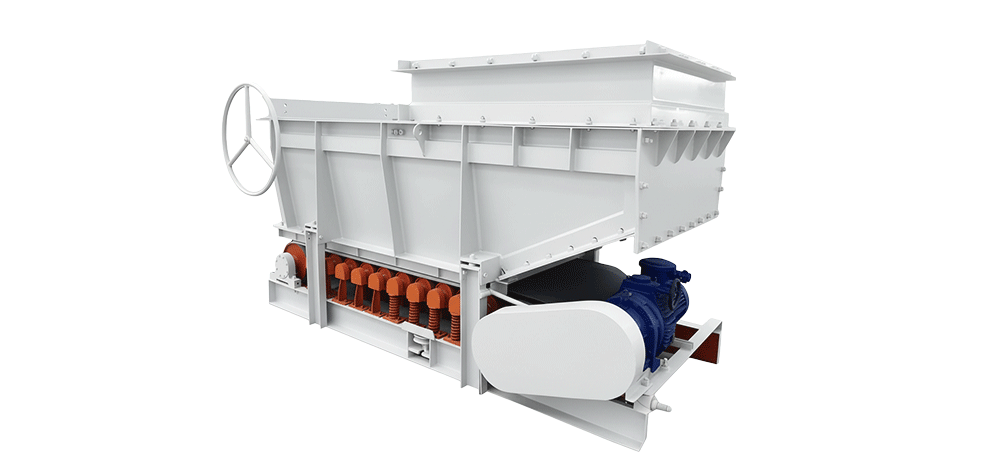

Apron Feeder

CSTMG apron feeder is a heavy-duty material handling machine designed for controlled feeding of bulk materials in mining, cement, and aggregate industries. Featuring overlapping metal pans driven by robust chains, it handles large, abrasive, or hot materials (up to 3000t/h capacity) without spillage. Its rugged construction withstands impact loads from crushers or hoppers, while variable speed drives enable precise feed rate adjustment. Ideal for uneven or oversized materials, apron feeders ensure continuous, reliable operation in harsh conditions with minimal maintenance.

APPLICATIONS

Coal

Mining

Aggregates

Concrete

CSTMG Apron Feeder Features

Heavy-Duty Construction. Built with reinforced steel pans and forged chains to handle large, abrasive materials (up to 2000mm size) in mining and quarrying applications.

Material Versatility. Handles diverse materials—lumps, powders, wet/sticky ores—without clogging or spillage, adapting to limestone, iron ore, or coal.

Precise Feed Control. Variable speed drives (mechanical or hydraulic) enable adjustable feed rates (±5% accuracy) for crushers or conveyors downstream.

Impact Resistance. Overlapping pans absorb shock loads from dump trucks or hoppers, protecting equipment from damage in harsh mining conditions.

High Capacity. Designed for throughputs up to 3000 t/h, ideal for bulk material handling in cement, coal, and mineral processing plants.

CSTMG Apron Feeder Specification

| Model | Feeding Capacity (m³/h) | Pan Width (mm) | Pan Length (mm) | Feeding Speed (m/s) | Feeding Size (mm) |

| CSTMG – ZBWJ1200 | 100-600 | 1200 | 3-50 | 0.02-0.19 | ≤600 |

| CSTMG – ZBWJ1400 | 100-800 | 1400 | 3-50 | 0.02-0.19 | ≤800 |

| CSTMG – ZBWJ1600 | 200-1000 | 1600 | 3-50 | 0.02-0.19 | ≤1000 |

| CSTMG – ZBWJ1800 | 400-1500 | 1800 | 3-50 | 0.02-0.25 | ≤1000 |

| CSTMG – ZBWJ2000 | 600-2000 | 2000 | 3-50 | 0.02-0.25 | ≤1200 |

| CSTMG – ZBWJ2400 | 800-3000 | 2400 | 3-50 | 0.02-0.25 | ≤1400 |

| CSTMG – ZBWJ2800 | 1300-4000 | 2800 | 3-50 | 0.03-0.36 | ≤1800 |

CSTMG Apron Feeder Worldwide Cases

CSTMG Apron Feeder Installation in Mongolia

CSTMG Apron Feeder Installation in Kenya

CSTMG Apron Feeder Installation in Namibia

Apron Feeder Handling Materials

Metal Ores. Apron feeders excel in transporting metal ores such as iron ore (magnetite, hematite), copper ore (chalcopyrite, bornite), and gold ore (quartz veins, sulfide ores).

Non-Metallic Minerals. For non-metallic minerals like limestone, dolomite, and marble/granite, apron feeders provide reliable material handling.

Coal & Carbon Materials. In coal and carbon material applications, apron feeders deliver run-of-mine coal (≤1500mm) to wash plants or crushers, handling high moisture content (≤15%) without slippage.

Aggregates & Quarry Stone. Apron feeders are ideal for aggregate and quarry stone operations, feeding hard rock like basalt and granite (≤2000mm) to jaw or cone crushers.

