thickness, boosting throughput 1.5-2x vs flat screens while reducing fines loss.

Wet/Dry Versatility. Polyurethane/nylon decks handle 0-25% moisture coal seamlessly, with anti-clogging design for slurry or dry applications.

Smart Vibration Tech. Dual exciters with elliptical-to-circular motion optimize material stratification and prolong screen contact time for 95%+ efficiency.

Heavy-Duty Build. Gear-synchronized exciters (20,000h lifespan) + riveted steel frame withstand 8g vibration, ideal for iron ore/coal 24/7 ops.

Energy-Saving Design. CSTMG special vibration exciters reduce power use by 20% versus traditional screens, cutting operational costs without sacrificing performance.

CSTMG Banana Screen Specification

| Model | Screen Plate | Max. Input Size | Capacity | Electrical Motor | |||

| Layer (s) | Area (m²) | Mesh Size (mm) | (mm) | (t/h) | Power(kw) | Qty(pcs) | |

| CSTMG – ZXF2461 | 1 | 14.64 | 0.5-80 | 300 | 40-550 | 37 | 1 |

| CSTMG – 2ZXF2461 | 2 | 14.64×2 | 0.5-80 | 300 | 40-650 | 45 | 1 |

| CSTMG – ZXF3061 | 1 | 18.3 | 0.5-80 | 300 | 60-650 | 45 | 1 |

| CSTMG – 2ZXF3061 | 2 | 18.3×2 | 0.5-80 | 300 | 60-750 | 55 | 1 |

| CSTMG – ZXF3661 | 1 | 21.96 | 0.5-80 | 300 | 80-850 | 55 | 1 |

| CSTMG – 2ZXF3661 | 2 | 21.96×2 | 0.5-80 | 300 | 80-950 | 75 | 1 |

| CSTMG – ZXF4361 | 1 | 26.23 | 0.5-80 | 300 | 100-1200 | 55 | 1 |

| CSTMG – 2ZXF4361 | 2 | 26.23×2 | 0.5-80 | 300 | 100-1300 | 75 | 1 |

CSTMG Banana Screen Worldwide Cases

CSTMG Banana Screen Works in Georgia

CSTMG Banana Screen Test For Cameroon Customer

CSTMG Banana Screen Deliver to Zambia

Banana Screen Handling Materials

Coal & Carbon-Based Materials. Banana screens efficiently separate coal from impurities using multi-slope decks that prevent clogging. They dewater lignite and classify metallurgical coke with wear-resistant surfaces, while optimizing coal gangue recovery in mining operations.

Metallic Ores. These screens process abrasive iron/copper ores with precision sizing for smelting. Their robust construction handles dense manganese/nickel ores, while specialized decks preserve bauxite integrity during alumina production classification.

Industrial Minerals. For limestone processing, banana screens provide accurate grading with abrasion-resistant panels. They gently classify gypsum with minimal dust, efficiently size phosphate rock, and handle corrosive salt environments using specialized materials.

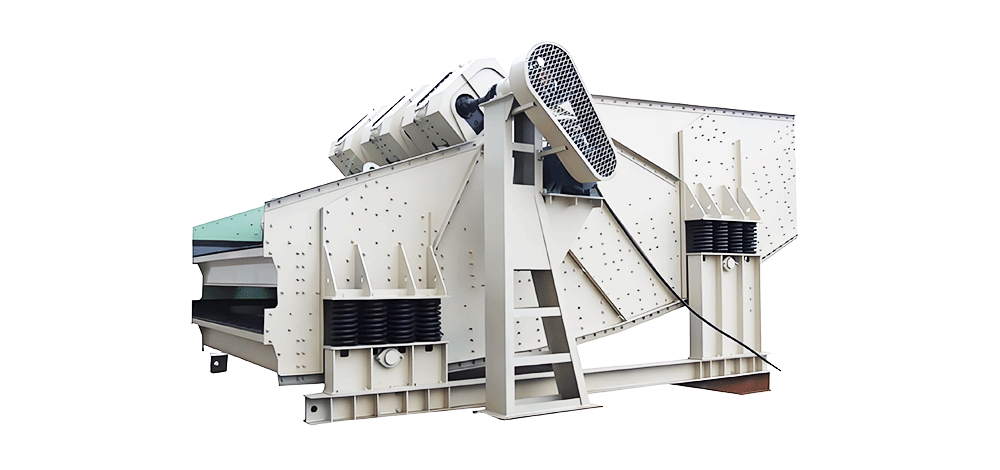

CSTMG Banana Screen Production Details

Design & Engineering

- CSTMG banana screens feature multi-slope, equal-thickness screening technology, optimized through 3D modeling and finite element analysis (FEA) for structural integrity and vibration efficiency.

Key Components

- Screen Box: High-strength Q345B steel with laser-cut panels for precision.

- Beams: Rectangular hollow-section (RHS) crossbeams with polyurea/rubber linings for wear resistance.

- Vibration Exciter: Oil-lubricated, gear-driven with SKF/FAG bearings for high torque and durability.

- Screen Decks: Modular polyurethane/wire mesh panels (interchangeable for different materials).

- Damping System: Steel coil springs for stable operation under heavy loads.

CSTMG Banana Screen Working Principle

Our banana screen operates on an advanced multi-slope stratification principle, featuring 3-5 deck sections with gradually decreasing angles from 35° at the feed end to 10° at discharge. This innovative design accelerates material flow initially for rapid particle stratification, then slows movement to ensure complete screening.

The screen achieves equal-thickness screening by maintaining a uniform 20-50mm material layer across the deck, allowing fine particles to sink for direct mesh contact while coarse particles migrate to the surface.

Dual-frequency vibration combines high-frequency (15-20Hz) excitation for material fluidization with low-frequency (5-10Hz) motion for gentle conveyance.

The system features distinct functional zones: a 35° acceleration zone prevents feed-end overload, a 25° primary screening zone maximizes fines recovery, and a 15° finishing zone reduces misplaced particles.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.