Business Strength

Technology Leadership

CSTMG maintains a rigorous quality management system and employs cutting-edge product testing methodologies. As an industry pioneer, we were among the first to obtain ISO9001 Quality Management System certification, consistently maintaining product quality at industry-leading levels. Our technological excellence is demonstrated through ownership of over 60 national patents and multiple awards, including prestigious national and provincial-level science and technology honors.

Smart Manufacturing

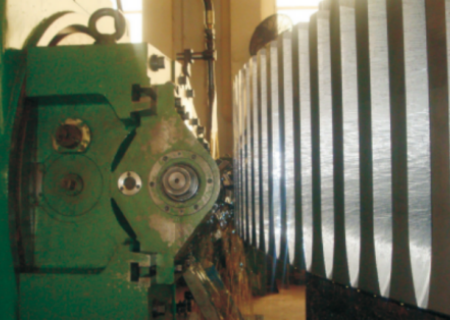

CSTMG excels in smart manufacturing with advanced processing equipment like Heavy Duty Vertical Lathesand CNC Plasma Cutting Machines, ensuring precision engineering. Our Electric Centralized Control Systemintegrates intelligent automation for crushing stations, featuring PLC-controlled GGD cabinets, soft starters, and variable frequency speed regulation for optimized production. From automated CNC processing to real-time monitoring with smart sensors, CSTMG combines cutting-edge technology with robust safety protocols (overload protection, emergency stops) to enhance efficiency and reliability in mining and heavy industries.

CSTMG

Lean Production

CSTMG has adopted lean production principles to maximize efficiency and minimize waste across our manufacturing operations. By implementing just-in-time material flows, automated precision machining, and intelligent inventory systems, we’ve streamlined production processes while maintaining rigorous quality standards. Our continuous improvement culture, supported by real-time IoT monitoring and employee-driven innovation, has achieved measurable results including 20% faster production cycles and 15% reduction in material waste.

These lean methodologies enhance our competitiveness in delivering high-performance heavy machinery while optimizing resource utilization throughout the production lifecycle.

Manufacturing Capacity

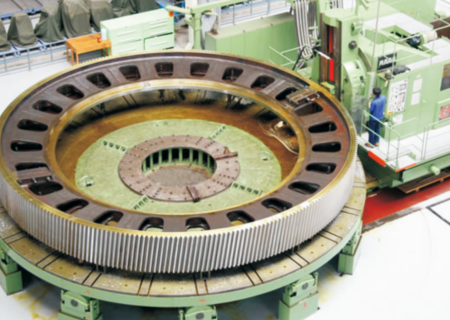

As a leading manufacturer of crushing, screening, and bulk material handling systems, CSTMG operates over 140 advanced manufacturing units, including Five-axis Gantry Machining Centers and CNC Horizontal Machining Centers. This cutting-edge infrastructure, supported by rigorous processing management systems, enables us to deliver large-scale orders and customized solutions with precision.

Our product portfolio spans high-capacity crushing/screening systems (up to 3,500 t/h for open-pit mines), specialized coal/oil shale processing lines (30,000 tons/day), and eco-friendly material handling systems – all certified with Mining Product Safety Marks and backed by multiple national patents.

From engineering design to commissioning, we integrate crushing, conveying, dust control, and smart automation into turnkey solutions for coal, ores, and industrial minerals.