CSTMG Apron Feeder Production Details

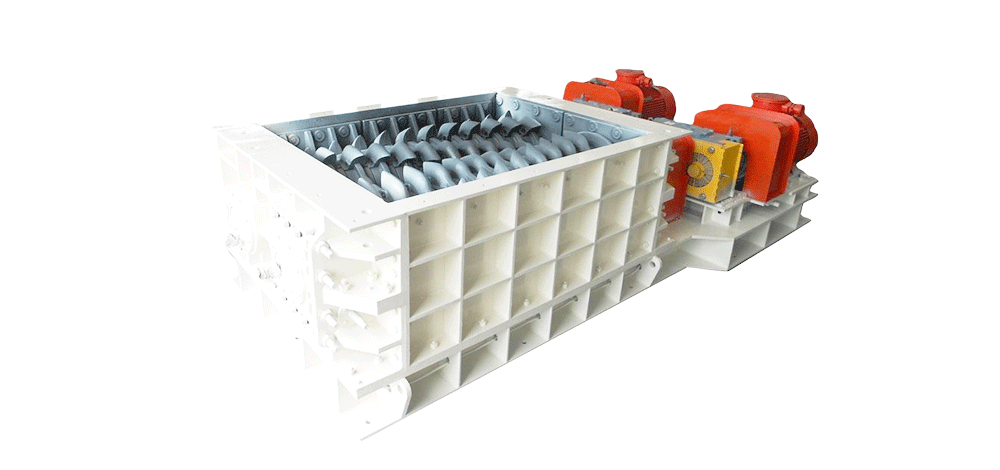

Pan & Chain System

- Forged alloy steel pans (16Mn or ZGMn13) with replaceable liners resist abrasion from iron ore, copper slag, and other harsh materials. Pan thickness ranges from 20-50mm based on application severity.

- Sealed roller chains (ISO 1977 standard) with hardened pins and bushings provide 3-5x longer lifespan than conventional chains in high-wear environments. Self-lubricating designs are available for dusty conditions.

Drive & Transmission

- Dual-motor drive with synchronized gear reducers delivers 15-500kW power, enabling capacities up to 7,000 t/h.

- Flexible speed control: Variable frequency drives (VFDs) allow feed rate adjustments from 0.01-0.3 m/s with ±2% accuracy.

- Dual transmission options: Chain/sprocket system for heavy-impact applications (e.g., primary crushing); Gear-driven system for precise, low-maintenance operation (e.g., cement plants)

Tensioning & Protection

- Hydraulic auto-tensioning maintains optimal chain tension, preventing slippage and reducing power consumption by 10-15%.

- Integrated safety features: Overload torque limiters, emergency stop pull cords, dust-proof motor enclosures (IP65 rating)

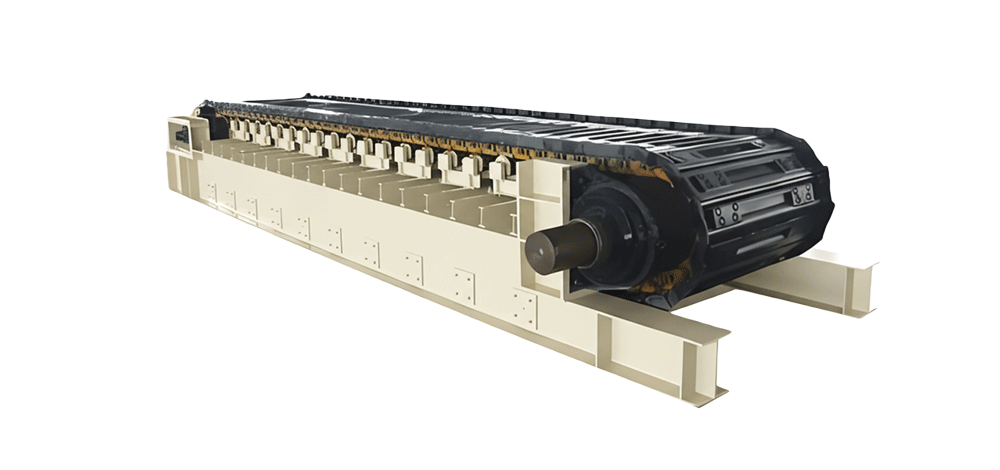

CSTMG Apron Feeder Working Principle

The apron feeder operates through a robust mechanical system designed for controlled material transport in heavy-duty applications. At its core, the system utilizes motor-driven chains and overlapping steel pans to create a continuous moving platform for bulk materials.

Power Transmission begins with an electric motor (typically 15-500kW) that delivers rotational energy to a gear reducer. This reducer converts high-speed, low-torque input into the low-speed, high-torque output needed to drive massive loads. The torque is transferred via couplings to sprockets, which engage with heavy-duty roller chains.

Material Conveyance occurs as the chains pull interconnected pans forward in a linear path. Pans are engineered with overlapping edges to prevent material leakage, while their deep profiles accommodate large lumps (up to 2,000mm). As pans move from the feed hopper to the discharge point, they carry materials like iron ore or coal at controlled speeds (0.01-0.3 m/s), adjustable via VFDs.

Inquiry Now

To help us recommend the optimal mineral sizer solution for your operation, please provide:

- your project location and application;

- material type, feed size, moisture and hardness;

- required capacity and target output size; current equipment challenges (if any);

- and any special requirements like dust control or space limitations.

Including your contact details will enable our engineers to prepare a customized proposal with equipment specifications, layout recommendations, and performance estimates within 24 hours.

For fastest service, attach any available material test reports or site photos to your inquiry.